Energy saving reactor with unlaminated core

A non-lamination type, reactor technology, applied in the direction of transformer/inductor magnetic core, circuit, electrical components, etc., can solve the problems of high manufacturing cost, reduce inductance, increase copper loss, etc., to reduce manufacturing difficulty and man-hours cost, reduce the magnetic circuit seam gap, and reduce the effect of copper loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

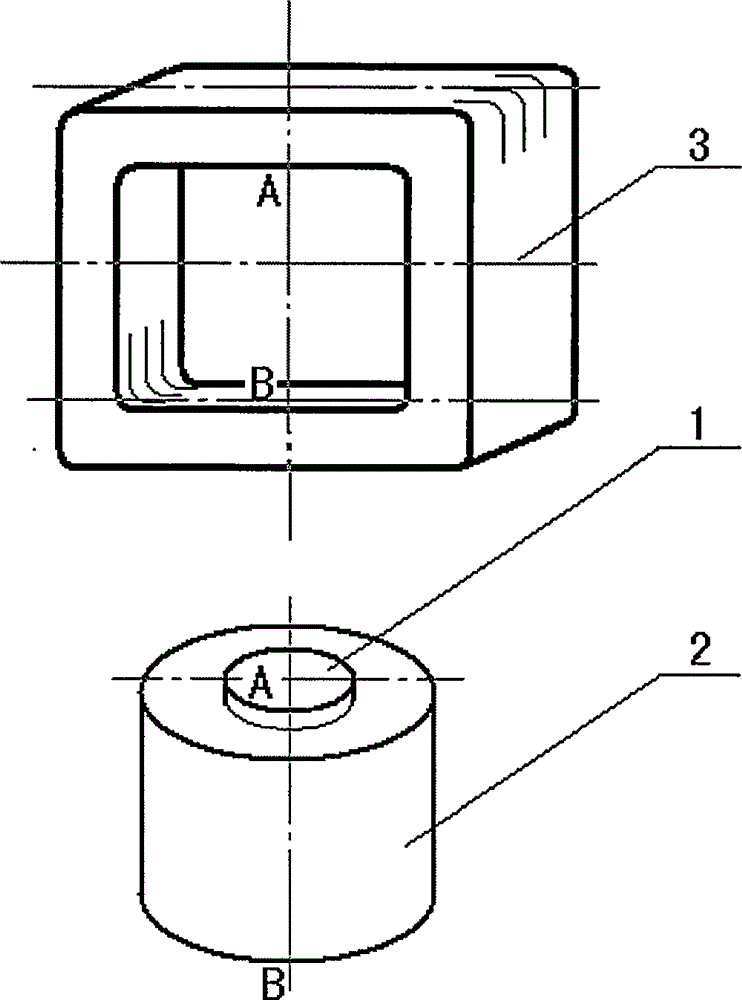

[0026] Reactor is an important electrical device, which is widely used in power system to limit power frequency overvoltage, eliminate generator self-excitation, limit operating overvoltage, line capacitive charging power, suppress potential supply current, limit short-circuit current, etc. Function. As a means of reactive power compensation, reactors are also indispensable in power systems. The reactor is also a filter device, which can filter out high-order harmonics, adjust power factor, and reduce grid voltage distortion.

[0027] The reactor of the invention is a high-efficiency energy-saving reactor with an iron core. Increasing the core of the reactor can increase the inductance of the reactor, reduce the volume and weight, and effectively reduce the copper loss.

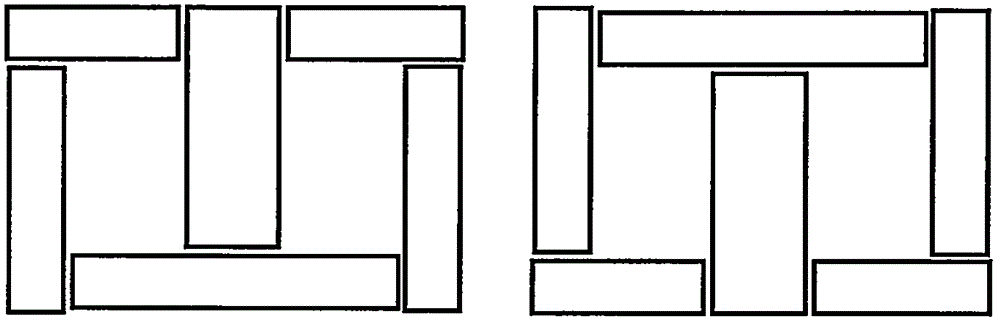

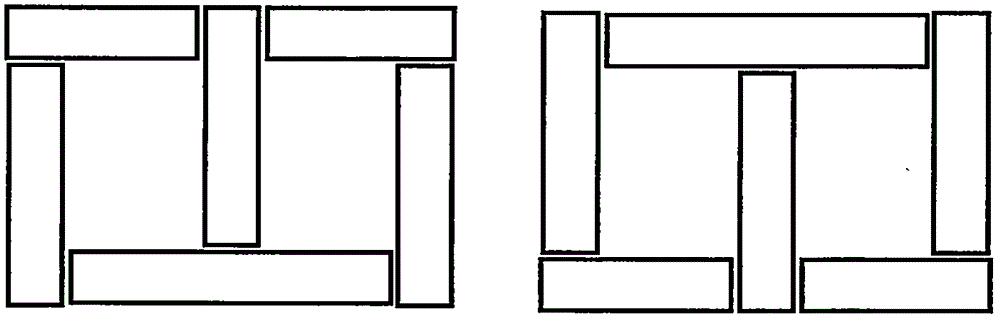

[0028] The definition of the magnetic circuit structure of the reactor of the present invention is different from that of the traditional reactor, and must be defined separately.

[0029] In the present in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com