A photographic printing method for color photos

A color photo and image printing technology, which is applied in printing equipment, printing equipment, optics, etc., can solve the problems of low photosensitive pixels and insufficient photocopying, and achieve the effect of clear image, bright color, and resolution resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

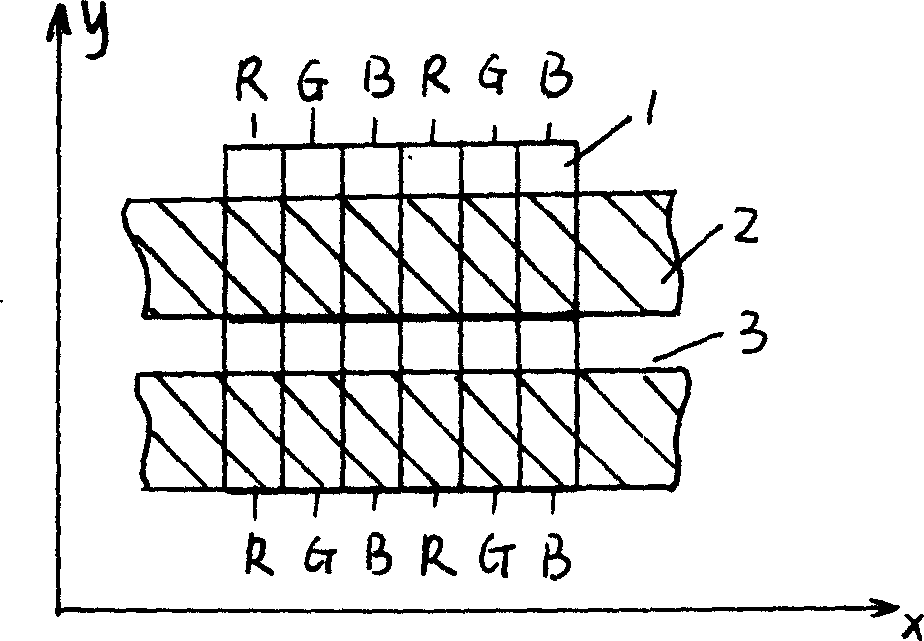

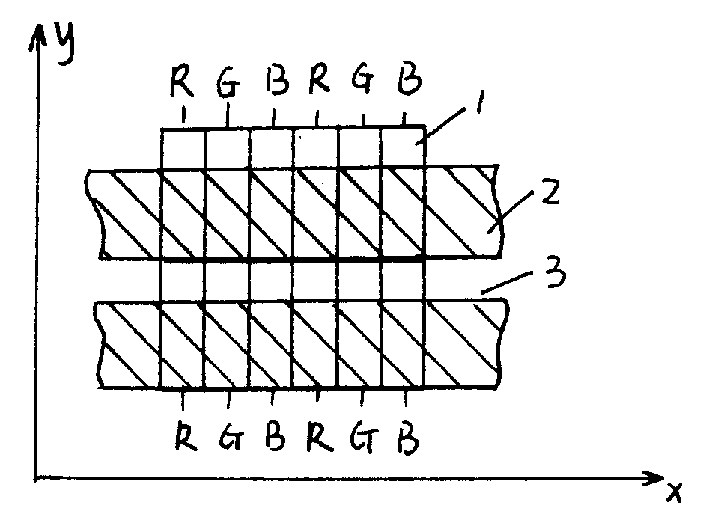

Embodiment 1

[0012] Embodiment 1: the grating covered on the surface of a 20.1-inch liquid crystal display screen with a dot pitch of 0.255m / m, the transparent gap is 0.09m / m, and the grating is made of transparent plastic material, such as PVC or other polyester transparent objects. At this time, the part through the grating is one-third of the display screen, and the display screen is displaced. The distance of each displacement is exactly one-third of the dot pitch of the display screen. After the display screen has been displaced three times vertically and three times horizontally , the pixels of the LCD screen are enlarged by 9 times. At this time, the photo paper is exposed step by step. The exposure time is 0.2-10 seconds. The photo paper after exposure is transferred to the color photo paper processing machine for washing. 45 seconds, turn to the bleaching tank to bleach for 45 seconds, then enter the two stabilization tanks in turn, stabilize for 45 seconds respectively, and finall...

Embodiment 2

[0013] Embodiment 2: The surface of a liquid crystal display screen with a 19-inch dot pitch of 0.294m / m is covered with a grating gap of 0.1m / m, and one-third of the display screen passes through the gap of the grating. After moving vertically and horizontally several times in the horizontal plane, the pixels of the liquid crystal display screen have also been enlarged several times, and after step-by-step exposure, repeat the developing process of Embodiment 1 to obtain high-definition photos.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com