Monitoring method and device for laser phase Doppler powder dust particle

A Doppler dust and particle monitoring technology, which is applied in measuring devices, color/spectral characteristic measurement, particle size analysis, etc., can solve problems such as small measurement range, low instrument sensitivity, beam spot expansion measurement error, etc., and achieve measurement accuracy and The effect of high spatial resolution, high measurement accuracy and wide measurement range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with the discharge dust monitoring to certain coal-fired boiler, the implementation process of the present invention is described in detail:

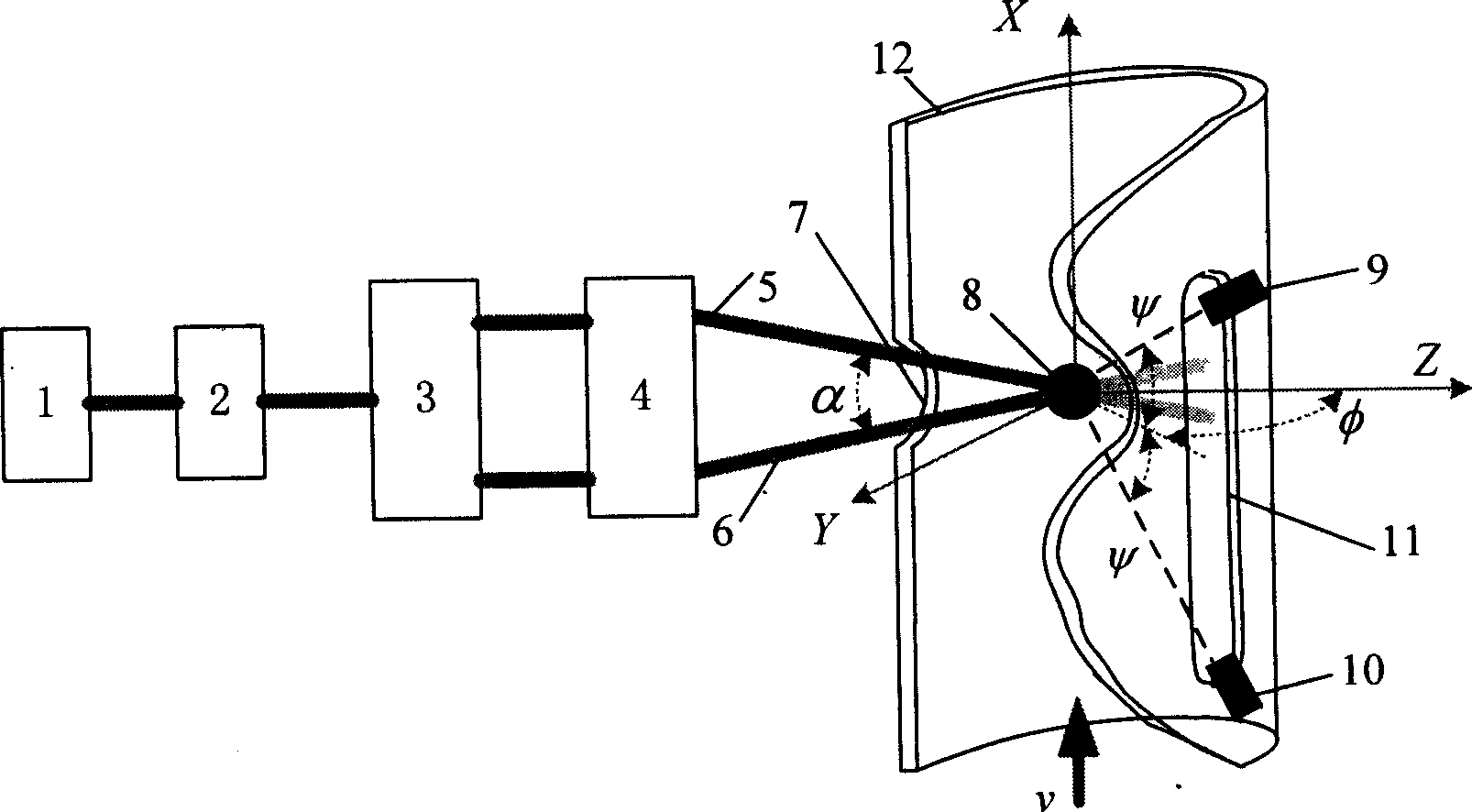

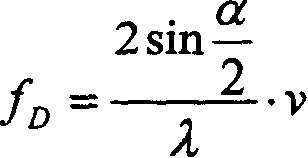

[0017] During the monitoring process of the dust discharge of a coal-fired boiler, the optical detection system of the device of the present invention is installed on the boiler dust discharge channel 12 (as attached figure 2 As shown), the diameter of the channel is 800mm, a round hole 7 is opened on the incident light side, and a long hole 11 is opened on the side receiving the scattered light. Both holes are inlaid with transparent materials. The single-frequency laser output by the laser 1 is converted into two coherent beams with equal intensity by the polarizer 2 and the beam splitter 3. After being focused by the objective lens 4, the two coherent incident beams 5 and 6 are converged at the discharge dust particle flow 8 at an angle α .

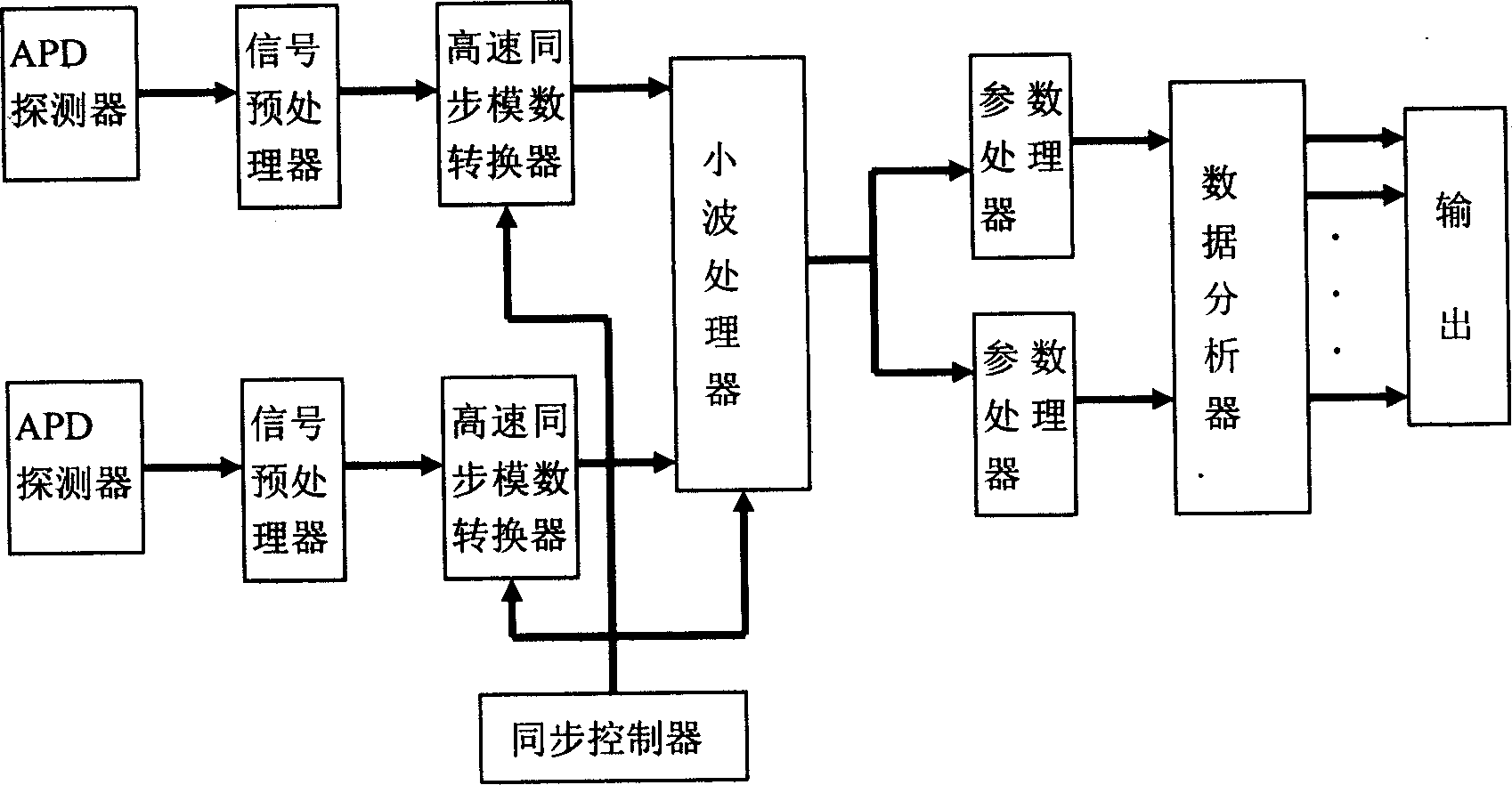

[0018] The two APD detectors 9 and 10 receive scattered light ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com