Heating radiator for compressors

A compressor and radiator technology, applied in the field of radiators for compressors, can solve the problems of rising indoor temperature, low service life, poor heat exchange effect, etc., to increase the heat dissipation area, improve service life, and improve heat exchange effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below using the accompanying drawings and examples.

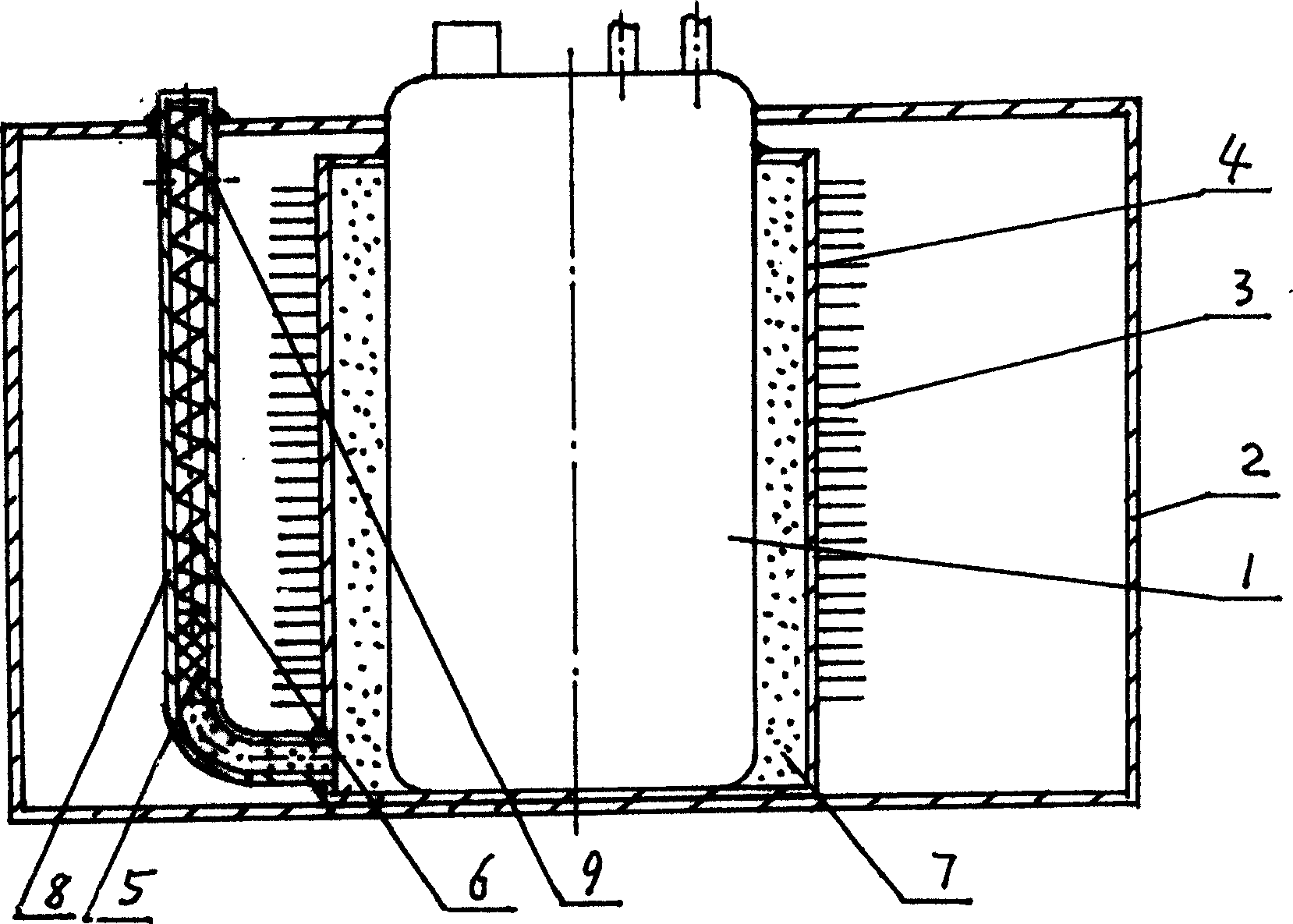

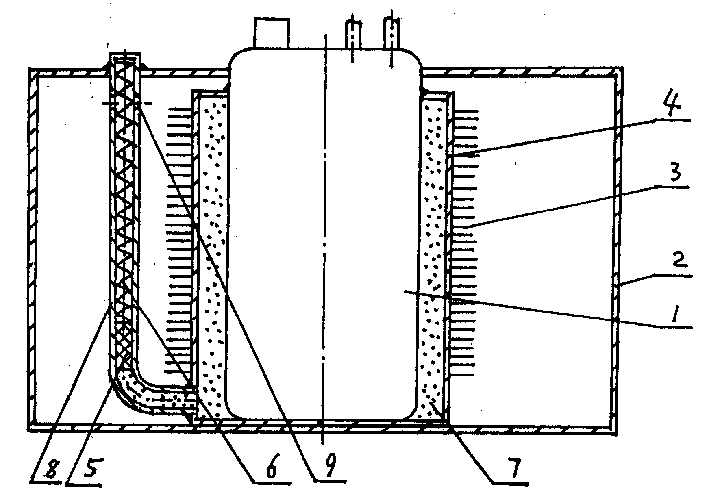

[0012] refer to figure 1 , the compressor radiator has vacuum heat exchange inner and outer barrels 4, 2, a compressor 1 is placed in the vacuum heat exchange inner barrel 4, the space between the compressor 1 and the vacuum heat exchange inner barrel 4 is filled with a heat exchange medium 7, and the vacuum The heat exchange inner barrel 4 communicates with the auxiliary vacuum heat exchange tube 8, and the porous body 5 and the reset elastic body 6 are arranged in the auxiliary vacuum heat exchange tube 8 to cool the heat exchange medium 7 back to its original position. The vacuum heat exchange inner barrel 4 is placed in the vacuum heat exchange outer barrel 2 . The vacuum heat exchange inner barrel 4 communicates with the auxiliary vacuum heat exchange tube 8, and the vacuum heat exchange tube 8 forms a heat radiation path with the vacuum heat exchange outer barrel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com