Highly-transparent fiber glass-surface paper and its preparation method

A glass surface paper and fiber technology, which is applied in the direction of non-fiber pulp addition, fiber raw material treatment, paper, etc., can solve the problems of reducing light transmission performance, rough surface, poor flatness, etc., and achieves wide application range, simple preparation method, The effect of improving light transmission and surface smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

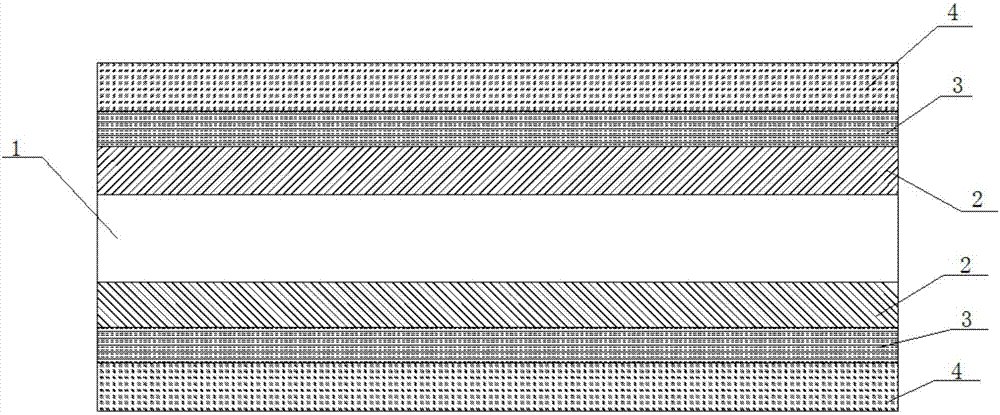

[0021] A high light-transmitting fiberglass surface paper, comprising sulfuric acid paper, coated with primer, secondary coating and protective layer in sequence on both sides of the sulfuric acid paper, the primer layer is made of carbon dioxide copolymer polyol 80 parts, 18 parts of diisocyanate, 22 parts of chain-extending cross-linking agent and 14 parts of hydrophilic chain-extending agent; 7 parts, 16 parts of ethyl acetate, 0.3 parts of white mineral oil and 10 parts of dyes; the protective layer is made of 27 parts of hydroxyethyl cellulose ether, 2 parts of sodium lauryl sulfate, 4 parts of polyacrylamide and Prepared from 6 parts of triethanolamine.

[0022] A preparation method of high light-transmitting fiber glass surface paper, comprising the following steps:

[0023] 1) Select surface density as 160g / m 2 , a sulfuric acid paper with a thickness of 0.04mm is used as the base layer, and is set aside;

[0024] 2) Put 80 parts of carbon dioxide copolymer polyol, ...

Embodiment 2

[0032] A high light-transmitting fiberglass surface paper, comprising sulfuric acid paper, coated with primer, secondary coating and protective layer in sequence on both sides of the sulfuric acid paper, the primer layer is made of carbon dioxide copolymer polyol 80 parts, 18 parts of diisocyanate, 22 parts of chain-extending cross-linking agent and 14 parts of hydrophilic chain-extending agent; 7 parts, 16 parts of ethyl acetate, 0.3 parts of white mineral oil and 10 parts of dyes; the protective layer is made of 27 parts of hydroxyethyl cellulose ether, 2 parts of sodium lauryl sulfate, 4 parts of polyacrylamide and Prepared from 6 parts of triethanolamine.

[0033] A preparation method of high light-transmitting fiber glass surface paper, comprising the following steps:

[0034] 1) Select surface density as 160g / m 2 , a sulfuric acid paper with a thickness of 0.04mm is used as the base layer, and is set aside;

[0035] 2) Put 80 parts of carbon dioxide copolymer polyol, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com