Multicomponent anchoring system optimizing designing method

A technology for optimizing design and mooring systems, applied to ship components, ships, transportation and packaging, etc., to achieve the effects of simple models, easy implementation, and problem-solving interaction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to better understand the technical solutions of the present invention, a further detailed description will be made below in conjunction with the accompanying drawings and embodiments.

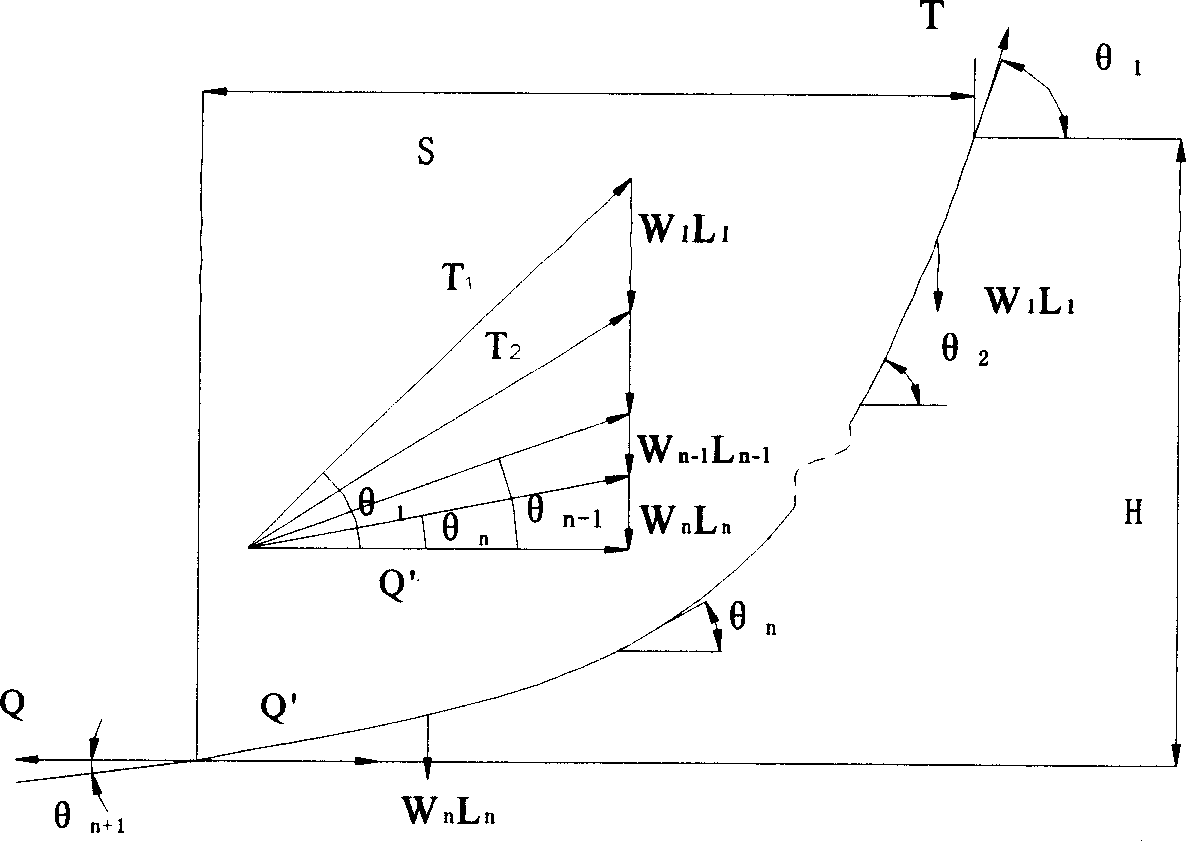

[0020] For a better description, the symbols are specified as follows, which can be referred to image 3 :

[0021] L i , S i 、h i ——line length, horizontal length and vertical length of mooring line of section i (component);

[0022] j——The value ranges from 1 to M, and M is the number of mooring lines of the mooring system;

[0023] i——The value ranges from 1 to N, and N is the number of materials for a single mooring line;

[0024] Q J —horizontal force provided by a single mooring line;

[0025] W k ——the weight per unit length of the inclination angle of the k-th mooring line.

[0026] Step 1: Determine the common characteristics of the materials that make up the mooring line

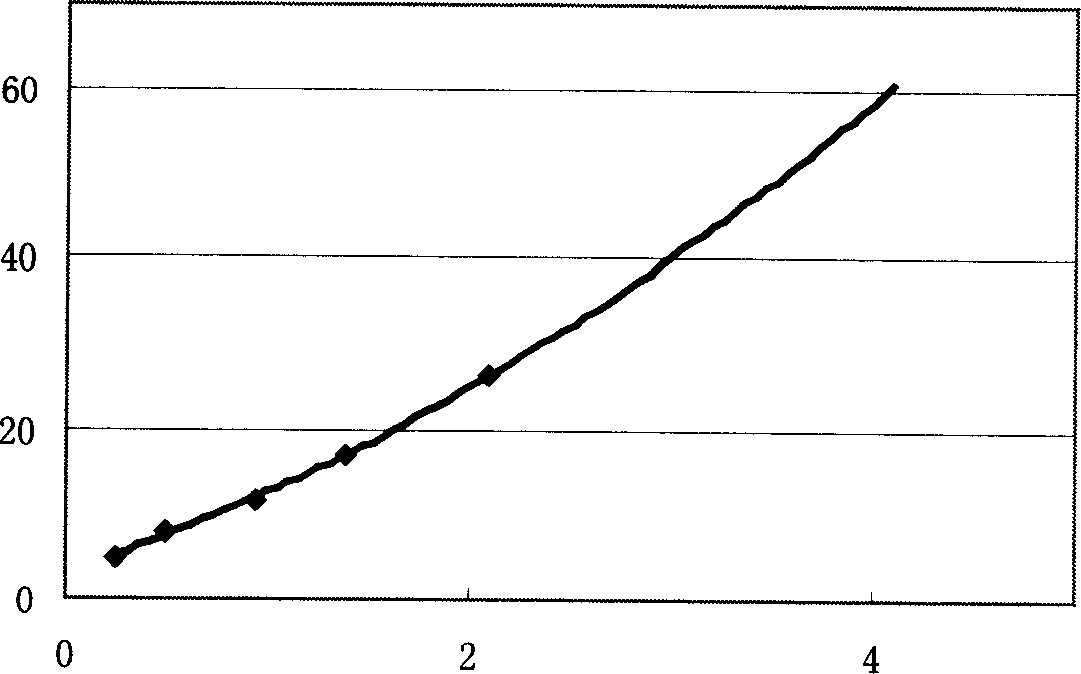

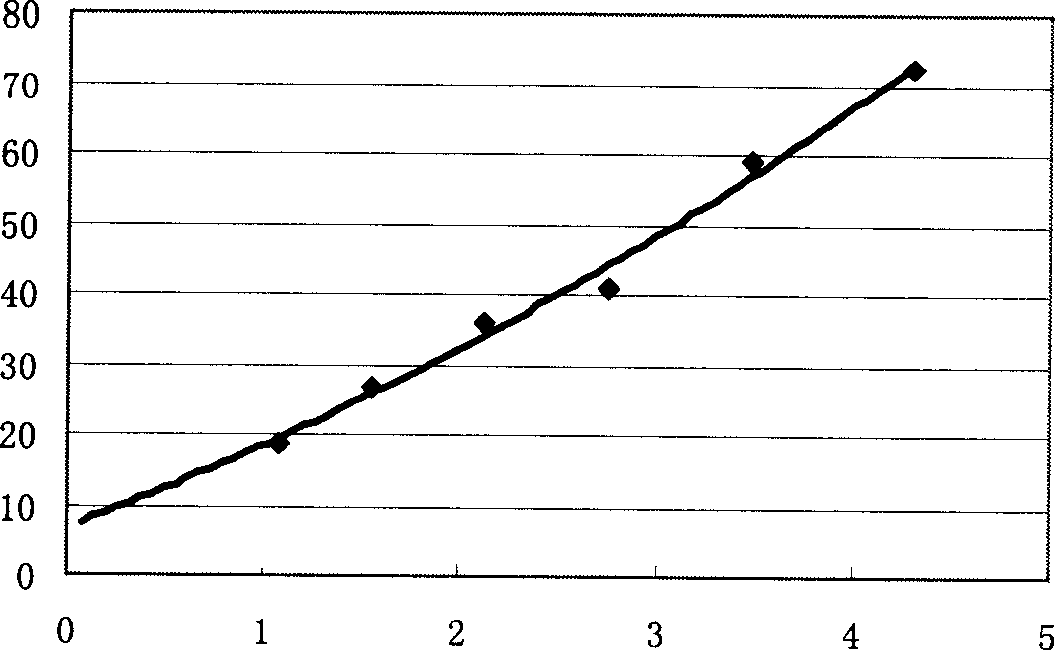

[0027] Determine the quadratic relationship between weight per unit length and breaking...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com