Three phase AC motor with less wave form distortion ratio and high efficiency

A technology of three-phase AC and waveform distortion, applied in asynchronous induction motors, synchronous machines, electrical components, etc., can solve the problems of high voltage waveform distortion rate, increase motor vibration, internal consumption, and high weight, and achieve voltage waveform distortion rate The effect of reducing and reducing motor vibration and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

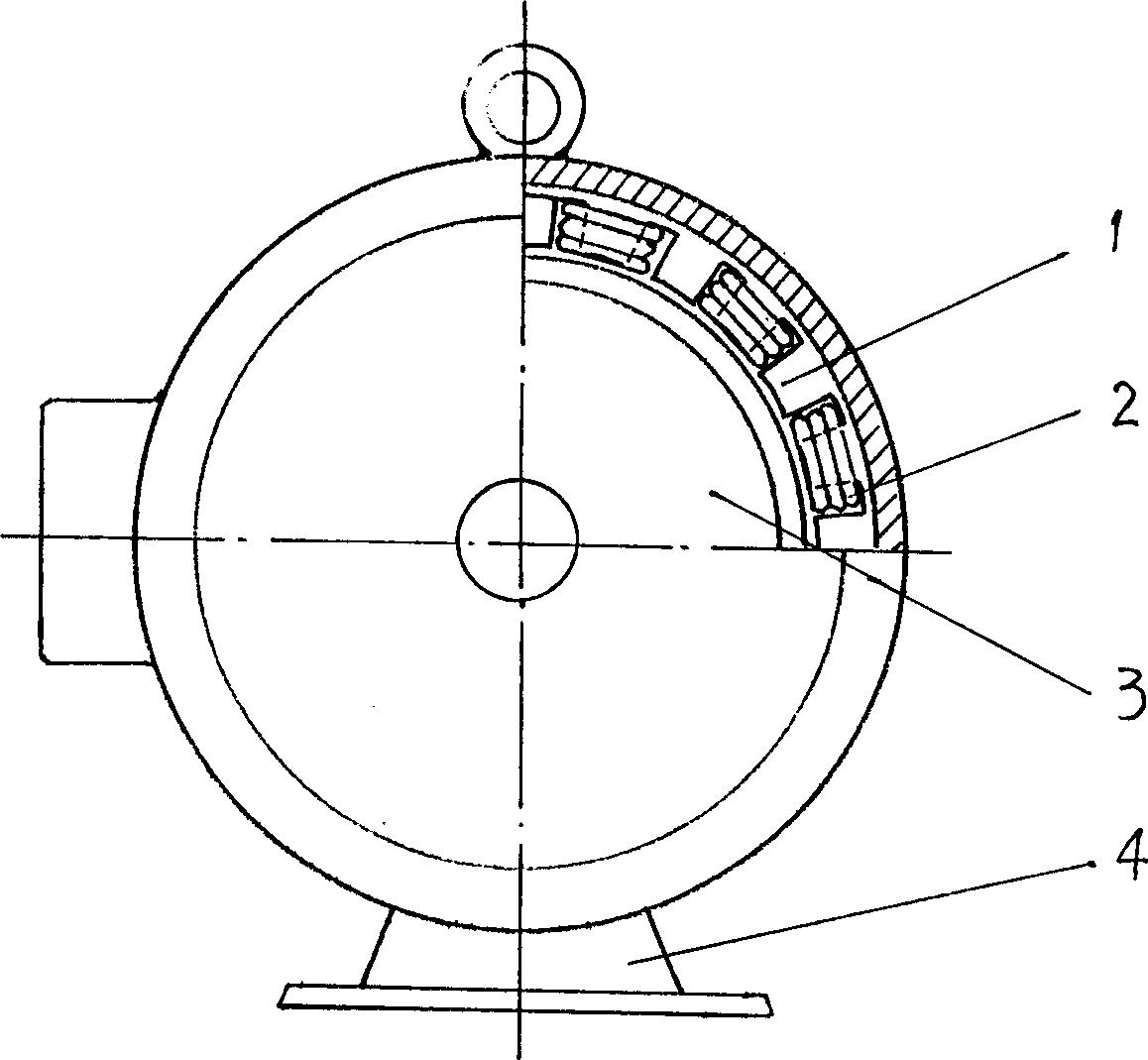

[0012] Such as figure 1 As shown, the stator core 1 is fixed on the base 4, and the three-phase stator winding 2 is arranged in the slot of the stator core 1. The stator core 1, the three-phase winding 2 and the frame 4 form the stator. A rotor 3 is connected in the middle of the stator to form a three-phase AC motor. Three-layer windings are arranged in the slots of the stator core 1 to form three-phase stator windings. Each phase winding occupies one layer in the stator core slots. The first ends (or tail ends) of the three-phase windings are spaced at 120° in turn, and are connected in a star or delta according to the conventional wiring method to form a three-phase AC generator or a three-phase AC motor. The motor rotor can be in the form of a rare earth permanent magnet rotor or a squirrel cage rotor.

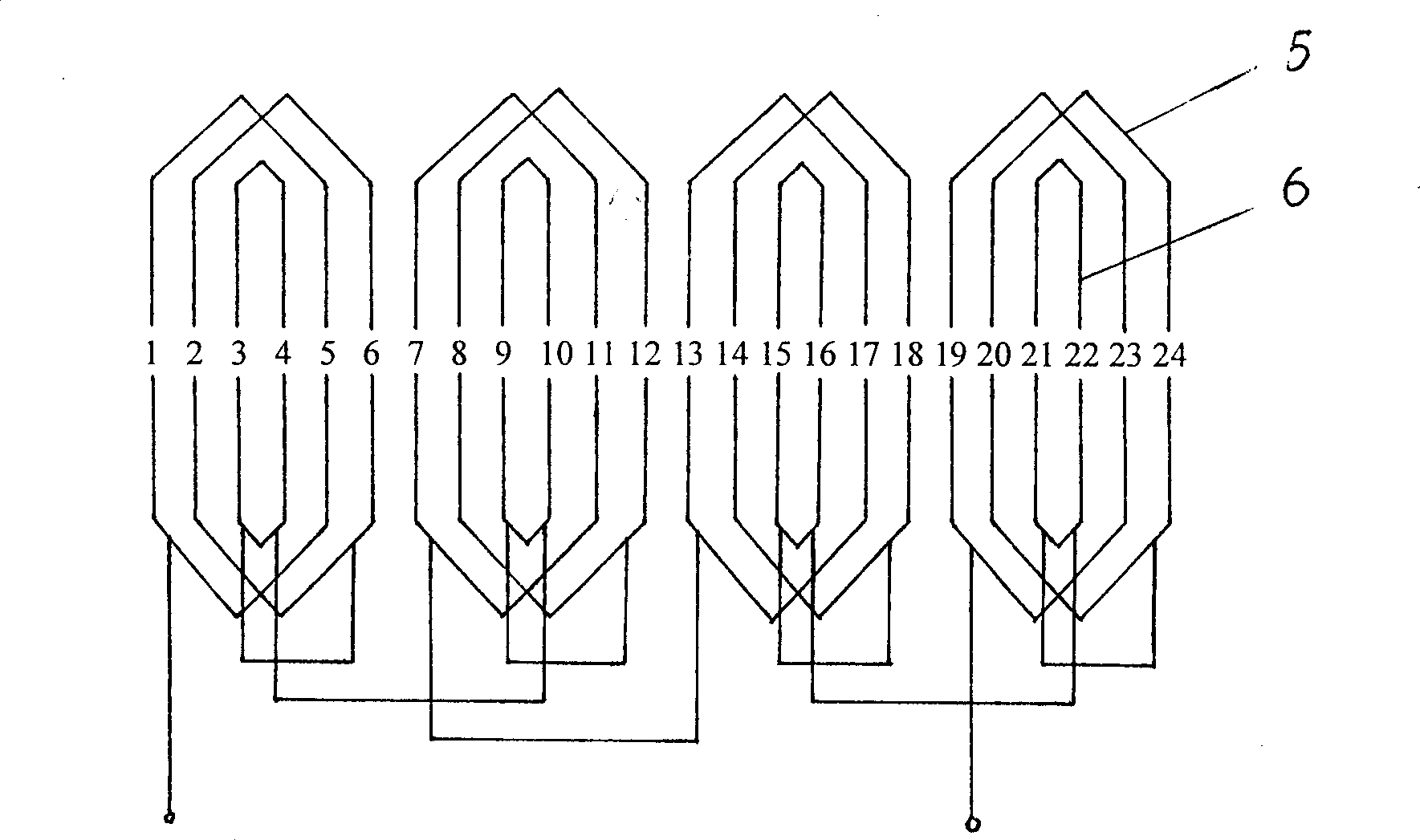

[0013] Each of the three-phase stator windings 2 has the same structure. figure 2 The winding form of each phase is that an auxiliary winding 6 is connected in serie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com