Crystal silver mirror and preparing method thereof

A crystal and silver mirror technology, applied in liquid chemical plating, metal material coating process, coating and other directions, can solve the problems of fading, unevenness, poor brightness and clarity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

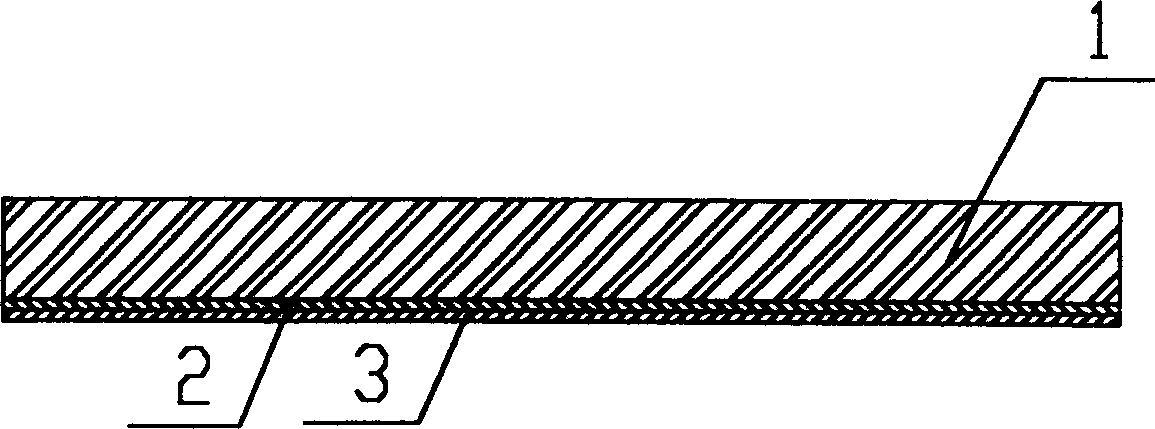

[0008] The present invention adopts the above-mentioned technical scheme, and the crystal plate layer 1 adopts ion-exchanged water to wash the crystal plate and 0.00001-0.4ppm SnCl 2 The solution treats the crystal plate and adjusts the AgNO according to the ambient temperature. 3 , NaOH, and the mixing ratio of ammonia water mixture, so that one surface of the crystal plate layer 1 has a silver-plated layer 2, and the surface of the silver-plated layer 2 has a protective paint layer 3. The thickness of the crystal plate layer 1 is 0.2---100 mm. The mirror surface is made of crystal, which has high brightness and clarity. One surface of the crystal plate layer 1 has a silver-plated layer 2, which makes the crystal silver mirror have high brightness, the silver layer is not easy to fall off, and has a long service life. High, so that the clarity of the mirror surface is high, and at the same time, the surface of the silver-plated layer 2 on the back surface of the mirror surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com