Separated grid flash memory unit and its mfg. method

A technology for separating gates and memory cells, which is applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc. It can solve the problems of increasing component integration, increasing gate coupling rate, and failure to achieve, so as to increase the life of components , the effect of increasing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

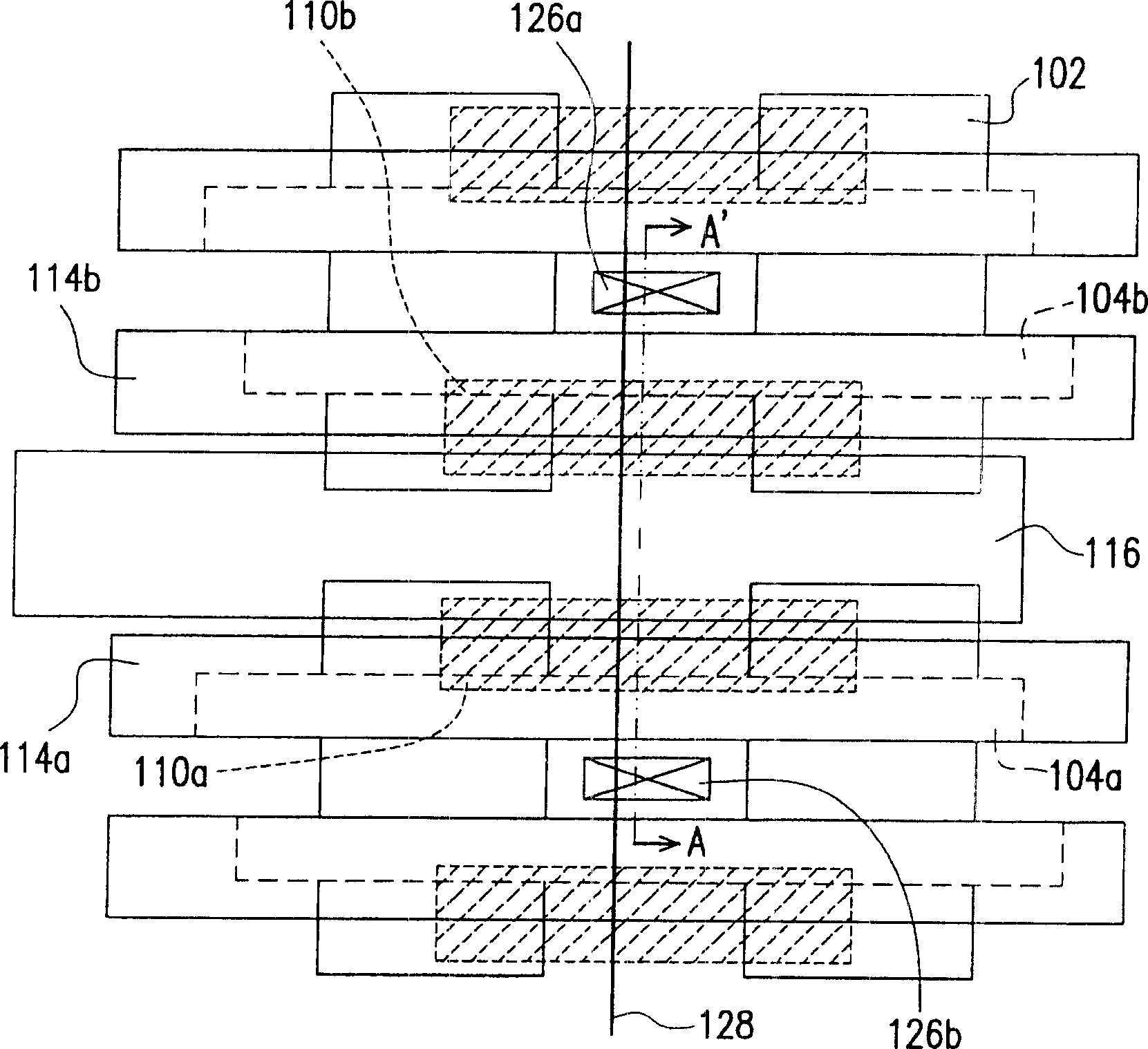

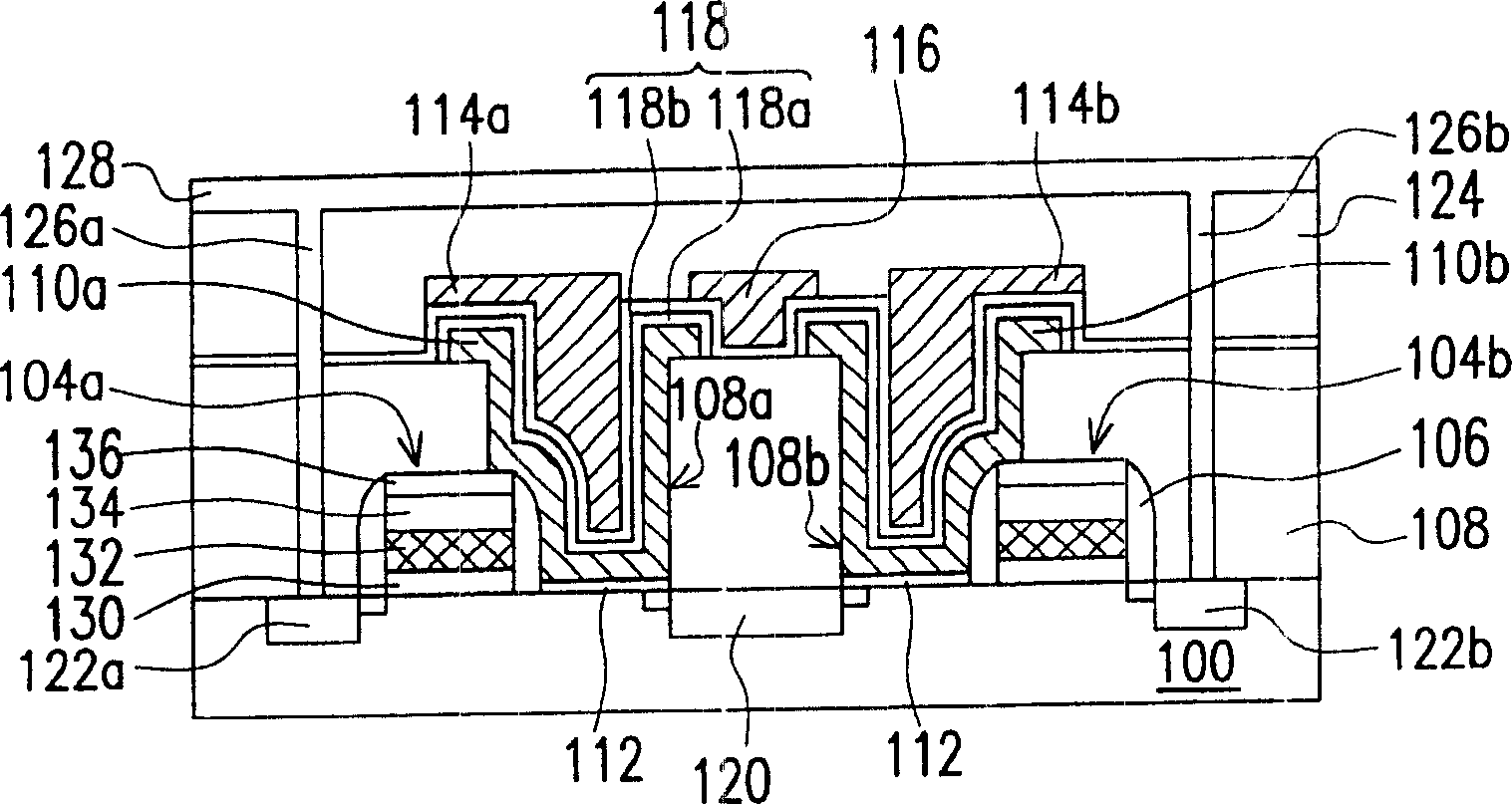

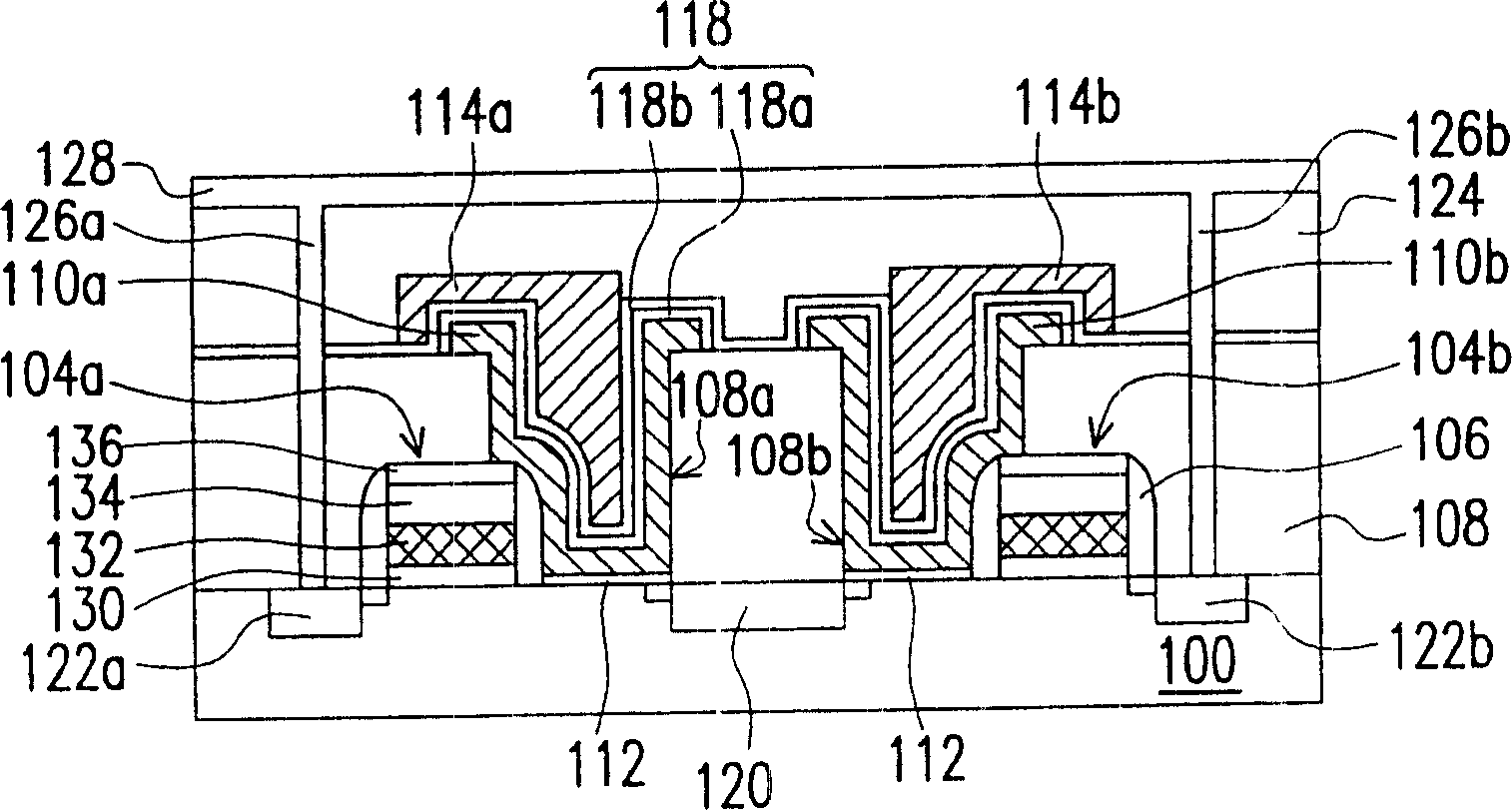

[0041] figure 1 Shown is a top view of a split gate flash memory cell according to an embodiment of the present invention. Figure 2A Shown is a cross-sectional view of the structure of the split-gate flash memory unit of the present invention. in, Figure 2A yes figure 1 The A-A line profile. Figure 2B Shown is a cross-sectional view of a split-gate flash memory cell according to another embodiment of the present invention. exist figure 1 , Figure 2A , Figure 2B In , the same components are given the same symbols, and descriptions thereof are omitted.

[0042] Please also refer to figure 1 and Figure 2A The flash memory unit of the present invention is composed of a substrate 100, an element isolation structure 102, a selection gate structure 104a and a selection gate structure 104b, a spacer 106, an interlayer dielectric layer 108, a floating gate 110a and a floating gate electrode 110b, tunneling dielectric layer 112, control gate 114a and control gate 114b, e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com