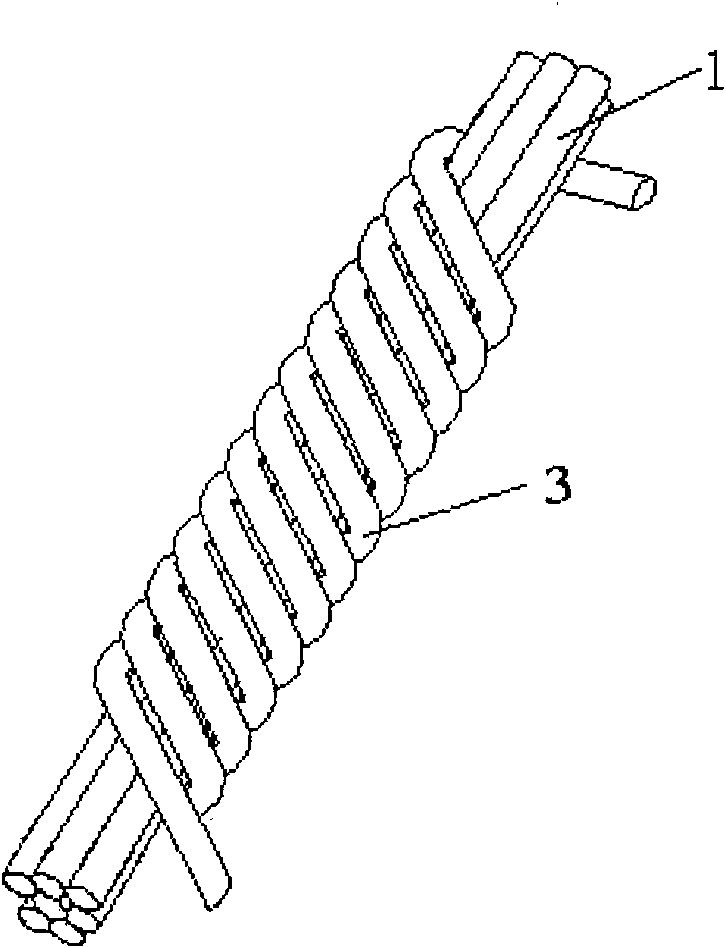

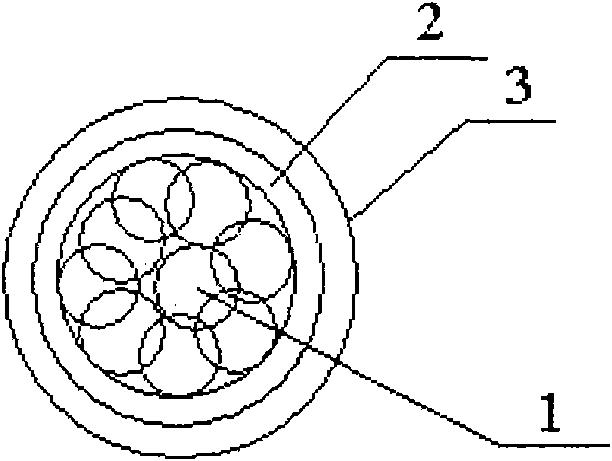

Composite filament of tencell, spun silk and modified synthetic fibers and preparation method thereof

A technology of synthetic fiber and composite yarn, which is applied in the field of composite yarn, can solve the problems that the strength of Tencel-spun silk composite yarn is unreasonable, cannot fully reflect the advantages, and cannot be processed, etc., to achieve strong mechanical properties, high strength, and high heat Effect of Stability and Flame Retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) Tencel adopts the conventional method: cleaning flowers - carding - pre-merged into a strip, and the quantification of a strip is 18 grams / 5 meters;

[0038] The silk sliver adopts the conventional method to draw and cut into b strips, and the quantification of b strips is 10 grams / 5 meters;

[0039] The mixture of tencel and spun silk adopts the conventional method: clearing - carding - pre-merging into c strips, and the quantitative is 15 grams / 5 meters.

[0040] Among them, the fineness of spun silk is 0.8dtex; the fineness of tencel is 1.2dtex;

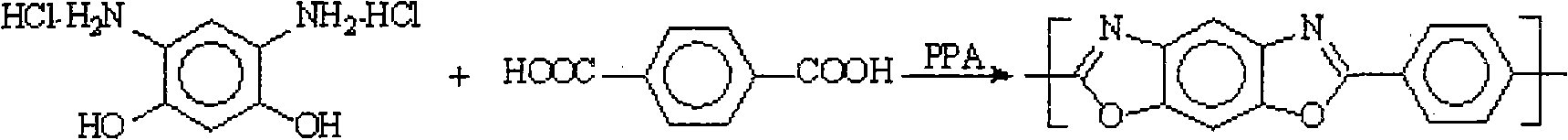

[0041] The p-phenylene benzobisoxazole fibers are pre-combined into a' strips in a conventional method, and the quantification is 15 grams / 5 meters.

[0042] The poly-p-phenylene benzobisoxazole fiber, tencel and spun silk are respectively made into pure p-phenylene benzobisoxazole fiber a', pure tencel a, pure spun silk b and phenylene benzobisoxazole Mixed c slivers of dioxazole fibers, tencel and spun silk are sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com