Method for driving LED by current mirror

A technology of light-emitting diodes and current mirrors, applied in the field of current mirror-driven light-emitting diodes, can solve problems such as high power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

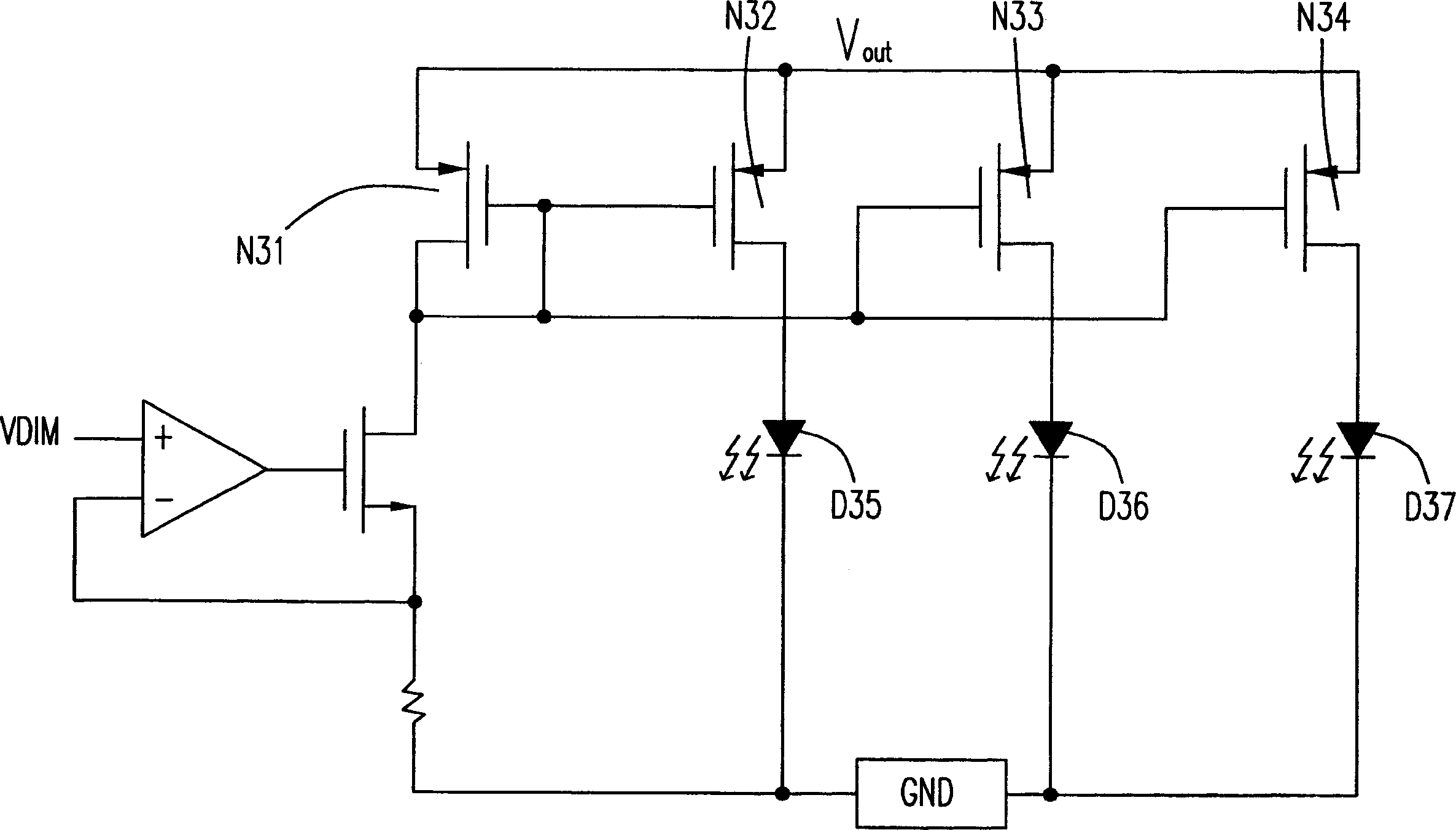

[0034] see Figure 4 , which is a circuit diagram of a preferred implementation of the method for driving a light-emitting diode with a current mirror in the present invention. It uses an inductive boost circuit 40 to boost the voltage at the input terminal of the current mirror 41 to drive the LED coupled to the current mirror 41. A plurality of light-emitting diodes (LEDs) at the output end, as for the color of the light source of the light-emitting diodes, it is not limited to white light, blue light or even light-emitting diodes of other colors can be applied to the method described in the present invention; and for the convenience of explanation and drawing, this The embodiment is only described by using four identical metal-oxide-semiconductor transistors (MOS) current mirrors 41 and three parallel-connected white light emitting diodes. Circuit configuration method of light emitting diode.

[0035] exist Figure 4 Among them, the inductive boost circuit 40 is composed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com