Method for making food model

A production method and food model technology, which are applied in the field of food model production, can solve the problems of inability to make fine textures on the surface of structured food, affect the turnover of restaurants, affect consumers, etc., so as to avoid food waste and the production method is simple and easy to implement. , easy-to-create effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention is described in detail below in conjunction with accompanying drawing

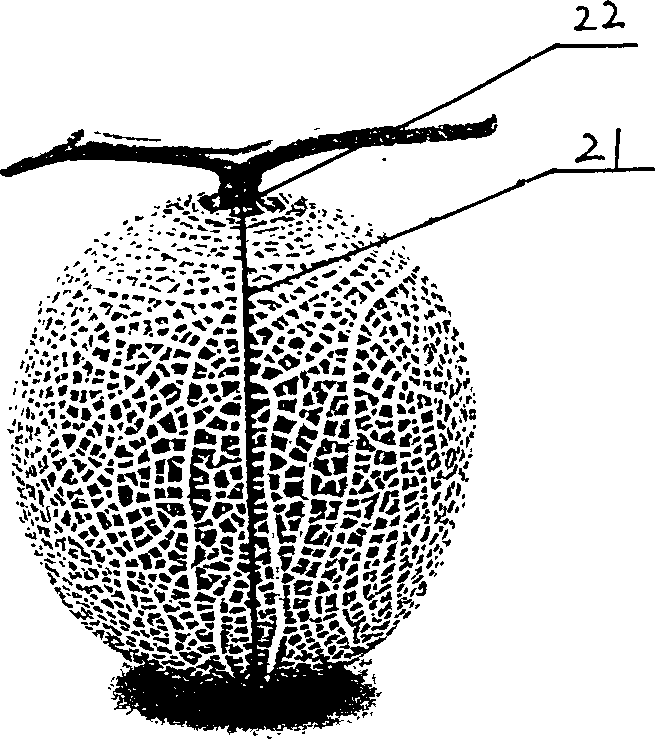

[0033] like figure 1 Shown, embodiment 1 is fruit cantaloupe, and the making method of its model is:

[0034] First divide the food into two units, the melon body and the vine, and make models separately. The following describes the production process of the melon body in detail

[0035] (1) Making molds

[0036] ① Take the mid-parting surface 21 of Hami melon as the parting surface;

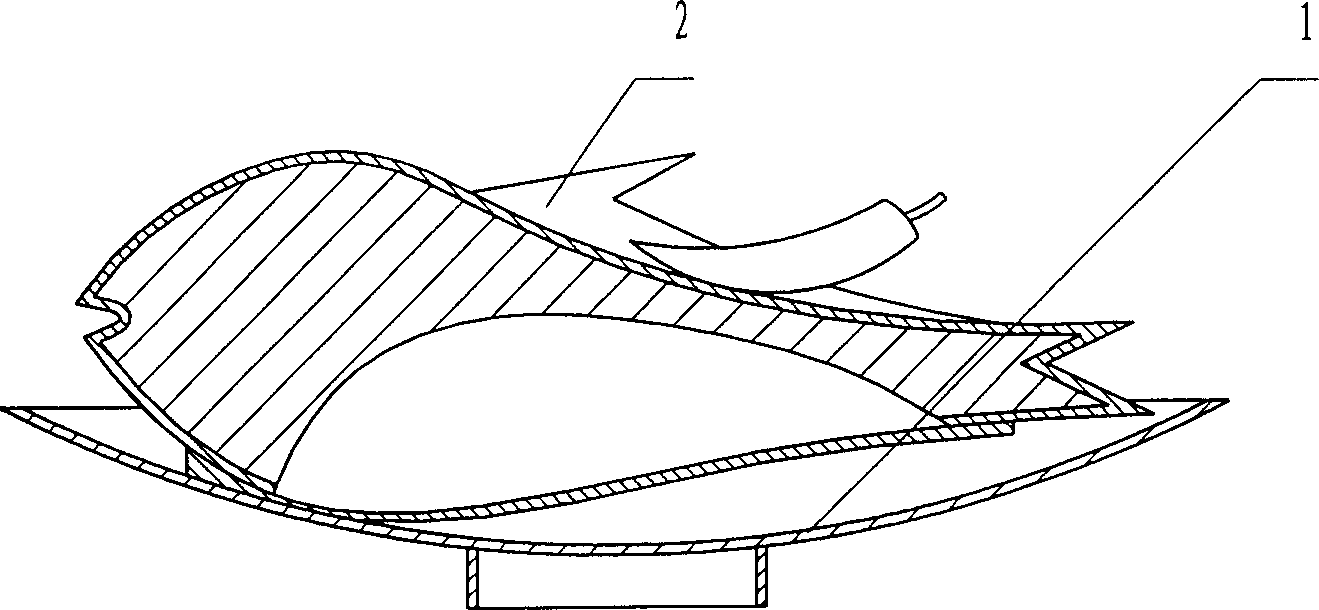

[0037] ②Make the inner mold, mix the matching 3-5% curing agent and 2-3% accelerator with silica gel, adjust evenly, and apply it on the surface of the cantaloupe. After the glue is dry, apply it twice again to form the inner mold;

[0038] ③Make the outer mold, apply soap liquid evenly on the outer wall of the inner mold, insert the parting insert at the parting surface, and coat or pour the well-mixed gypsum slurry on the outer wall of the inner mold on both sides of the parting insert, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com