Composite silk and its preparing method

A composite silk and tencel technology, applied in textiles and papermaking, continuous winding spinning machines, open-end spinning machines, etc., can solve the problems that the advantages cannot be fully reflected, the processing cannot be used, and the fibers are mixed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Tencel adopts the conventional method: cleaning flowers - carding - pre-merging into a sliver, the quantification of a sliver is 18 grams / 5 meters;

[0029] 1# silk cotton strip adopts conventional method to draw and cut into b strip, and the quantification of b strip is 10 grams / 5 meters;

[0030] The mixture of tencel and spun silk adopts the conventional method: clearing - carding - pre-merging into c strips, and the quantitative is 15 grams / 5 meters.

[0031] Among them, the fineness of spun silk is 0.8dtex; the fineness of tencel is 1.2dtex

[0032] The temperature during spinning is 25°C and the relative humidity is 80%;

[0033] The output roller of the air-jet spinning had a linear speed of 195 m / min.

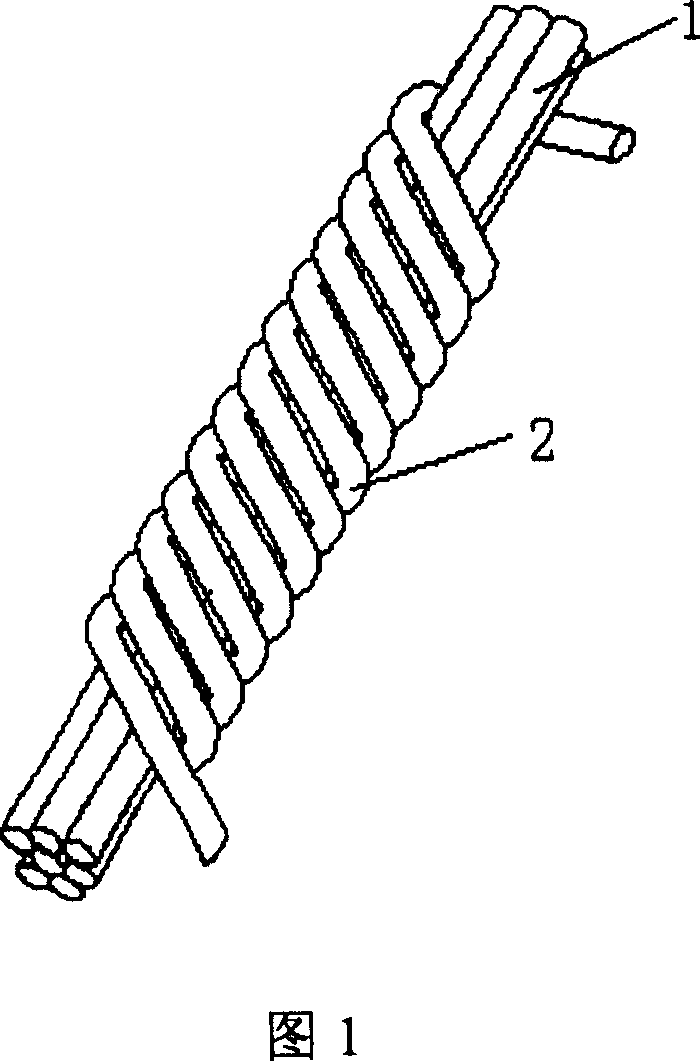

[0034] Promptly obtain the tencel-spun silk composite yarn of the present invention, its structure is shown in Figure 1. Adopt Q / WFAS016-2003 enterprise standard to test above-mentioned tencel-spun silk composite yarn, the result is as follows: excellent pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com