Gear and rack type cooker hood

A technology of rack and pinion and pumping unit, which is applied in the direction of liquid variable displacement machinery, mechanical equipment, machine/engine, etc., which can solve the problems of low mechanical efficiency, high manufacturing cost, and difficulty in adjusting the number of strokes, and achieve the mechanical transmission route Short, easy to manufacture and install, convenient and quick to adjust parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

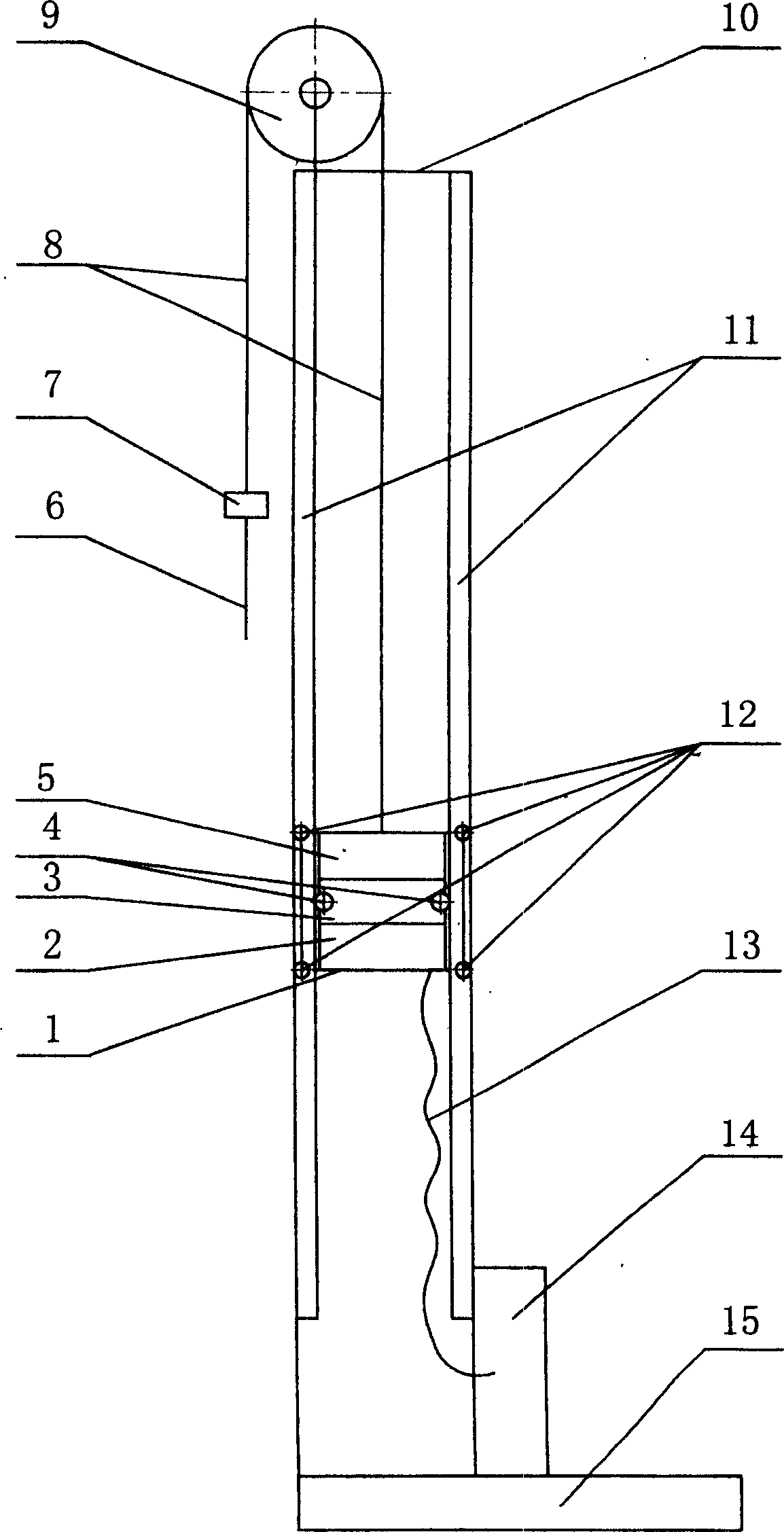

[0014] It can be seen from the figure that a motor 5, a reducer 3, a brake 2 and a guide wheel 12 are installed at the counterweight reciprocating frame 1. The rope hanger 7 is connected with the polished rod 6, the output gear 4 of the reducer 3 is engaged with the rack guide rail 11 installed at the frame 10; the motor 5 is connected with the controller 14 through the accompanying cable 13, and the pulley 9 is installed at the frame 10 . Each part of the counterweight reciprocating frame 1 can be installed separately or partly integrated and integrally installed as a whole reciprocating frame part. The output gear 4 of the reducer 3 meshes with the rack guide rail 11 installed on the frame 10. There are 1 to 2 or more gears. It is 1 to 2 or more, and the tooth shape of the gear and rack is straight, helical or herringbone-shaped switched reluctance motor or DC motor for speed regulation; reducer 3 can use worm gear reducer, gear reducer or planetary cycloid reducer; the br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com