Waterproof structure for deck and construction method thereof

A waterproof structure and construction method technology, applied in bridges, bridge parts, bridge construction, etc., can solve problems such as poor adhesion, uneven distribution of thermoplastic resin granules, increased construction costs, etc., and achieve good adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

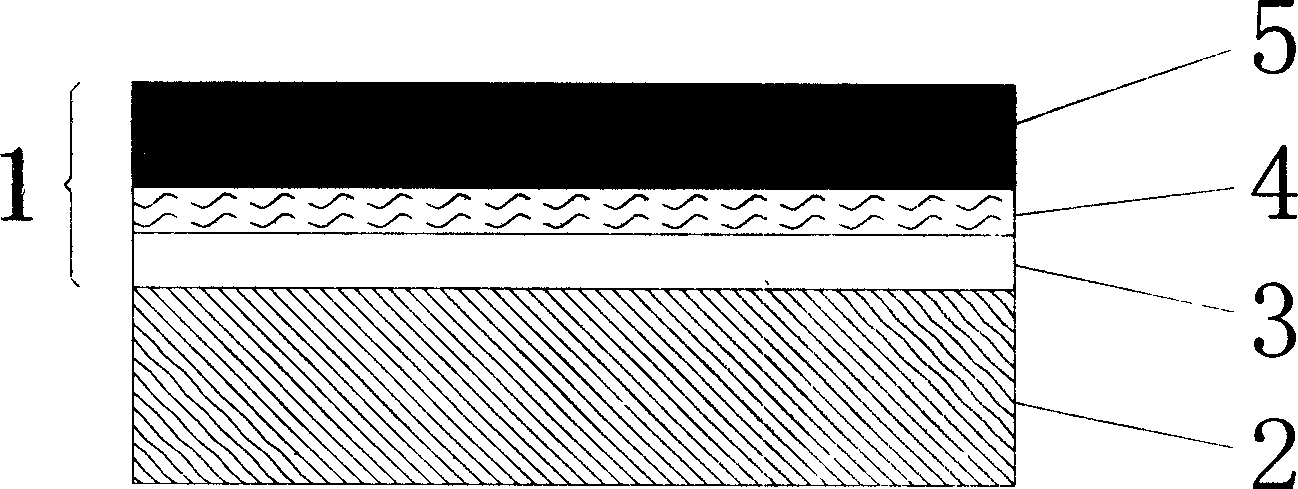

Embodiment 1

[0012] First coat a layer of primer on the bridge deck 2. The primer is epoxy resin paint. When painting the primer, spread light sand on the primer at the same time. The purpose of this is to prevent the deviation between the waterproof layer and the bridge deck. After the primer is painted on the bridge surface, apply the waterproof layer 3 again, the resin used for the waterproof layer of the present invention is polyurethane resin, and the brushing of the waterproof layer 3 adopts a roller to coat; layer 4, the configured plate layer 4 is made of a thermoplastic resin with a softening point of 100°C; after the plate layer 4 is paved, the last process is to add hot asphalt mixture Layer 5 is finished, and the asphalt and aggregate mixture that is usually used for paving is heated to 150°C and spread on the plate layer 4, so that the whole bridge deck waterproofing system has just been constructed.

[0013] The following is a routine performance test of the above-mentioned b...

Embodiment 2

[0016] First coat a layer of primer on the bridge deck 2. The primer is made of polyurethane resin paint. When the primer is painted, light sand is spread on the primer at the same time. The purpose of doing this is to prevent the deviation between the waterproof layer and the bridge deck. After the primer is painted on the bridge surface, the waterproof layer 3 is coated again. The resin used for the waterproof layer of the present invention is acrylic resin, and the brushing of the waterproof layer 3 adopts a roller to coat; After the plate layer 4 is finished, the configured plate layer 4 is made of a thermoplastic resin with a softening point of 120°C; after the plate layer 4 is laid, the last process is to add hot asphalt mixture The paving layer 5 is completed, and the asphalt and aggregate mixture that is usually used for paving is heated to 160° C. and paved on the plate layer 4, so that the whole bridge deck waterproofing system has just been constructed.

[0017] The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com