Linkage type cation chromatographic column and its preparation method

A cation chromatography and bonding technology is applied in the field of preparation of grafted cation chromatographic columns, which can solve the problem that the cation chromatographic column cannot analyze alkali metals at the same time, and achieve the effects of simple preparation process and low manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Embodiment 1: the manufacture process of cationic chromatographic column is as follows, and its steps are:

[0014] (1) First, 55% styrene-divinylbenzene microspheres were synthesized by emulsion polymerization, and the microspheres with a narrow distribution of about 8 μm were selected as the chromatographic packing matrix.

[0015] (2) Mix base balls and a certain amount of pyromellitic anhydride in a nitrobenzene environment, use anhydrous zinc chloride as a catalyst, stabilize the temperature at 50 degrees Celsius, react for 6 hours, take out the bonded microspheres and wash them with ethanol , and packed into the column by the homogenate method.

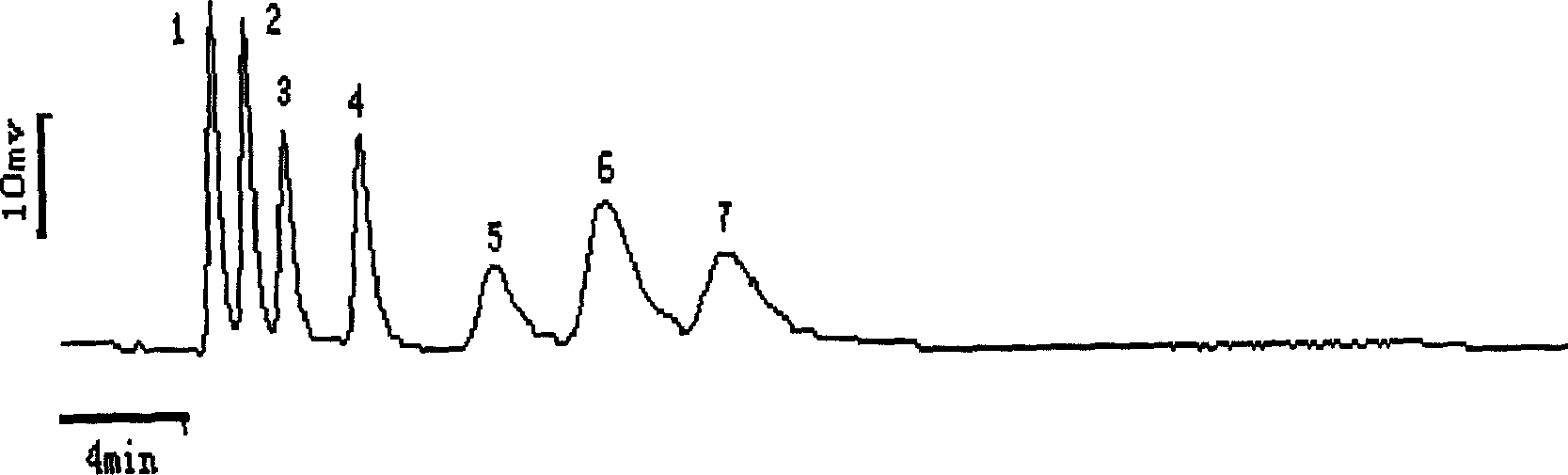

[0016] (3) adopting the sulfuric acid of 3mmol / L as eluent, flow velocity is 1ml / min, adopts the suppressed conductometric detector to alkali metal, ammonium

[0017] (4) and alkaline earth metal cations were detected.

[0018] (5) Ion chromatographic columns made of pyromellitic anhydride bonded with different concentr...

Embodiment 2

[0020] (1) Use 8 μm styrene-divinylbenzene polymer beads, wash and dry.

[0021] (2) Mix the base ball and a certain amount of vinylphosphonic acid in a nitrobenzene environment, use anhydrous aluminum chloride as a catalyst, and stabilize the temperature at 50 degrees Celsius, react for 6 hours, take out the bonded microspheres and wash them with ethanol , and packed into the column by the homogenate method.

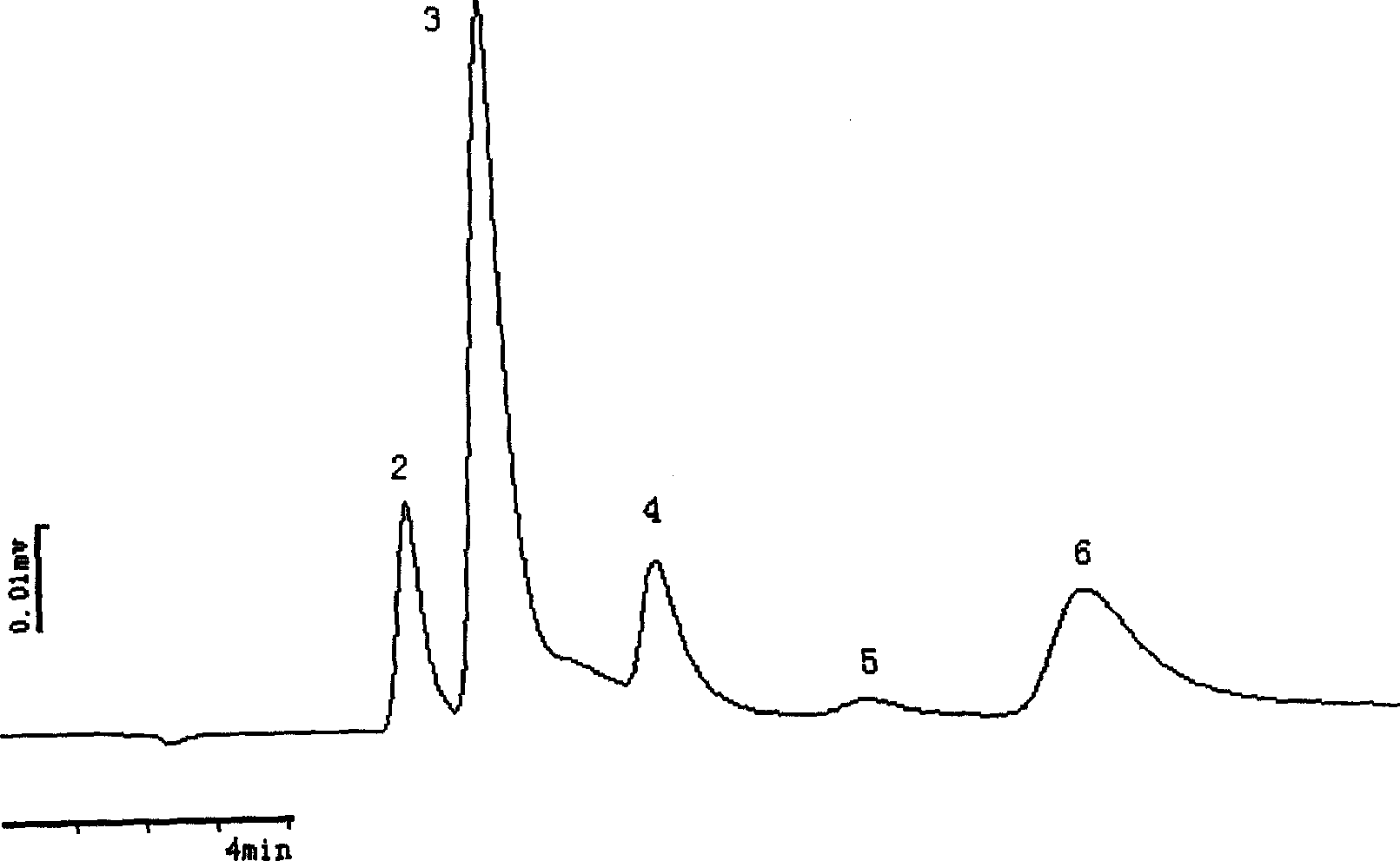

[0022] (3) The cation was determined by the method of Example 1 (3), and the result was consistent with 1 (4).

Embodiment 3

[0024] (1) Use 8 μm styrene-divinylbenzene polymer beads, wash and dry.

[0025] (2) Mix base balls and a certain amount of maleic anhydride in a nitrobenzene environment, use anhydrous zinc chloride as a catalyst, stabilize the temperature at 50 degrees Celsius, react for 6 hours, take out the bonded microspheres and wash them with ethanol clean, and packed into the column by the homogenization method.

[0026] (3) The cation was determined by the method of Example 1 (3), and the result was consistent with 1 (4).

[0027] (4) The exchange capacity of the cation chromatographic column made by this method is suitable, and the one-time injection separation of alkali metal and alkaline earth metal ions can be fully realized.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com