Capacitive sensor

A capacitive sensor, sensor technology, applied in the direction of sensor, capacitance measurement, using electric/magnetic device to transfer sensing components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Hereinafter, a first embodiment of the present invention will be described with reference to the drawings.

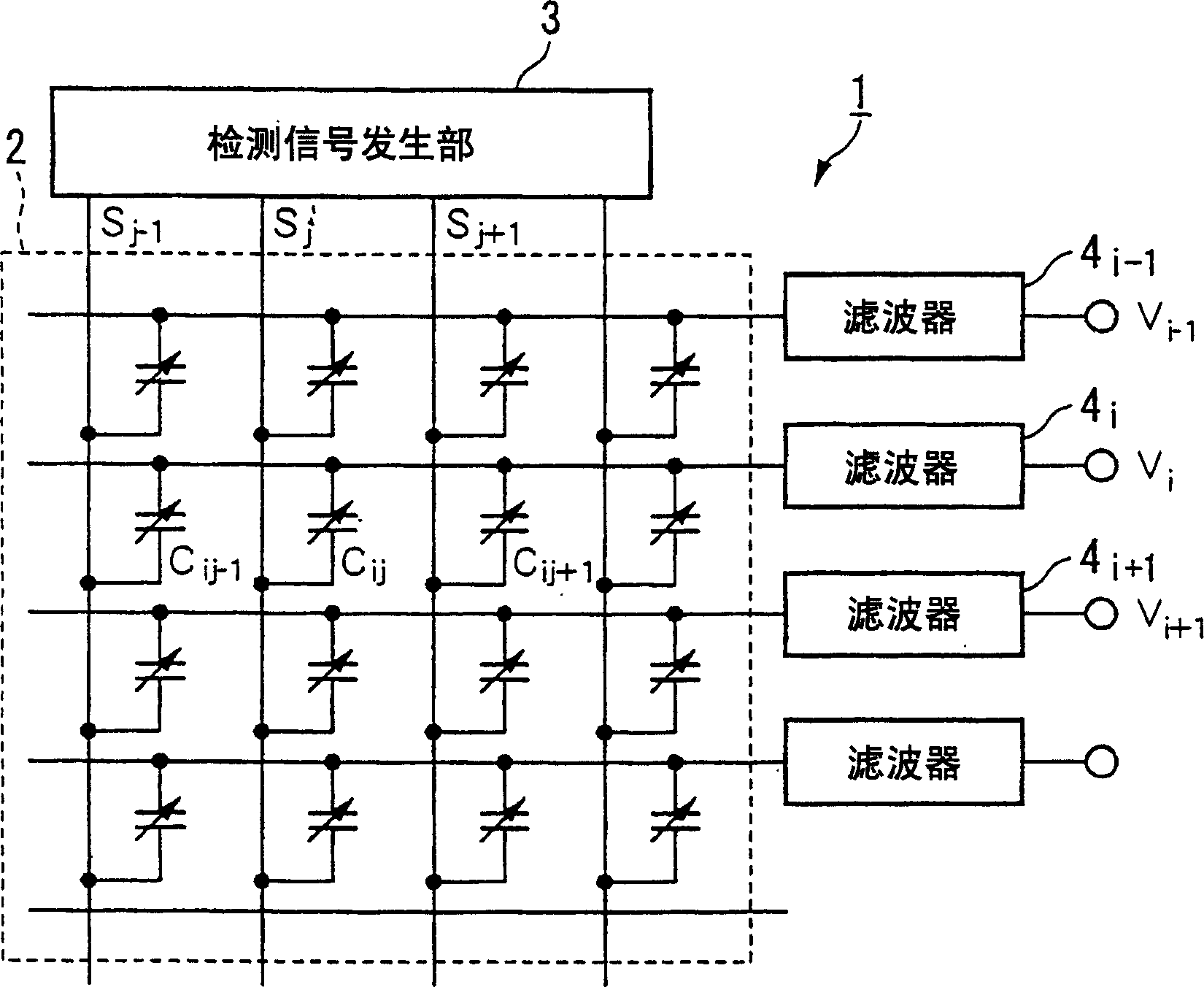

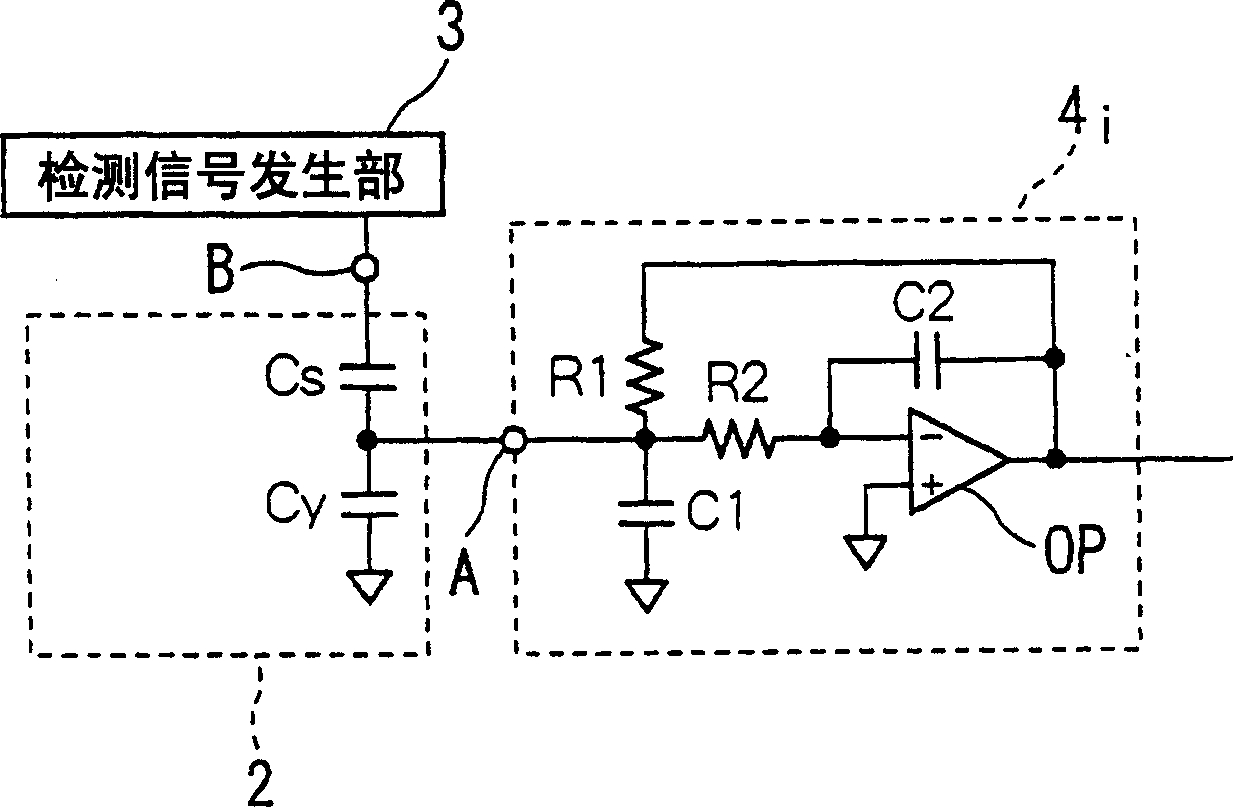

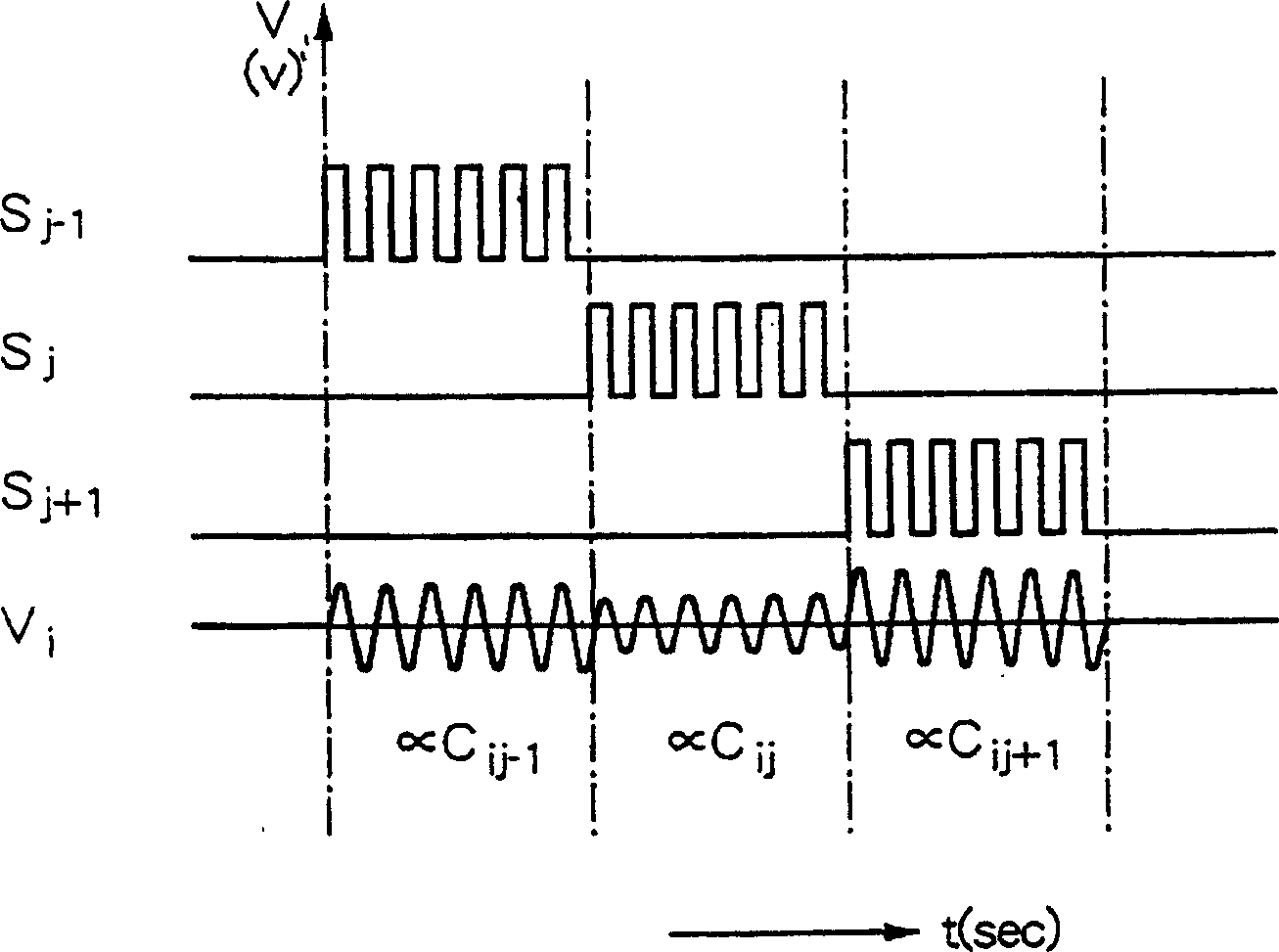

[0035] figure 1It is a block diagram showing the structure of the capacitance sensor 1 of this embodiment. The capacitive sensor 1 shown in this figure is composed of a sensor unit 2 that touches an object to be detected (for example, a finger), a detection signal generation unit 3 that outputs a detection signal to the sensor unit 2, and a filter 4i that receives an output signal from the sensor unit 2. -1, 4i, 4i+1, ... and processing circuits (not shown) for processing the outputs of 4i-1, 4i, 4i+1, ....

[0036] Regarding the sensor part 2, first and second flexible thin plate bodies are arranged at a slight interval, and a plurality of column wirings are formed at equal intervals on the first thin plate body, and a plurality of column wirings are formed on the second thin plate body at equal intervals along the A plurality of row wirings are formed in a d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com