Direct current power ergometer and its control system

A technology of electric dynamometer and DC motor, which is applied in the direction of power metering, measuring devices, instruments, etc., and can solve the problems of more fatal impact on measurement accuracy, waste, and impact on measurement accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

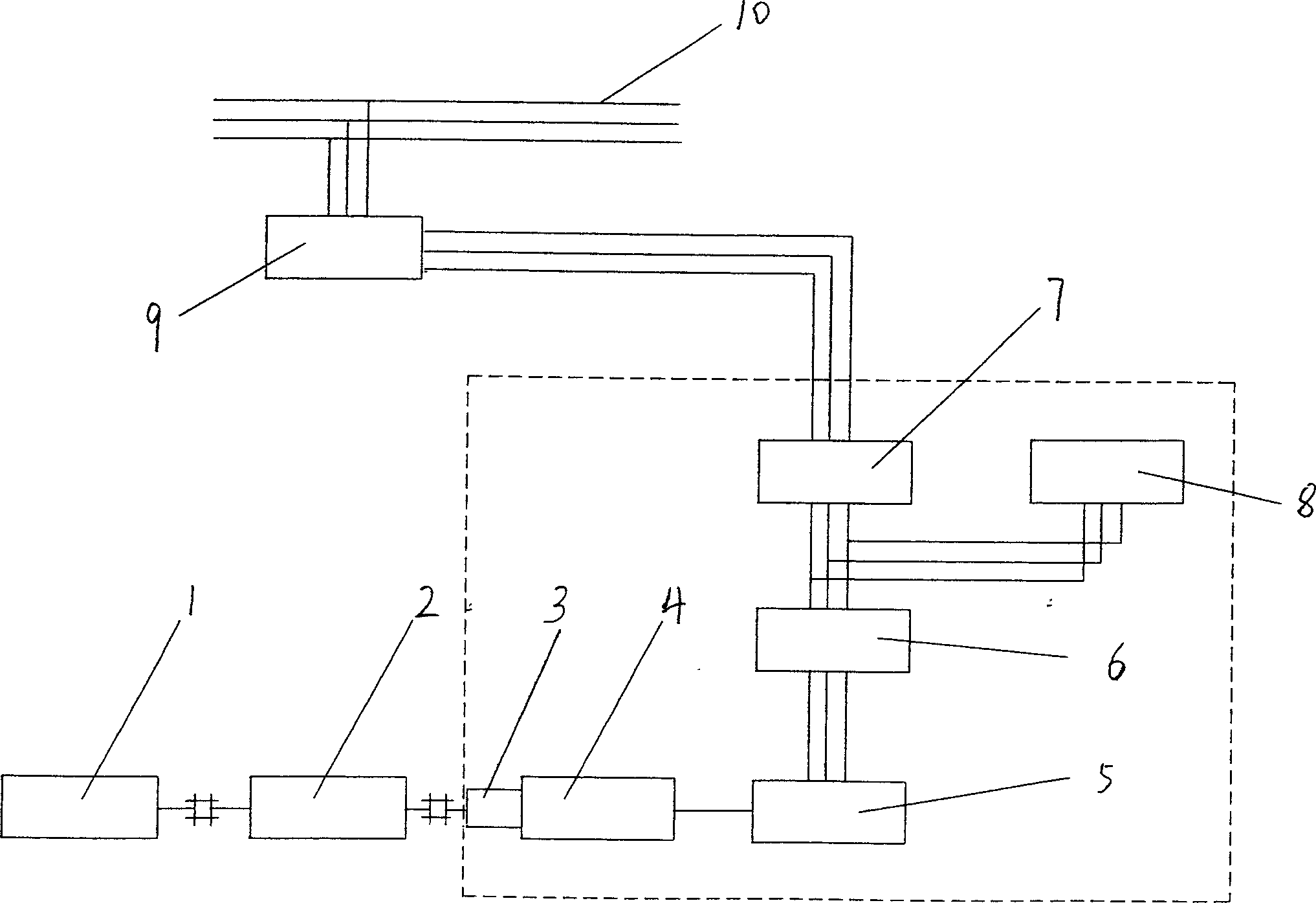

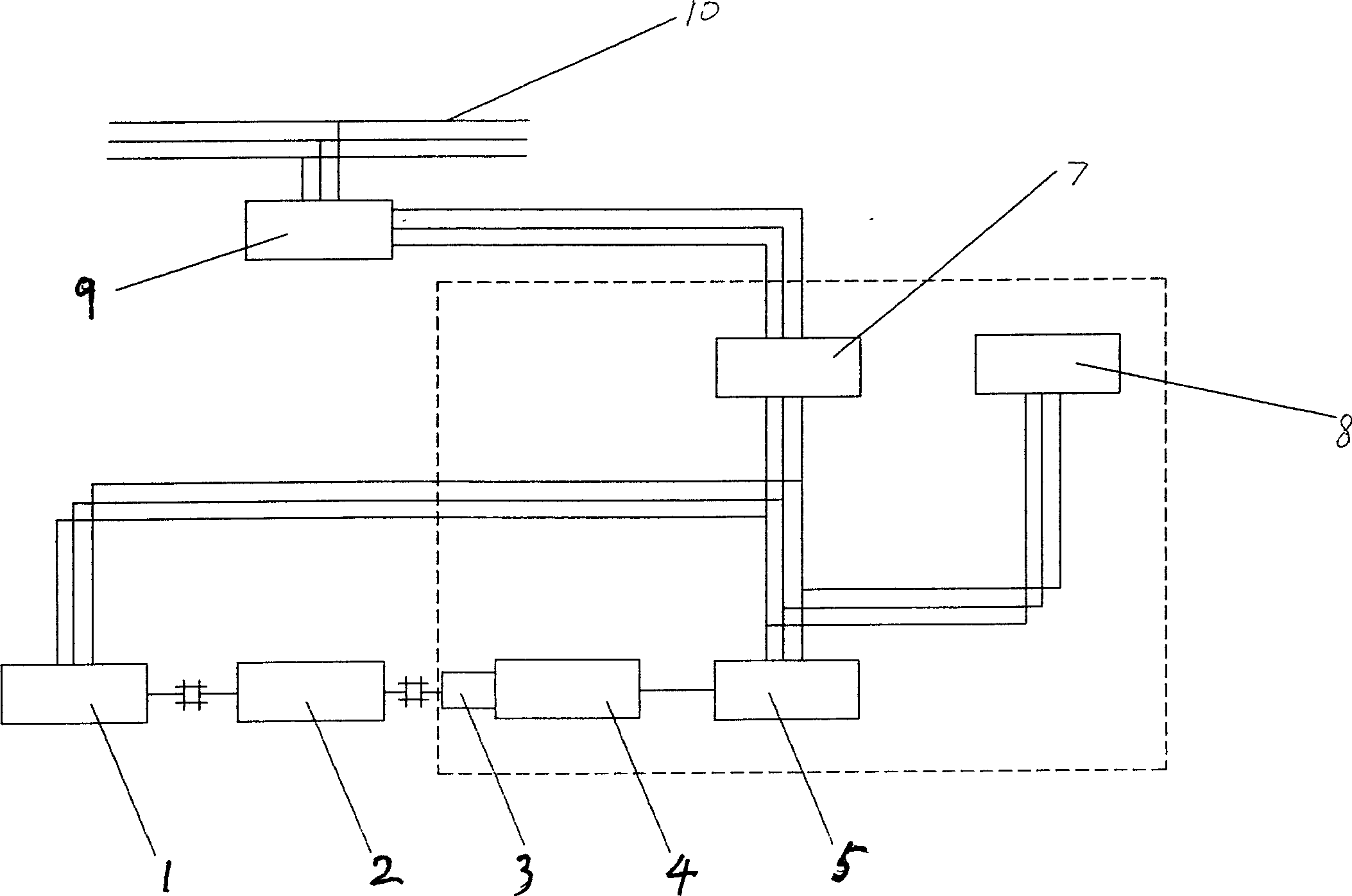

[0005] according to Figure one As shown, the mechanical power transferred from the prime mover 1 through an intermediate device (such as a gearbox) 2 is measured by a bearingless torque sensor 3 and directly converted into a DC power by the dynamometer host 4 (DC motor or DC generator), and then The four-quadrant DC motor drive control cabinet 5 is converted into three-phase AC power matching the power supply parameters of the grid by active inverter mode, and then sent to the output side of the power distribution cabinet 7 after passing through the high-order harmonic isolation transformer 6. The invention also needs to connect the reactive power compensation cabinet at the output side of the power distribution cabinet 7 in parallel. The three-phase alternating current power is sent to the power distribution cabinet 7 through the isolation transformer 6 to eliminate high-order harmonics. Such electric power can be fed back to the power grid or sent to the prime mover for reuse, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com