Method for production of paper strips braided wallpaper and product made thereby

A production method and technology of paper strips, applied in the direction of woven fabrics, textiles, papermaking, yarn, etc., can solve the problems of lack of natural feeling of products, and achieve the effects of low production cost, reasonable structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

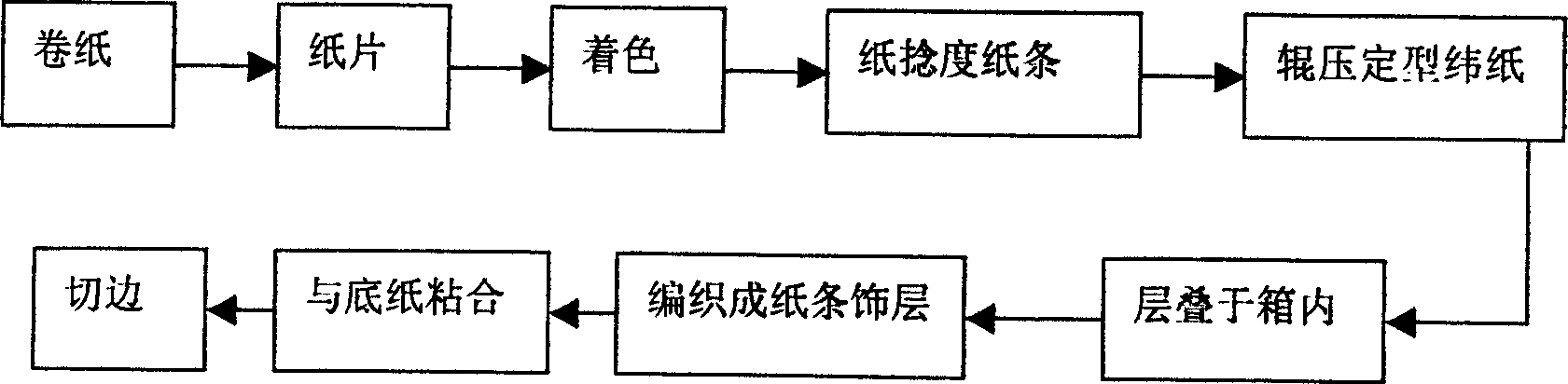

Method used

Image

Examples

Embodiment 1

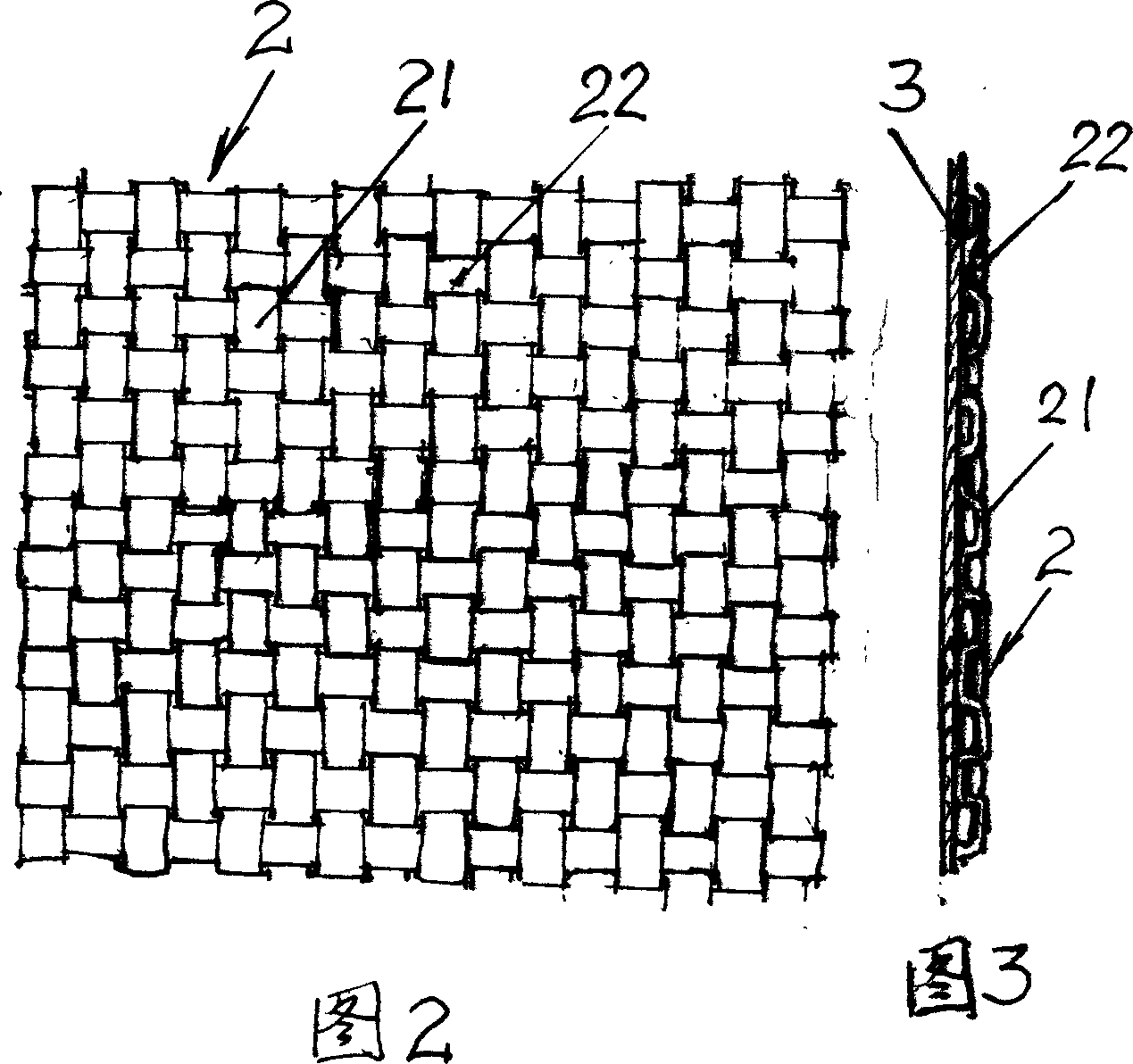

[0020] Embodiment 1: Select 30 grams of rolled paper to be rolled and cut into paper sheets with a width of 8mm on a paper cutter, and then automatically rolled on the paper tray; when necessary, dyeing water can be sprayed (or soaked) on one side of the paper tray, Then several paper discs are placed on the twisting machine to twist the low-twist paper strips with a twist of 30 twists / meter, which are wound in the bobbin; after the paper strips are rolled and shaped, they are randomly scattered on the In an open carton of about 500×500mm, so that it can be stacked on top of each other without causing confusion. At the same time, hundreds of paper strips are cut into a warp cylinder with a warp density of 4 strands / cm in the warp warp machine. During the warp warp process, about 50 kg of pressure rollers are pressed to keep the warp thread tight and uniform, and to make it There is a certain tension. The warp cylinder is placed on the improved magnetic control loom, and the w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com