Permanent magnet synchronous motor driving system capable of switching winding

A permanent magnet synchronous motor and drive system technology, applied in the direction of electronic commutation motor control, control system, control generator, etc., can solve the sudden change of output torque, no effective control method for winding switching, dynamic speed control system Performance impact and other issues, to achieve the effect of less reactive power, improve operating efficiency and fault tolerance, and improve reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

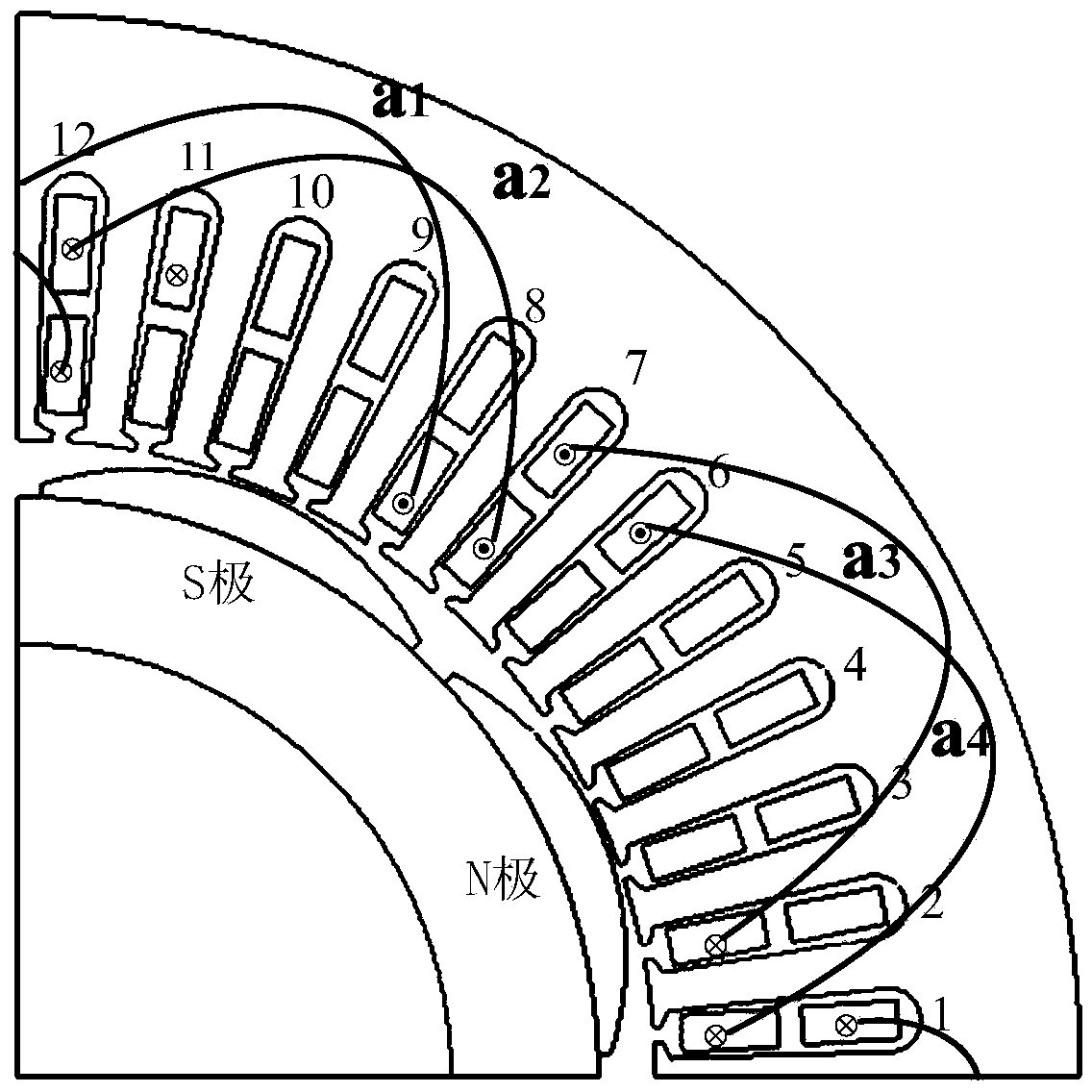

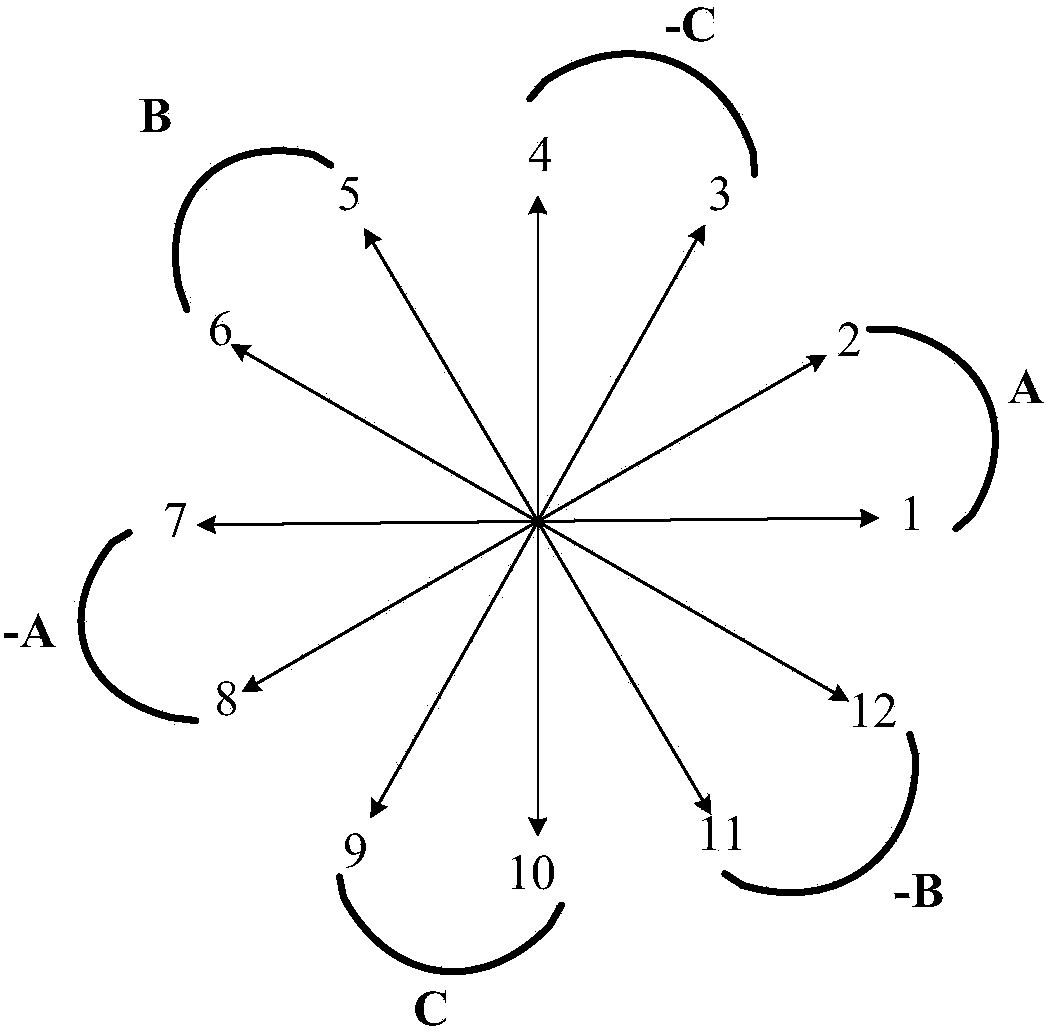

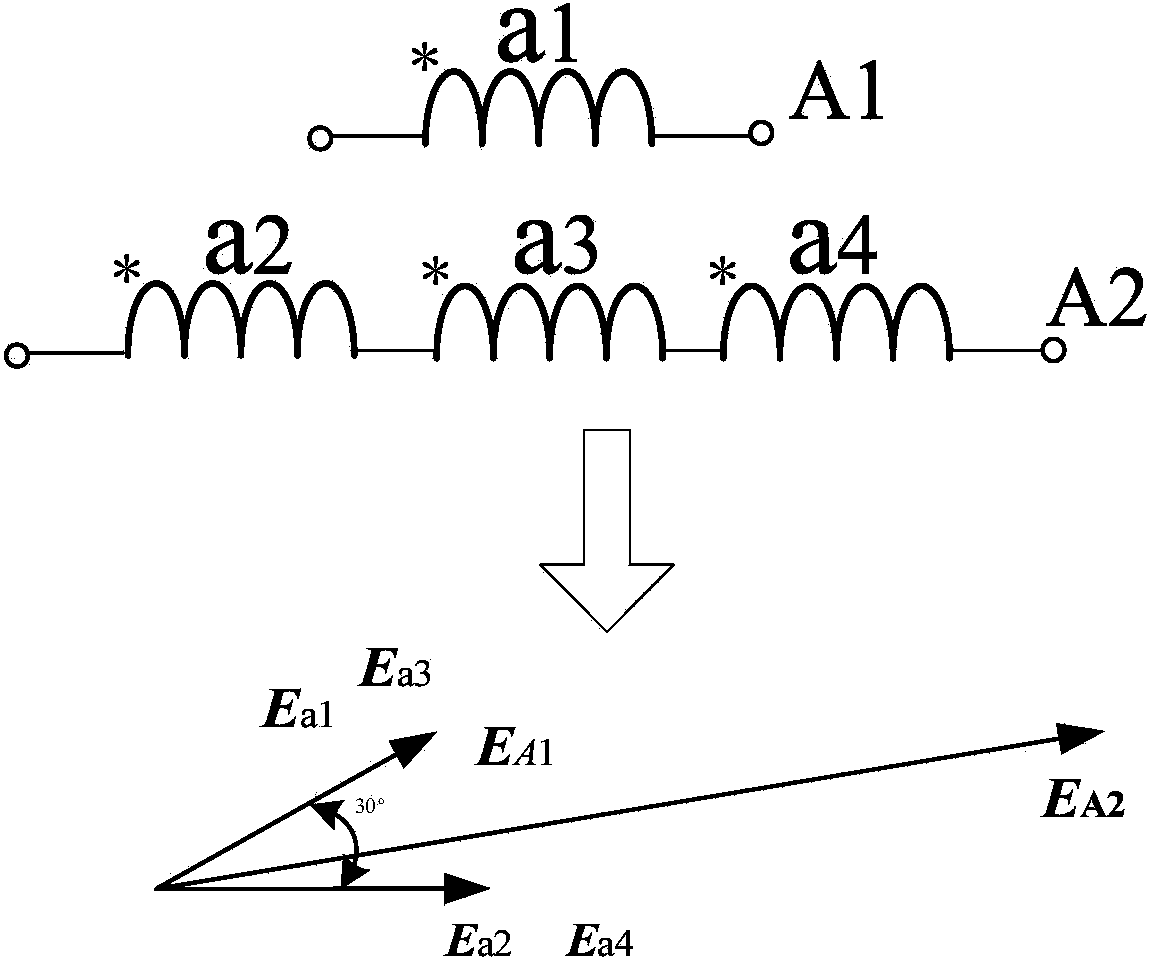

[0040] Figure 2(a) A structure of the permanent magnet synchronous motor drive system with switchable windings of the present invention is shown. As shown in the figure, the permanent magnet synchronous motor drive system includes: a permanent magnet synchronous motor with the stator three-phase armature winding ends opened, an inverter Transformer 1, inverter 2, winding switch conversion device and system controller. Among them, the stator three-phase armature winding of the permanent magnet synchronous motor is divided into a set of three-phase winding 1 composed of windings A1, B1, and C1, and a set of three-phase windings composed of windings A2, B2, and C2 by using the above-mentioned method of winding splitting, combination and reconstruction. A set of three-phase windings 2; the ends of the windings A1, B1, and C1 are respectively connected to the three-phase output ends of the inverter 1, and the ends of the windings A2, B2, and C2 are respectively connected to the th...

Embodiment 2

[0046] Figure 2(b) Another structure of the permanent magnet synchronous motor drive system with switchable windings of the present invention is shown. The difference from the structure of Embodiment 1 is that the inverter 1 and the inverter 2 are respectively powered by two DC power supplies Udc1, Udc2 Independent power supply.

Embodiment 3

[0048] Figure 2(c) Another structure of the permanent magnet synchronous motor drive system with switchable windings of the present invention is shown. As shown in the figure, the winding switch conversion device in this embodiment includes three thyristors connected end to end to form a delta connection; The three connection points between them are respectively connected to the three intermediate taps, and the gates of the three thyristors are respectively connected to the system controller signal.

[0049]Its working principle and process are similar to the winding switching converter device in Embodiment 1. When the winding switching needs to be realized, the system controller gives a control signal to the gates of the three thyristors at the same time to control the opening of the three thyristors. and shutdown. When all three thyristors are turned on, such as Figure 2(c) As shown, the three middle taps of the three-phase winding of the permanent magnet synchronous mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com