Preparation method of high activity cuprous chloride catalyst used for organic silicon monomer synthesis

A cuprous chloride, high-activity technology, applied in the direction of catalyst activation/preparation, physical/chemical process catalyst, cupric chloride, etc., can solve the problems of high energy consumption and cumbersome operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific examples.

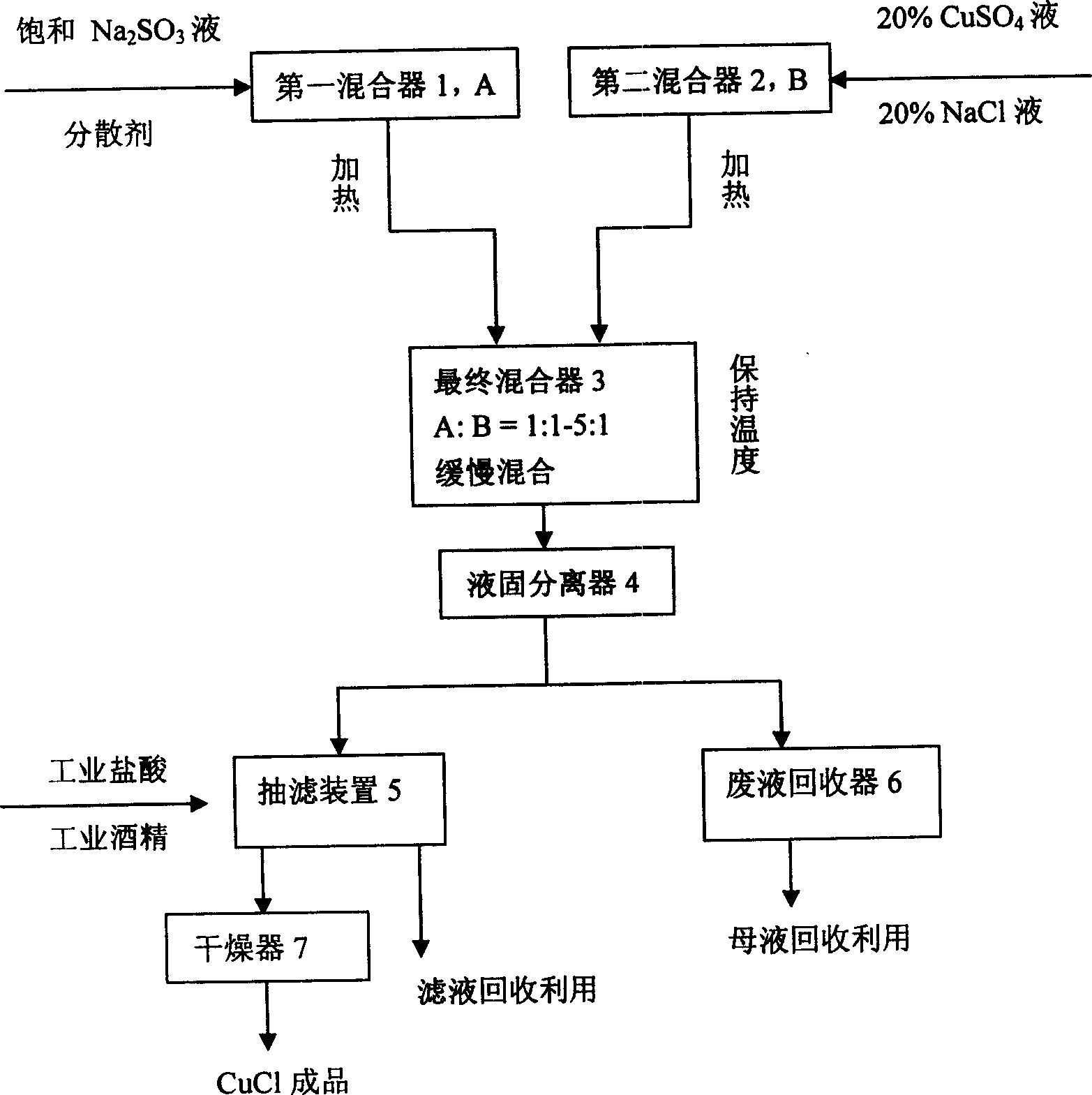

[0020] Such as figure 1 Shown, saturated Na 2 SO 3 Add the solution and a certain amount of dispersant into the first mixer 1 to fully dissolve the dispersant; at the same time, add NaCl and CuSO 4 Add deionized water into the second mixer 2 according to the mass ratio of 0.5-2, and the composition contains 10-30% CuSO 4 , 5 ~ 60% NaCl mixed solution. The solution from the first mixer 1 and the solution from the second mixer 2 are uniformly heated to 30-100°C, optimally 60-90°C, and then enter the final mixer according to the mass ratio of 1:1-5:1 3, fully stirred and mixed, and then the reduction reaction occurred while keeping the temperature constant. The added amount of the dispersant is 0.05-5% of the total mass of the solution in the final mixer 3 . After stirring for 0.5-5 hours, the mixed solution containing the precipitated CuCl is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com