Decelerative clutch for fully-automatic washing machine

A fully automatic washing machine and deceleration clutch technology, which is applied to other washing machines, washing devices, textiles and papermaking, etc., can solve the problems of inconvenient matching with high-speed motors, easy damage of parts, and low reliability, so as to improve transmission efficiency and reliability performance, simplify the structure, and reduce the effect of vibration and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

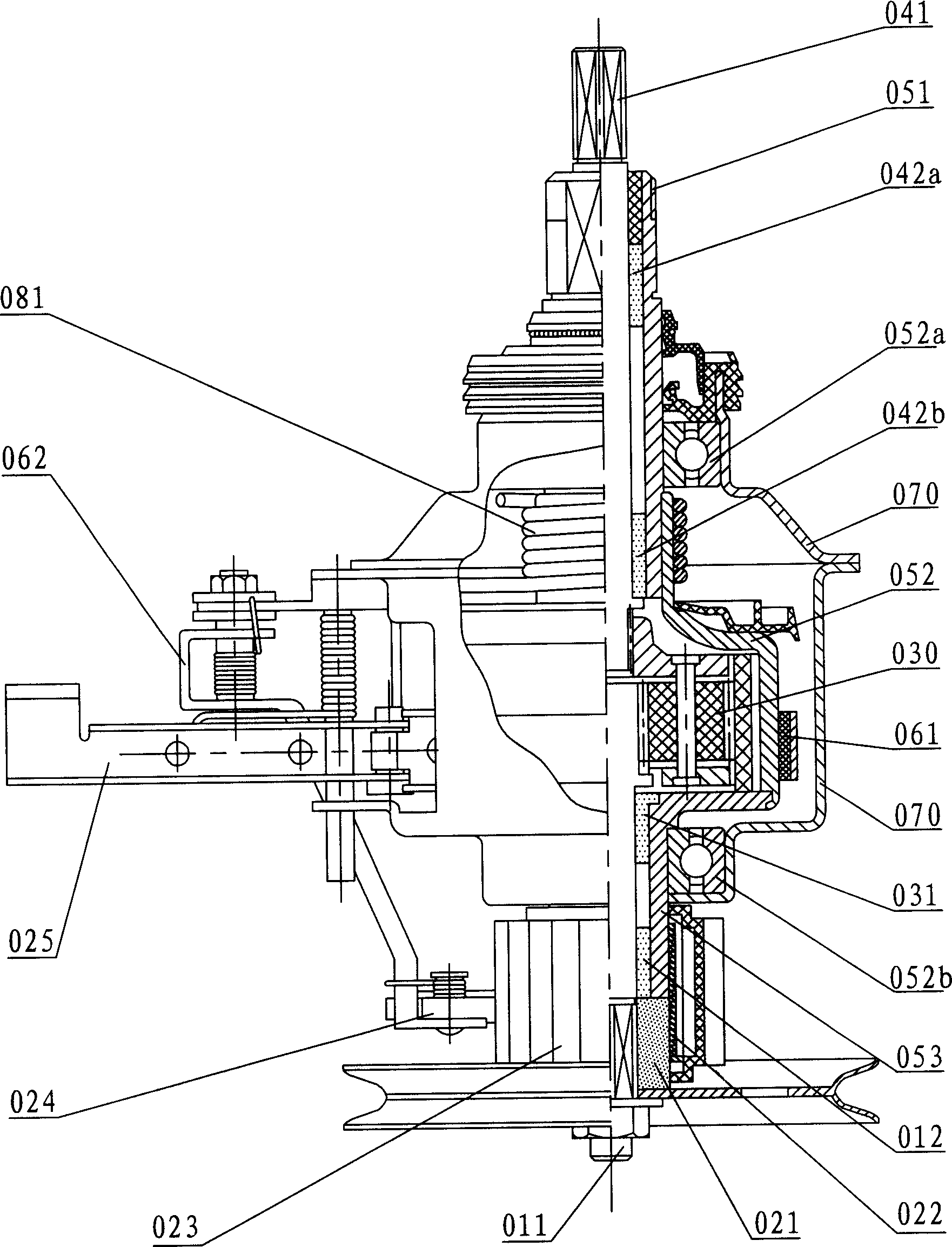

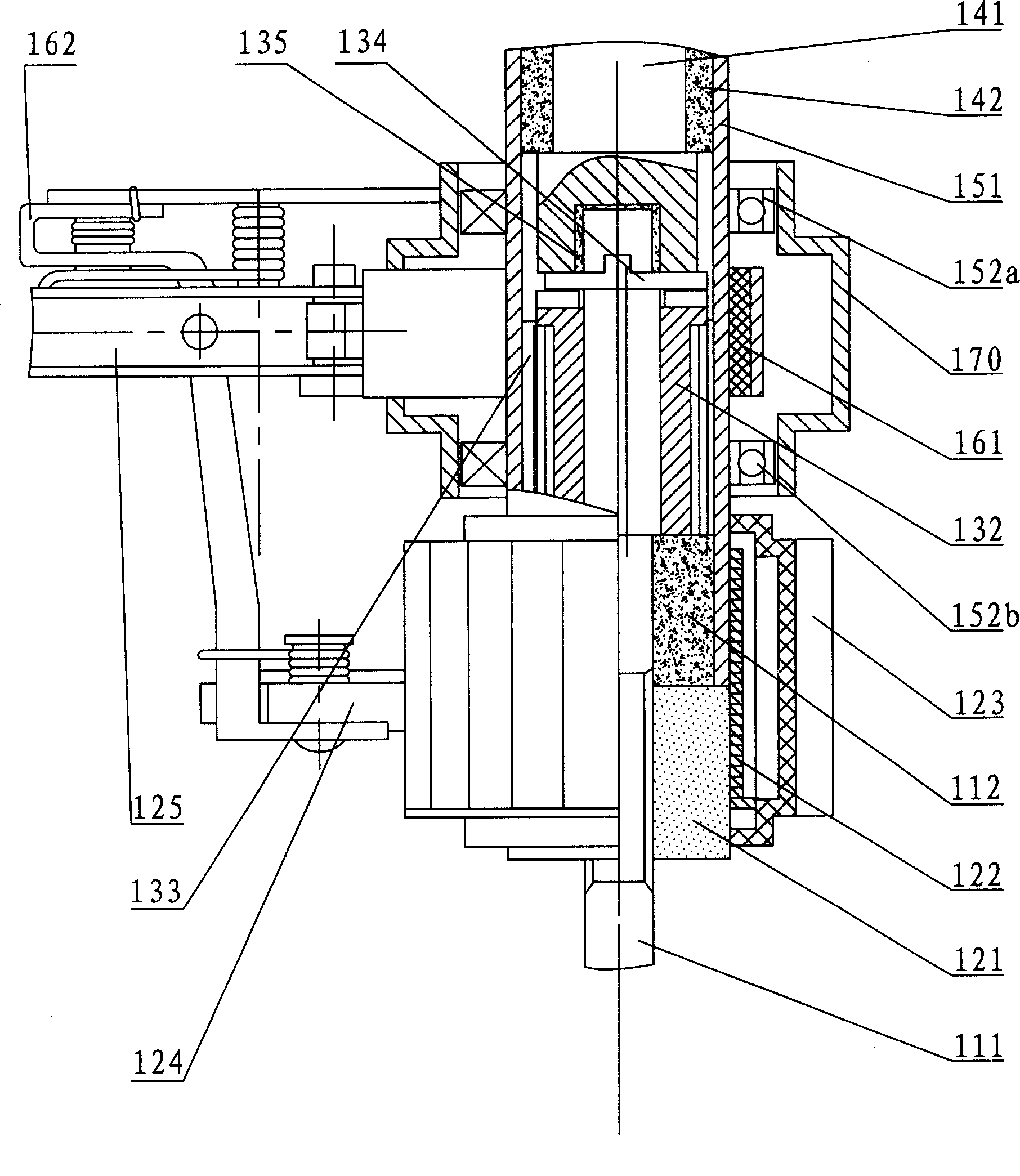

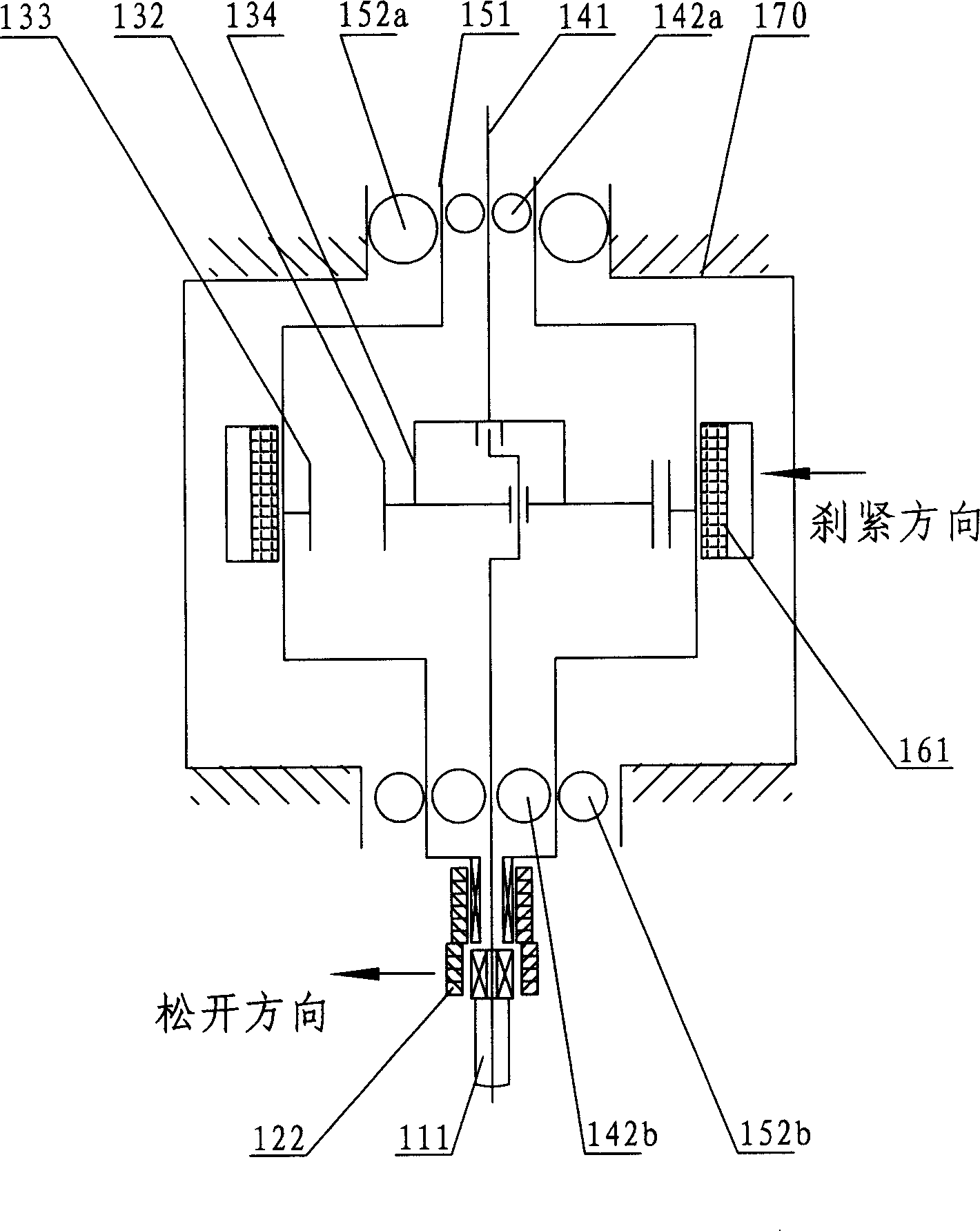

[0036] The first embodiment of the present invention is attached figure 2 , image 3 with Figure 4 Shown. It is introduced in the background technology of this manual as figure 1 The following improvements are mainly made on the basis of the deceleration clutch of the fully automatic washing machine in the prior art shown:

[0037] ——The N-type planetary gear system with small tooth difference is installed in the dehydration shaft 151 to replace the NGW-type planetary gear system in the original brake drum;

[0038] ——The dehydration shaft 151 is a three-in-one combination of the original input sleeve, brake drum and dehydration shaft;

[0039] ——Cancel the non-return spring.

[0040] Therefore, the basic design of the deceleration clutch of this embodiment is as follows:

[0041] The washing shaft 141 is used to contact the stirring wheel of the washing machine and output rotational force to it; the dehydration shaft 151 is used to contact the dehydration barrel of the washing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com