Method for dividing disc-like workpiece

A technology for dividing discs and workpieces, applied in electrical components, manufacturing tools, metal processing, etc., can solve problems such as damaged circuits and low-k film peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The method for cutting a disc-shaped workpiece according to the present invention will be described in detail below with reference to the accompanying drawings.

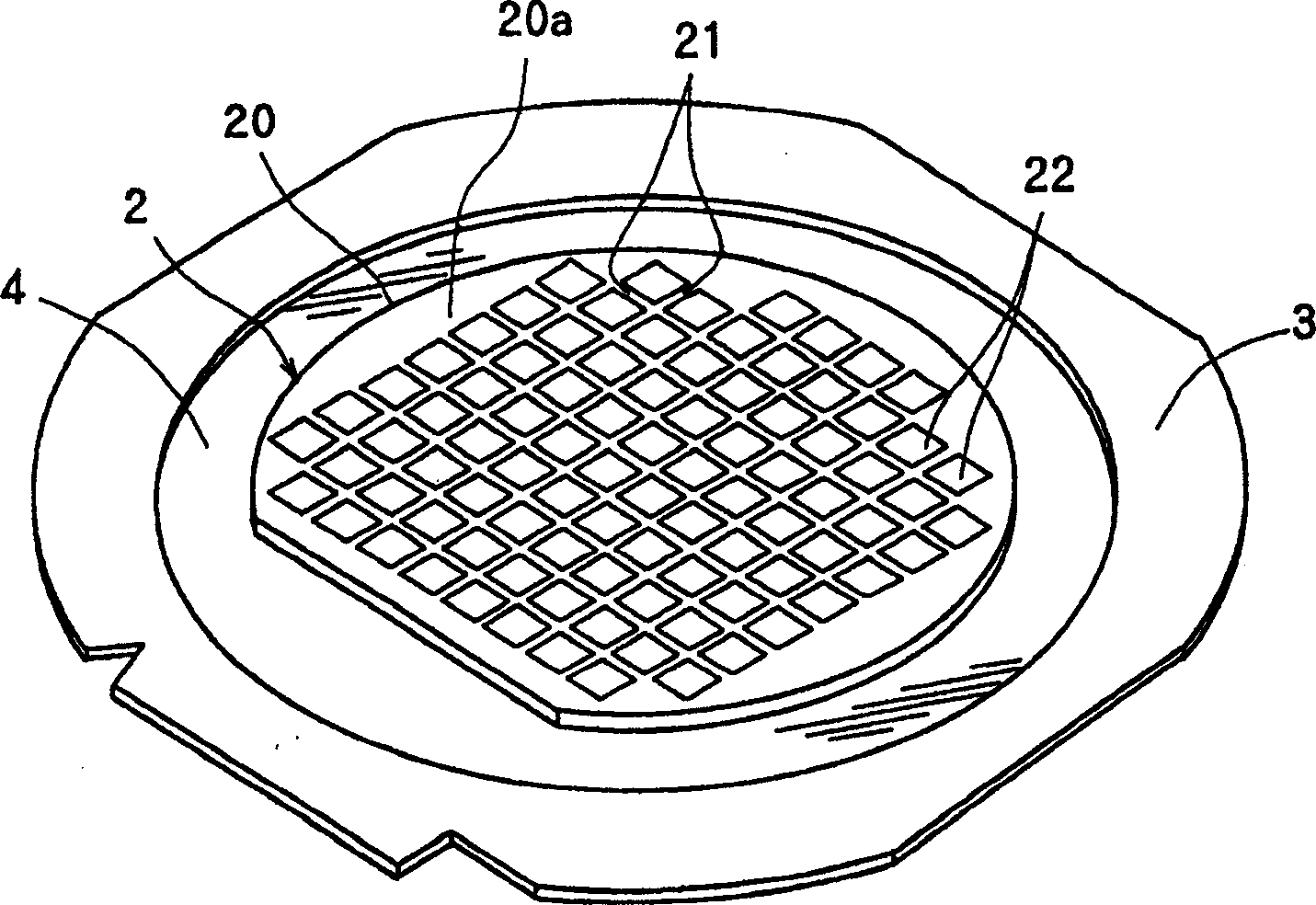

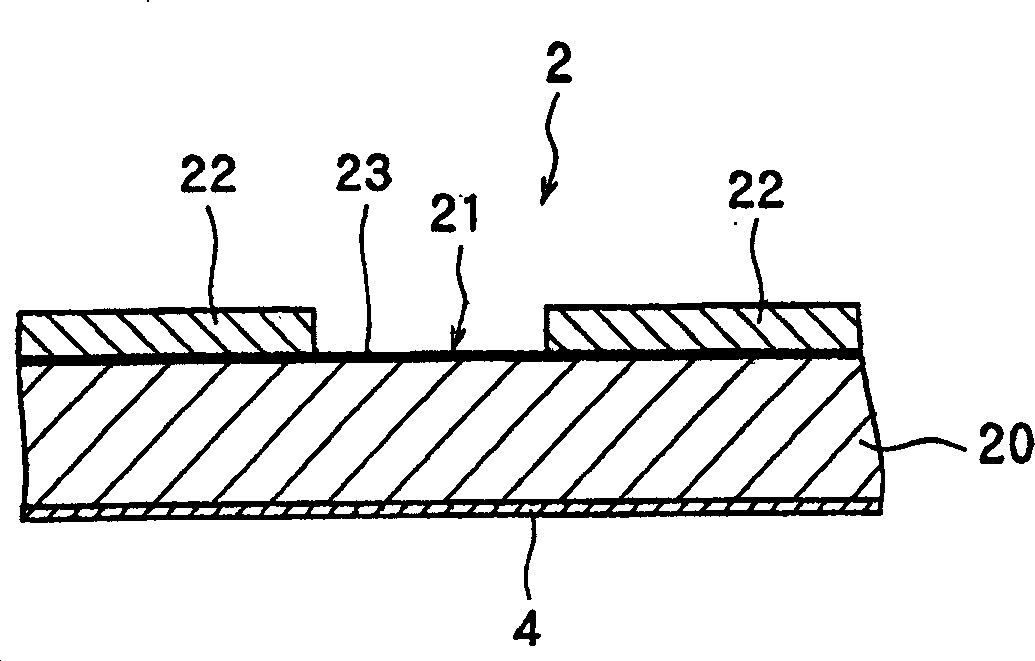

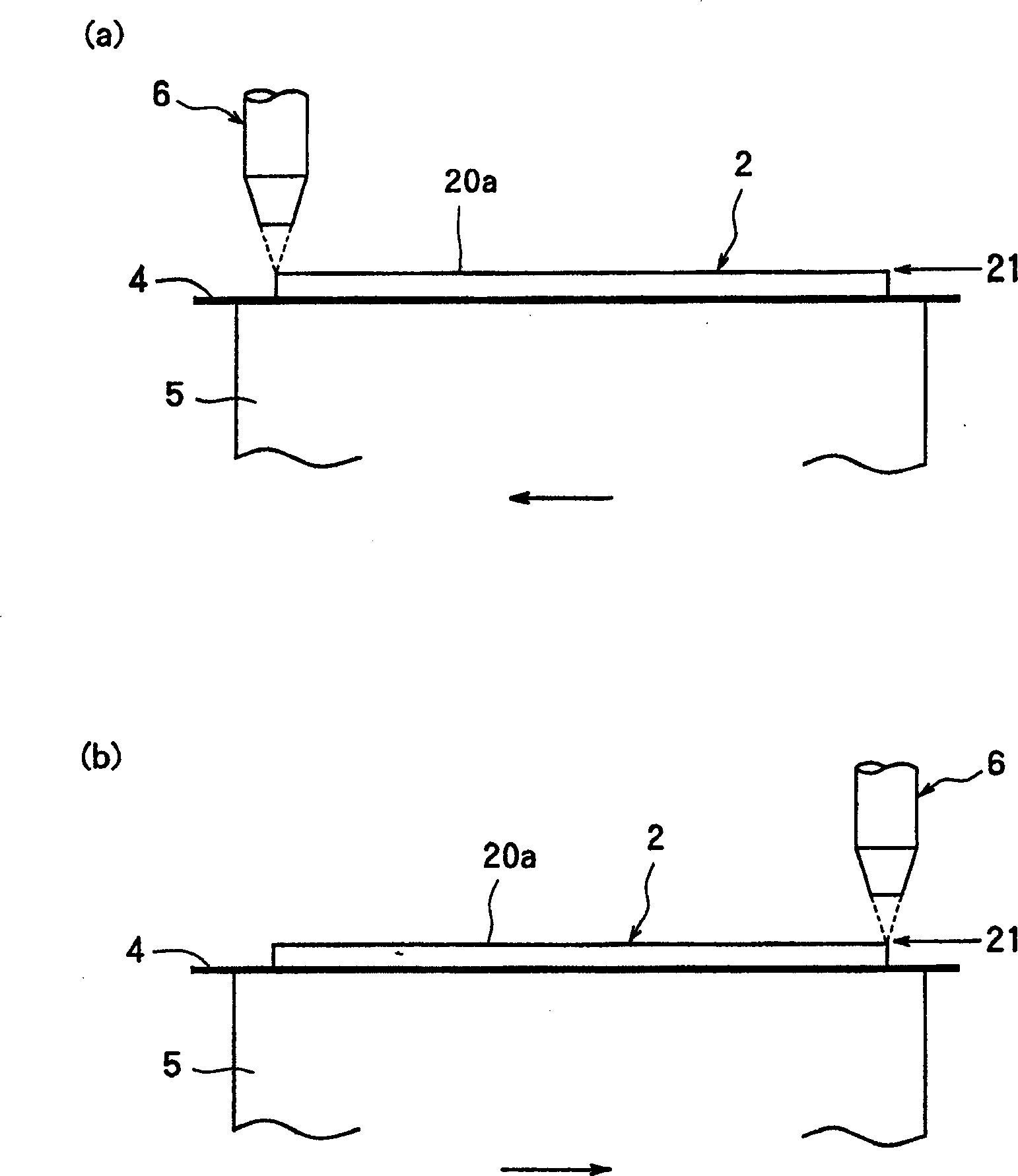

[0023] figure 1 is a perspective view of a semiconductor wafer (as a disk-shaped workpiece) to be divided according to the invention. exist figure 1 In the shown semiconductor wafer 2, a plurality of dividing lines 21 are formed in a lattice pattern on the front surface 20a of a substrate 20 (which is a silicon wafer), and circuits 22 are formed in each of the plurality of regions separated by the plurality of dividing lines 21. formed in. In the illustrated embodiment, as figure 2 As shown, a low-dielectric insulating film (low-k film) 23 composed of an inorganic thin film such as SiOF or BSG (SiOB) and an organic thin film such as a polymer (such as polyimide or parylene) is laminated. On the front side 20 a of the substrate 20 , and the circuit 22 is formed on the front side of the low-k thin film 23 ....

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com