Multiple wind wheel strong generator

A technology of powerful generators and multiple wind turbines, applied in wind turbines, wind turbine combinations, wind energy power generation, etc., can solve the problems of too large difference in linear speed, reducing the rotational torque of wind energy impellers, and not improving wind power efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

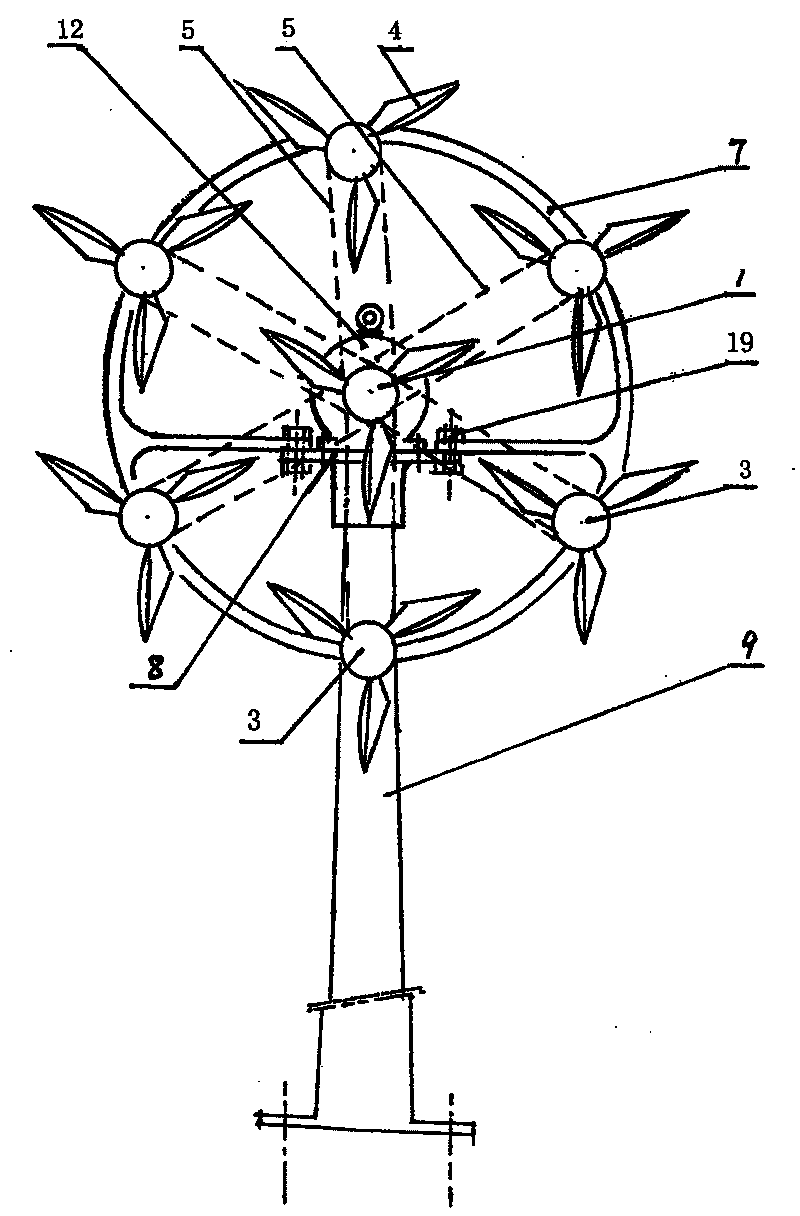

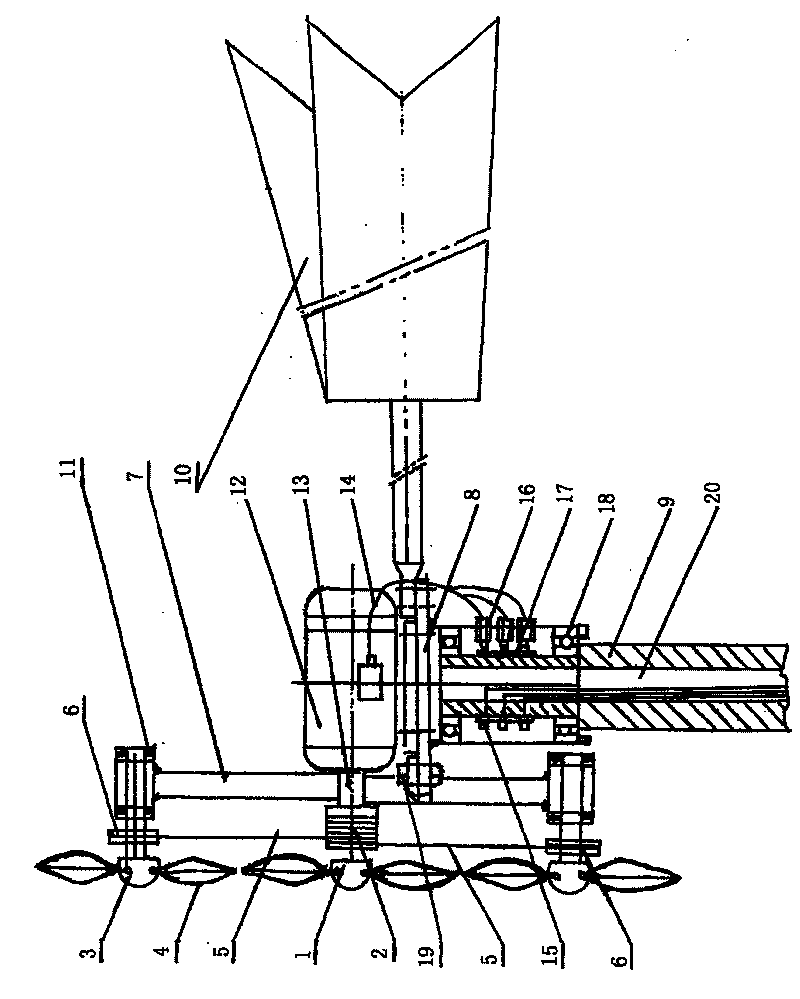

[0029] The above-mentioned auxiliary wind wheel 3 is 6, and the bearing assemblies 11 on the main frame 7 are 6, and they are arranged in a circle. When the connecting wheel 2 on the generator shaft 13 is a multi-groove wheel, the auxiliary wind wheel connecting wheel 6 passes through The belt is connected with it, and when the connecting wheel 2 is a multi-sprocket, the corresponding auxiliary wind wheel connecting wheel 6 is also connected by a chain. There are 3 wind blades.

Embodiment 2

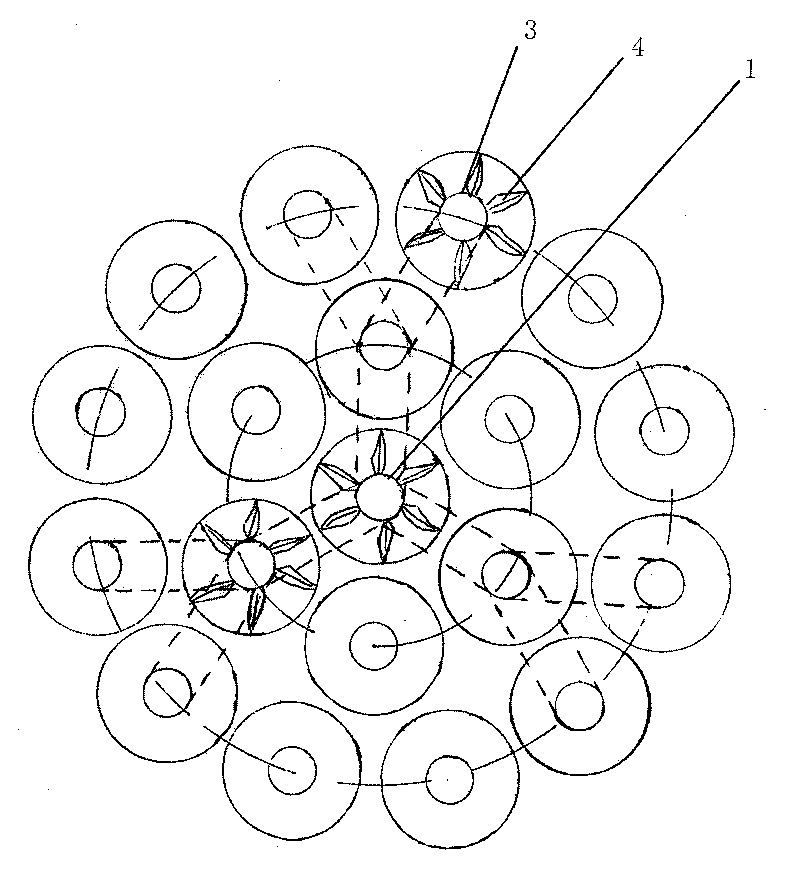

[0031] When there are 18 auxiliary wind wheels 3, there are 18 bearing assemblies 11 on the main frame 7, and they are arranged in a circle. Every two auxiliary wind wheels 3 on the outermost layer are connected in parallel with the middle auxiliary wind wheel 3 , and the middle auxiliary wind wheel 3 is then connected to the main wind wheel 1 . There are 6 wind blades.

Embodiment 3

[0033] When there are 27 auxiliary wind wheels 3, there are 27 bearing assemblies 11 on the main frame 7 arranged in a triangle. The outermost auxiliary wind rotor 3 is connected in series and parallel to the middle auxiliary wind rotor 3 , and then connected to the main wind rotor 1 . There are 3 wind blades.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com