Apparatus and prcoess for filling mercury into fluorescent tubes by circular arranging trolley

A technology of round row cars and fluorescent lamps, which is applied in the manufacture of discharge tubes/lamps, electrical components, cold cathodes, etc. It can solve the problems of mercury waste, pollution, affecting the luminous flux and service life of lamp tubes, etc., and achieve no environmental pollution , the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

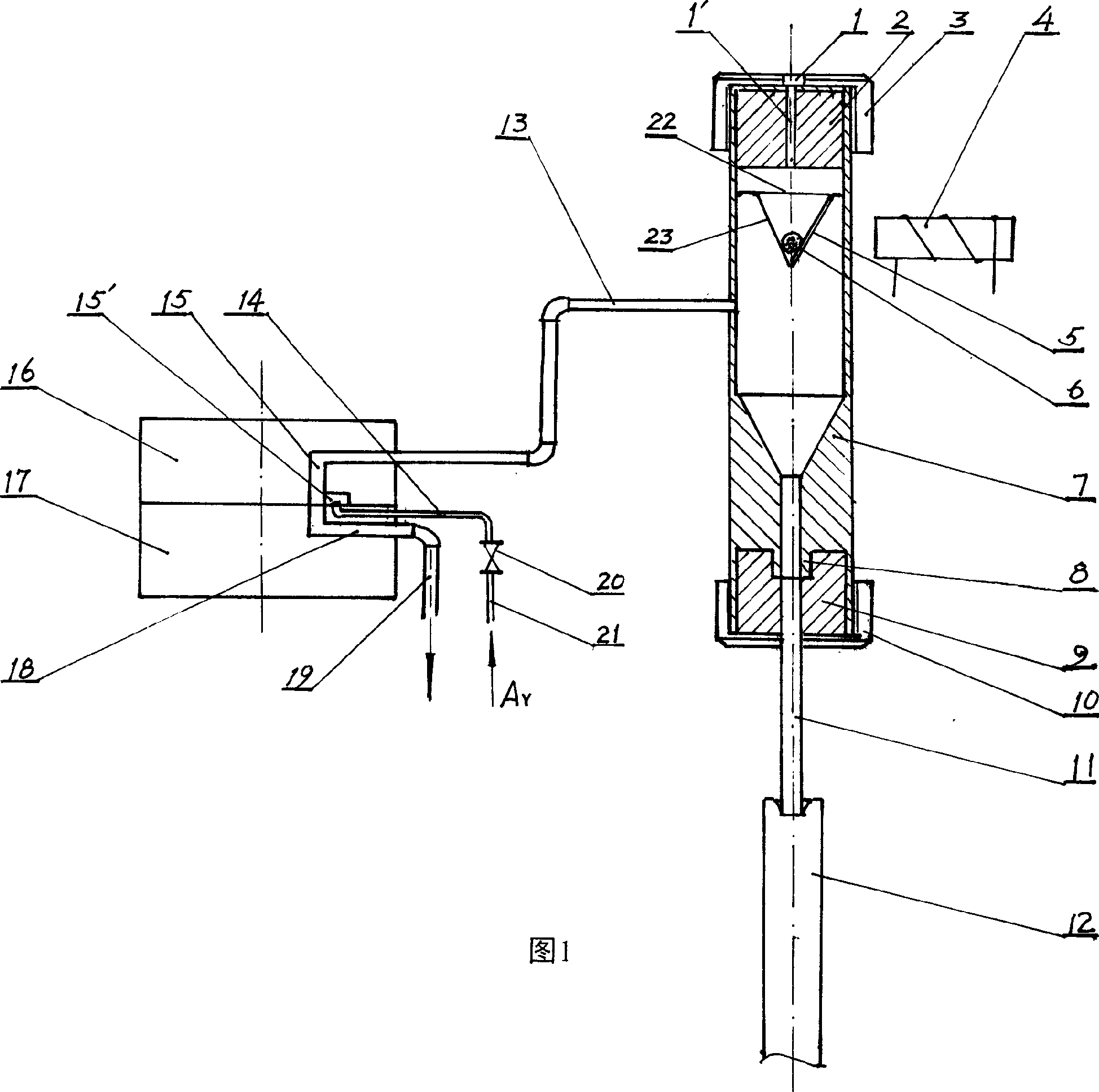

Image

Examples

Embodiment 1

[0020] Vacuum degree: 133.3×10 -2 Pa

[0021] Temperature: 38°C

[0022] Its processing conditions and devices are the same as those described in the specification.

Embodiment 2

[0025] Vacuum degree: 133.3×10 -3 Pa

[0026] Temperature: 30°C

[0027] Its processing conditions and devices are the same as those described in the specification.

Embodiment 3

[0030] Vacuum degree: 133.3×10 -4 Pa

[0031] Temperature: 28°C

[0032] Its processing conditions and devices are the same as those described in the specification.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com