Suspension assembly and magnetic disk drive

A technology of disk drives and suspension components, applied in the direction of instruments, magnetic recording, arm parts, etc., can solve the problems of damaged bearings, heavy loads, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

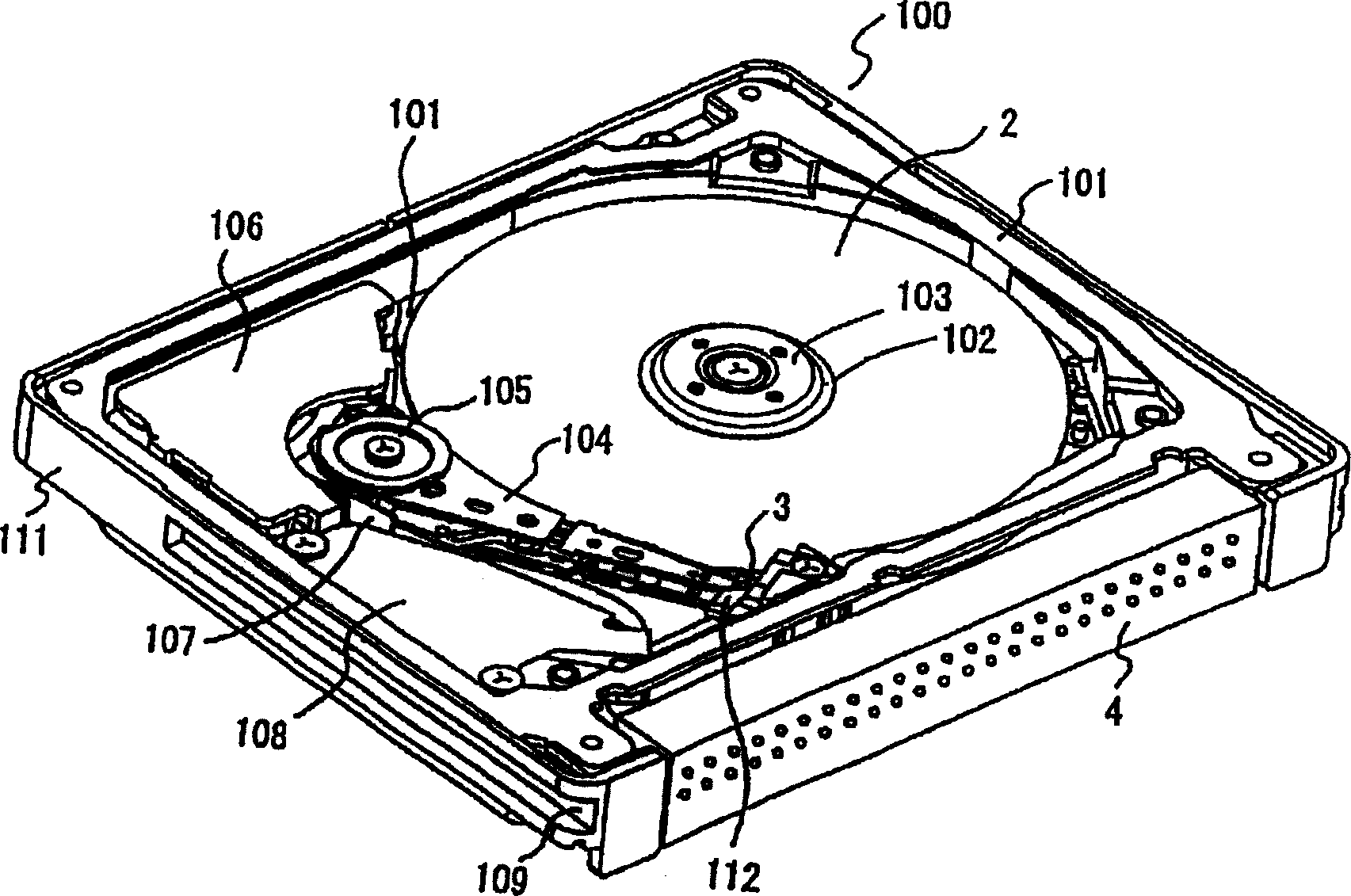

[0037] Referring to the accompanying drawings, preferred embodiments of the present invention will be described below. figure 2 Shown is a compact disk drive 100 compliant with the Compact Flash Type 2 standard and equipped with a suspension assembly 104 in accordance with a preferred embodiment of the present invention. The outer dimensions of the disk drive 100 are 42.8mm x 36.4mm x 5mm. The recording medium is a magnetic disk 2 with a diameter of 1 inch. The box-shaped base 101 is made by press working. A spindle motor (not shown) is fixedly mounted on the bottom wall of the base 101 . The spindle motor has a fluid dynamic bearing (FDB). The disk 2 is installed and fixed on the spindle 102 with a top plate 103 .

[0038] Suspension assembly 104 is mounted on a load bearing shaft 105 which is rotatably supported on the bottom wall of base 101 . The voice coil motor (VCM) fixedly installed on the bottom wall of the base 101 drives the suspension assembly 104 to rotate, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com