Transformer of zero-clearance magnetic circuit and less-clearance magnetic circuit

A transformer and zero-gap technology, applied in the field of new structure transformers, can solve the problems of inability to use grain-oriented electrical silicon steel sheets, reduce transformer efficiency, and low material utilization, and achieve the effects of reducing material costs, improving efficiency and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

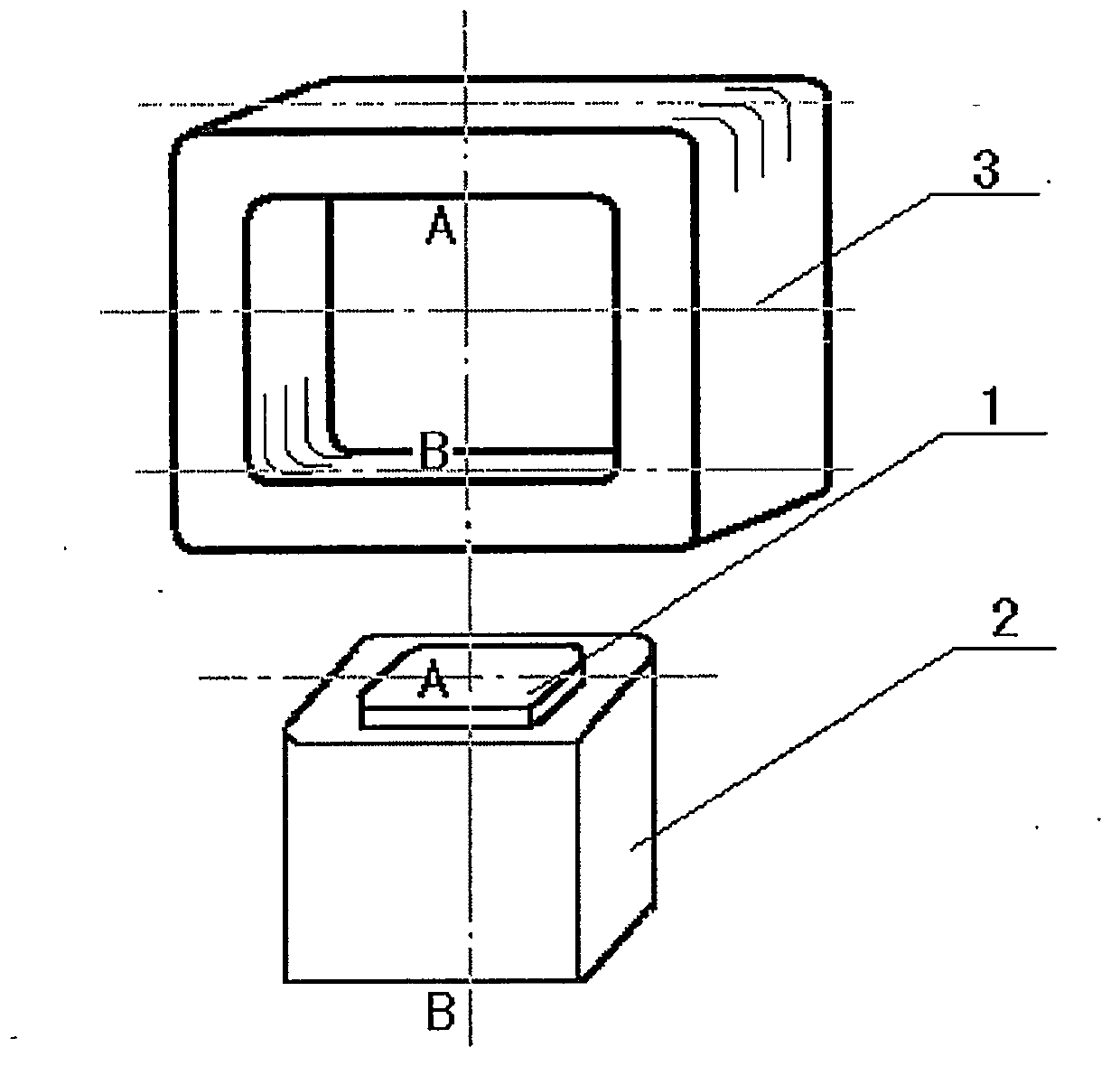

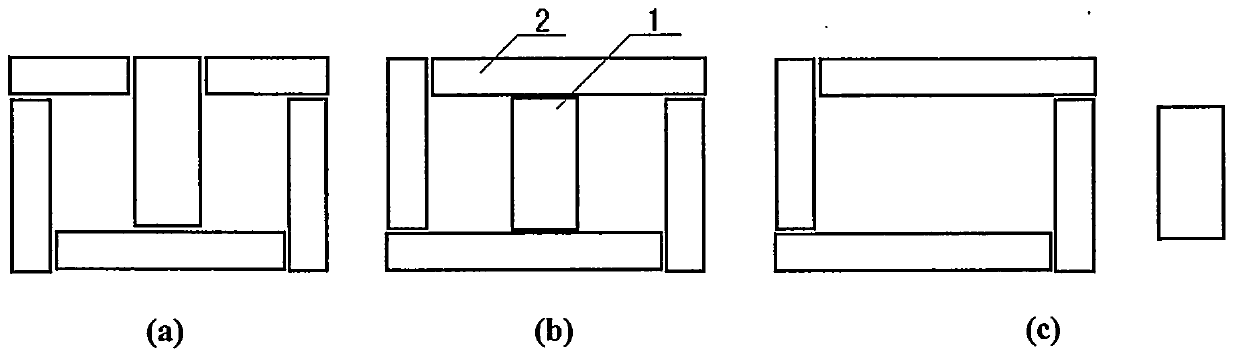

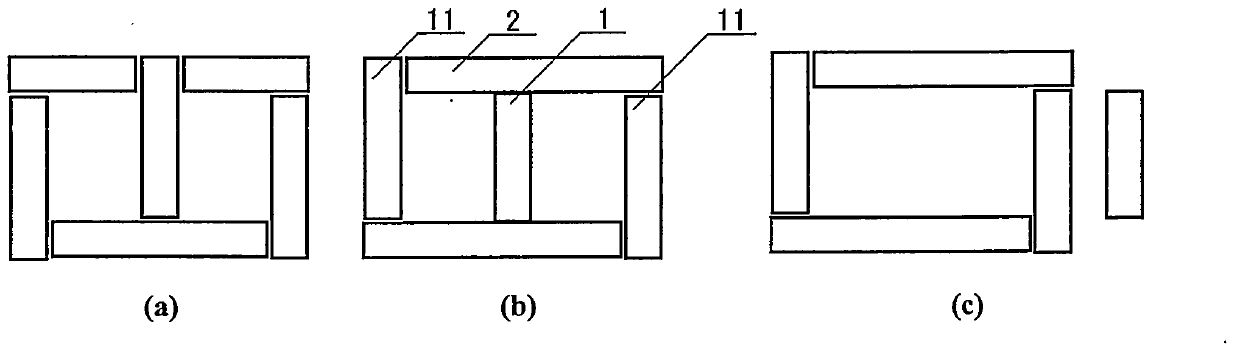

[0013] The main structure of the transformer structure of the present invention includes two parts - a winding and a magnetic circuit, and the magnetic circuit can be decomposed into an iron core and an iron yoke. The iron core (1) is a component for installing the winding, and is also the source of the magnetic force flow generated by the current in the winding. The winding (2) is an important part of electromagnetic coupling - the electric chain. The input current of the winding can generate magnetic force lines in the iron core, and can also generate induced voltage through the change of the magnetic force lines to output power, thereby outputting AC current outward. The iron yoke (3) is a passage for connecting the magnetic current (single phase) in the iron core or the magnetic current (three phase) between the iron cores, for the circulation of the magnetic field lines in the iron core, and completing the flux linkage. The iron core and the iron yoke form a magnetic circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com