Double pad oxide technique for processing shallow trench isolation

A shallow trench isolation and oxide technology, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems that the pad oxide thickness should not be too thick, the pad oxide should not be too thin, and rough

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Preferred embodiments of the present invention are described below with reference to the accompanying drawings.

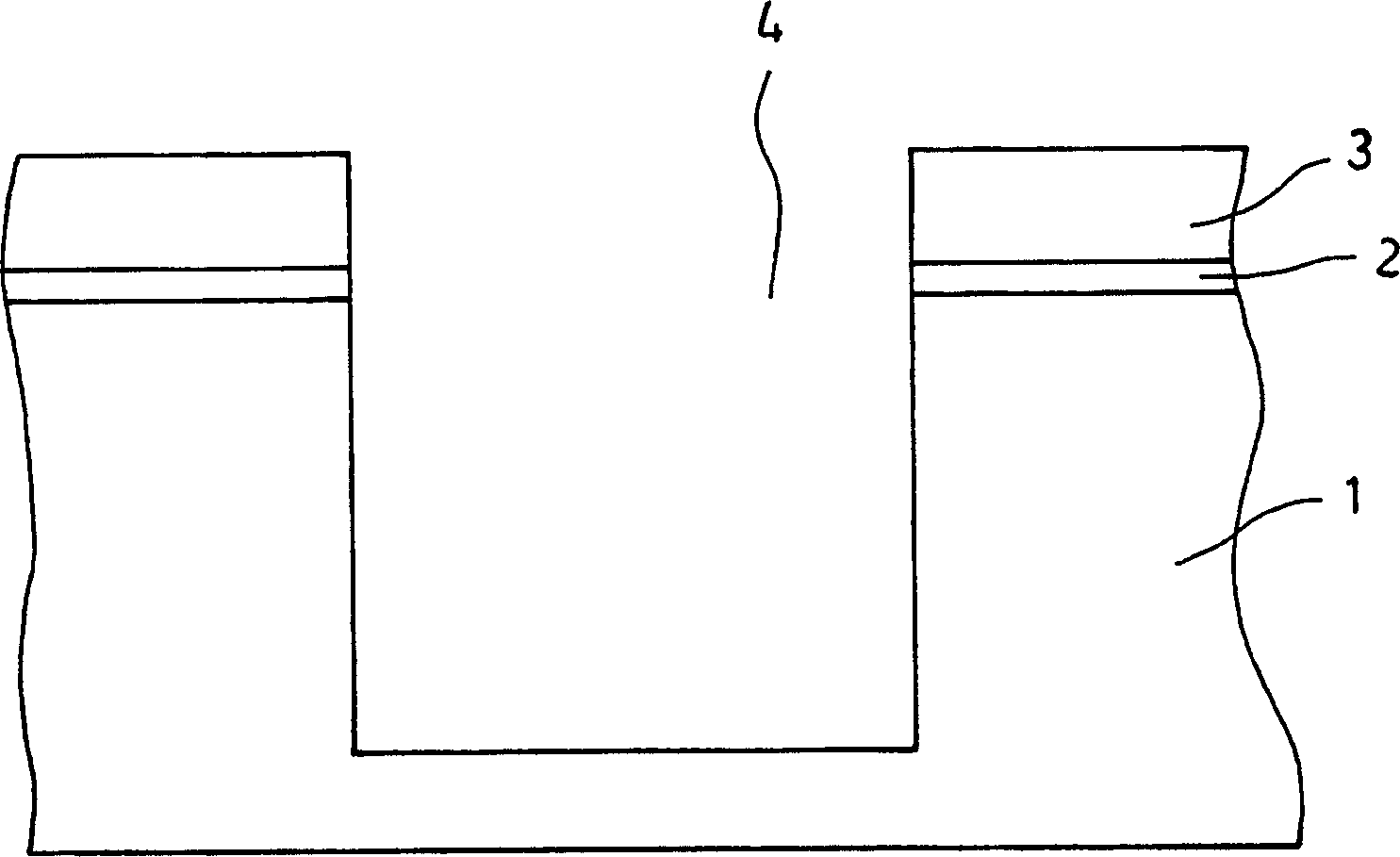

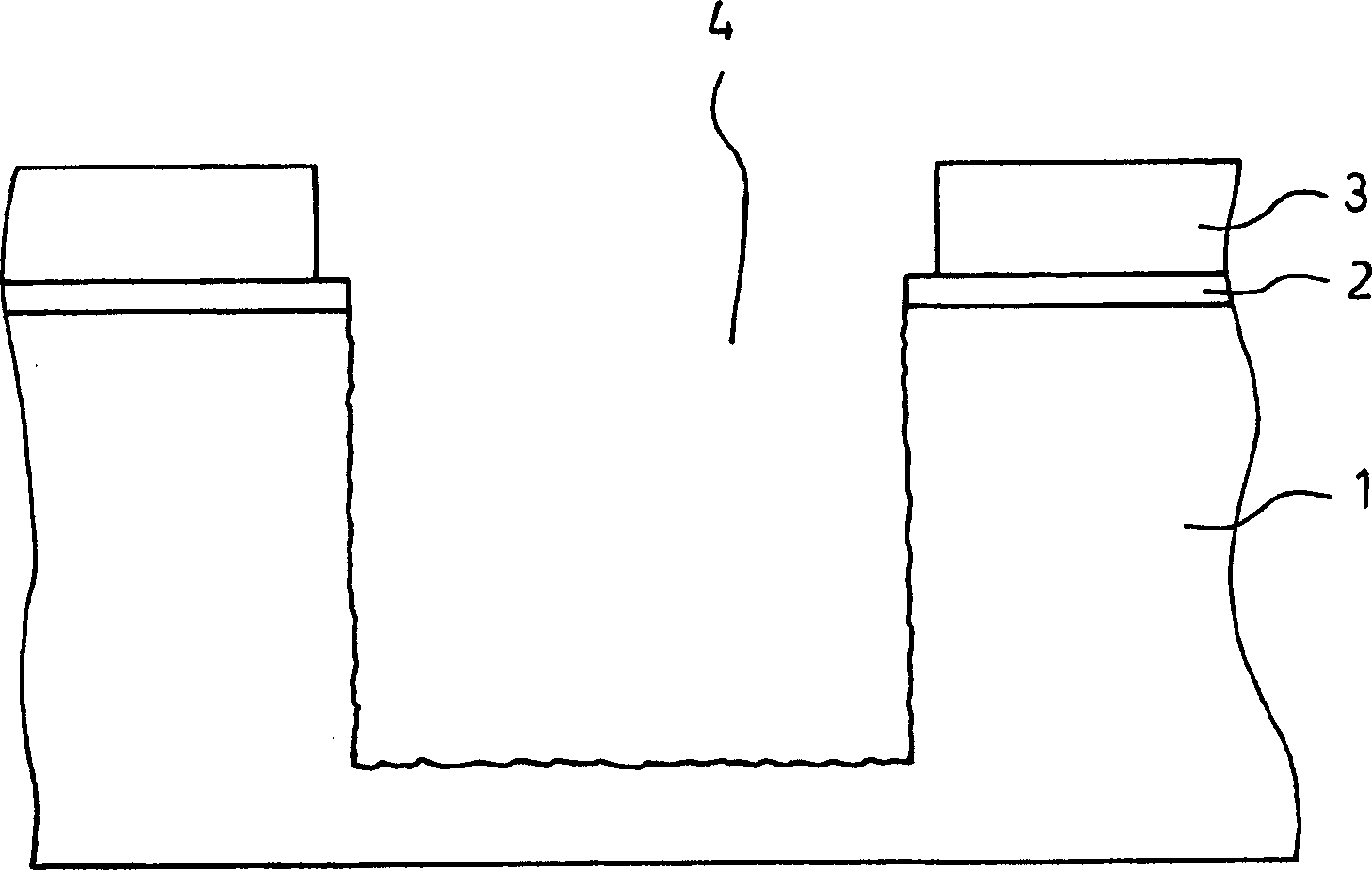

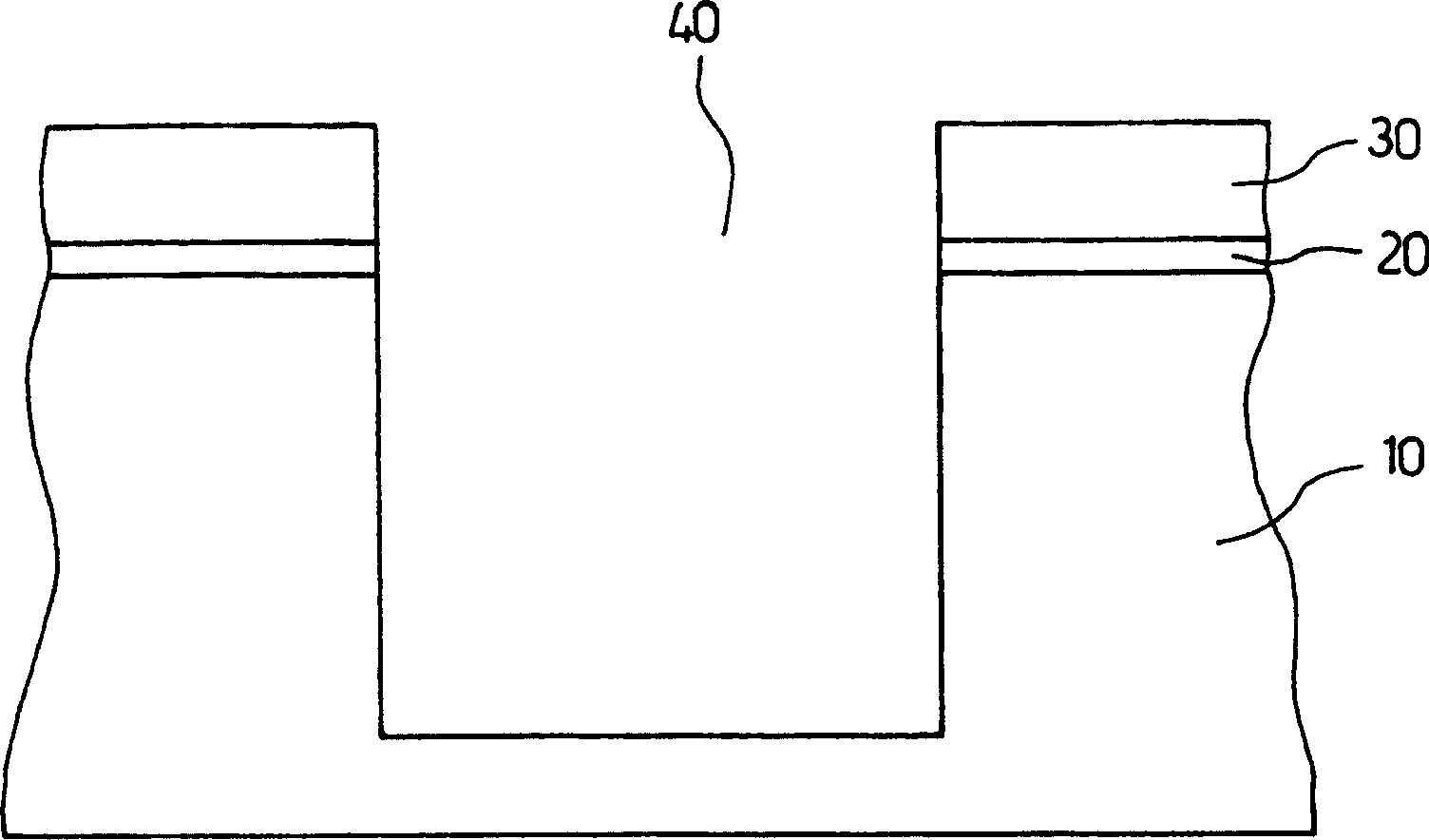

[0026] first reference image 3 , a silicon dioxide layer 20 and a silicon nitride layer 30 are sequentially deposited on the silicon substrate 10 . The thickness of the silicon dioxide layer 30 is about 20 to 60 nm, and it is used to relieve the stress between the silicon substrate 10 and the silicon nitride layer 30 . The thickness of the silicon nitride layer 30 is about 150 to 200 nm, and the pattern on the photomask is transferred through lithography and etching processes, so as to be used as a mask when forming shallow trenches. In addition, the silicon nitride layer 30 can also be used as a stop layer for chemical mechanical polishing (CMP). Then, lithography and etching processes are carried out to form such as figure 1 Shallow trenches 40 are shown.

[0027] After forming the shallow trench 40, the reference Figure 4 , depositing a first pad o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com