Rotating engine

A rotary engine and rotor technology, applied to rotary piston engines, rotary or oscillating piston engines, combustion engines, etc., can solve the problems of increased difficulty in processing and manufacturing, friction and seizure, etc., and achieve low cost of use and easy operation The effect of convenience and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

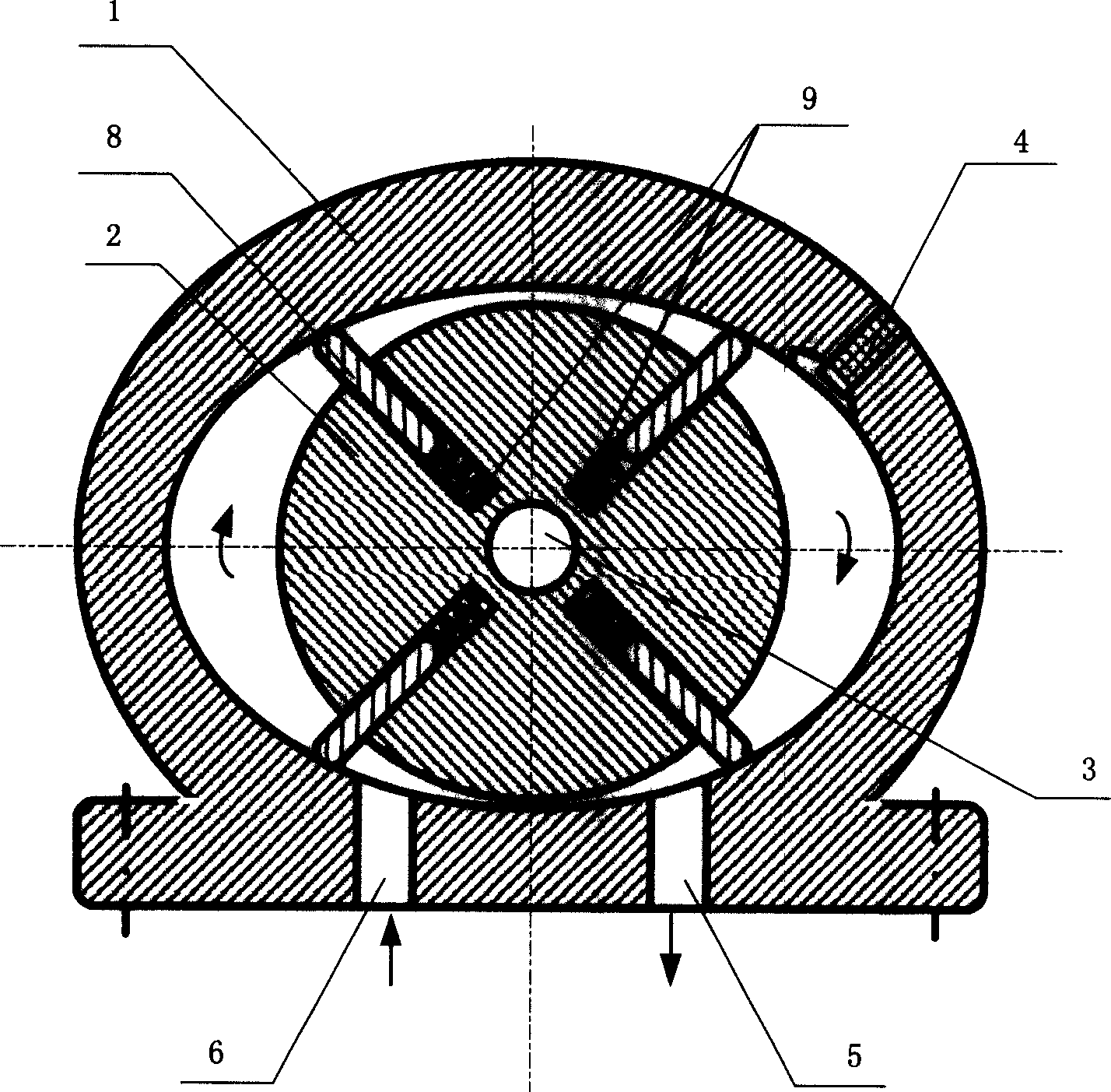

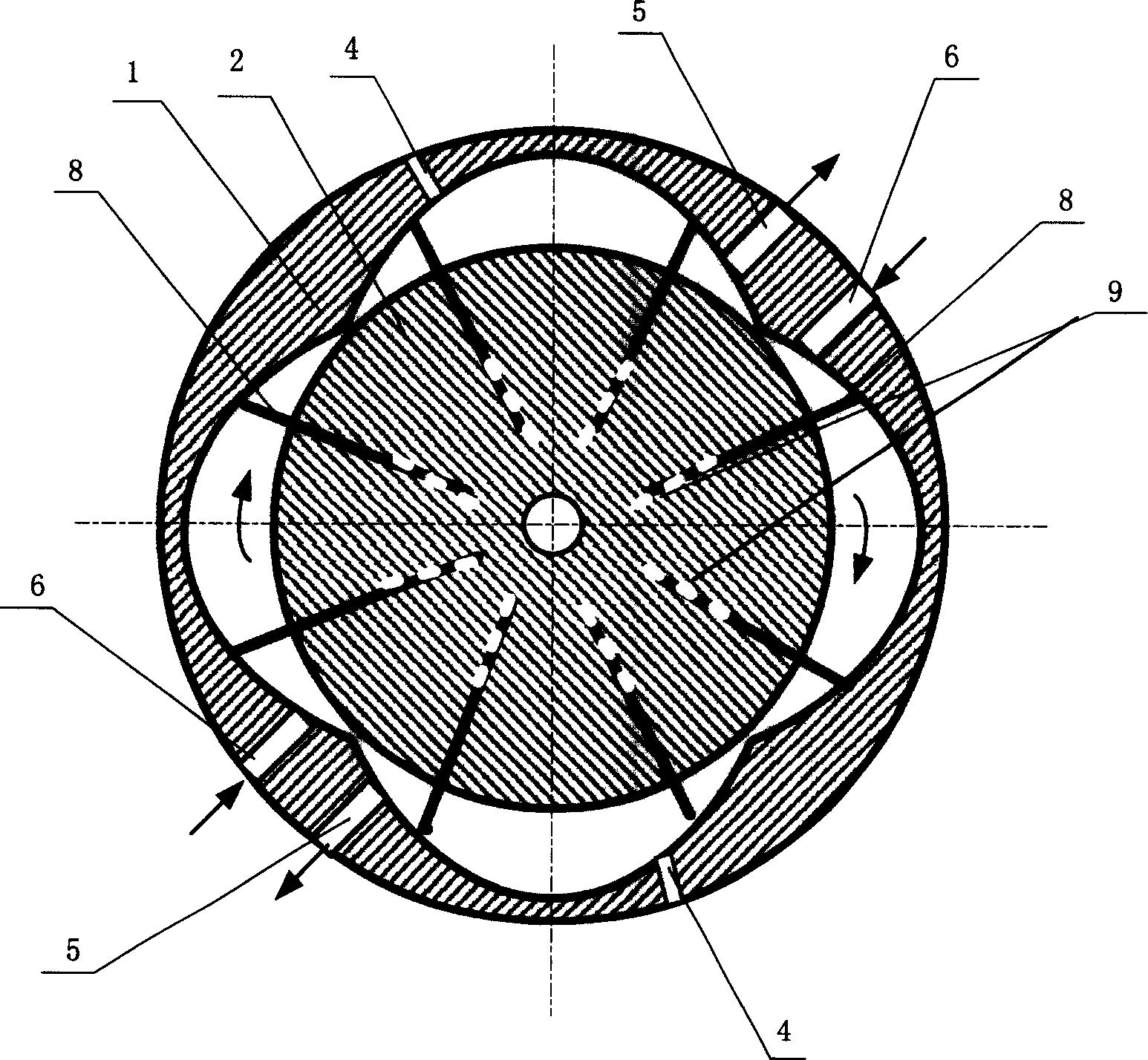

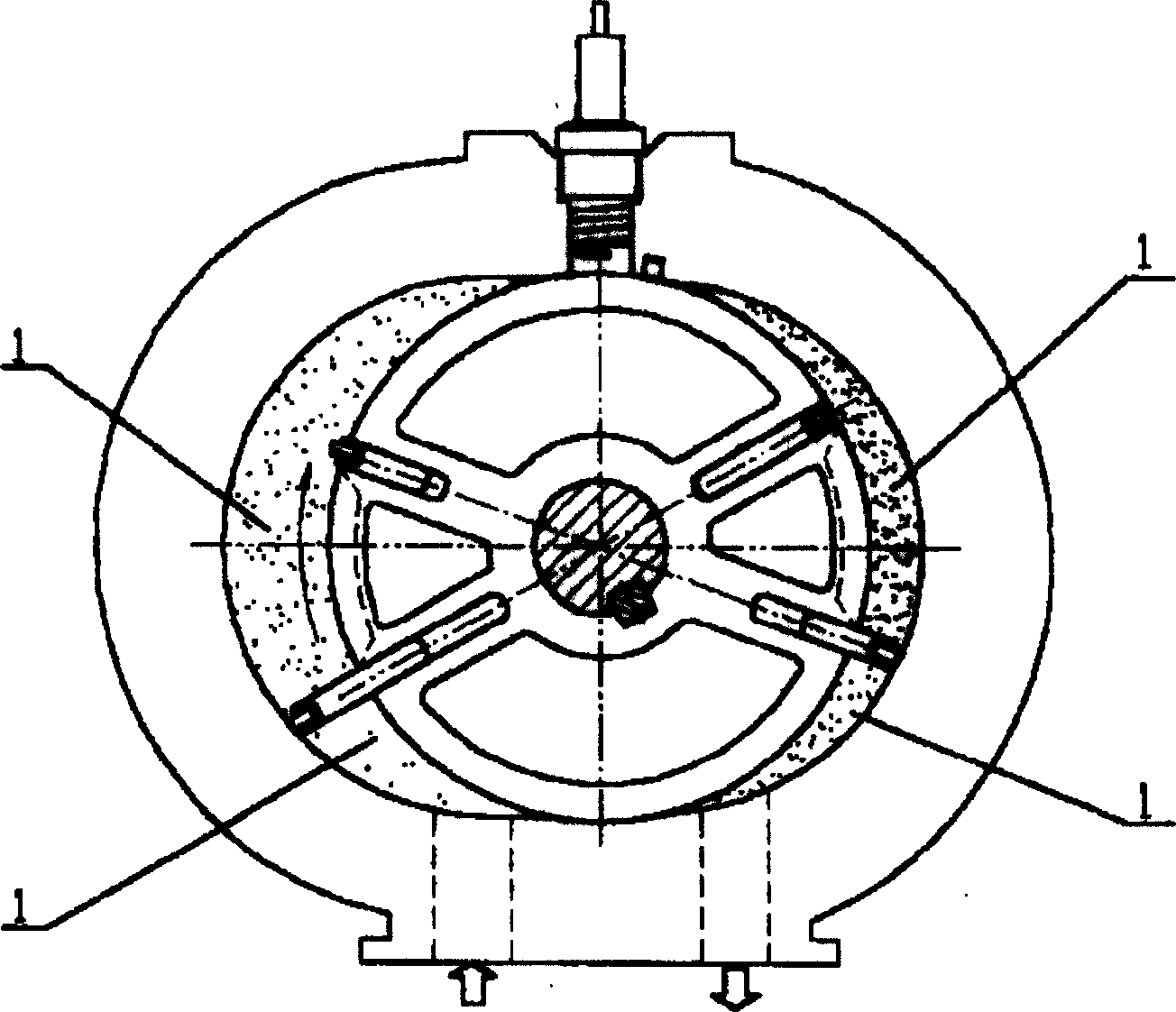

[0019] Embodiment 1: as attached Figure 4 And attached Figure 5 As shown, the rotary engine of the present invention is composed of an elliptical cylindrical stator, a rotor, a stator end cover, a shaft, a bearing, a machine base, etc., and the elliptical cylindrical stator 1 and rotor 2 are coaxial and They are not in contact with each other, and there is a gap for compressed gas to pass through; the rotor 2 divides the inner cavity of the stator 1 into two arc chambers 20 and 20', one of which communicates with the mixed gas inlet 6, and the other arc chamber The arc-shaped chamber 20' communicates with the exhaust port 5, and the ignition device 4 is installed in the arc-shaped chamber 20'.

[0020] The rotor 2 cooperates with the shaft 3 through the key 10. There are four grooves parallel to the shaft symmetrically on the rotor 2. Each groove is equipped with a spring 9 and a slide plate 8. The slide plate 8 can move radially in the groove. The spring 9 Push the slide ...

Embodiment 2

[0022] Embodiment 2: as attached Figure 4 And attached Figure 5 As shown, the structure is the same as in Example 1, the inner diameter of the minor axis of the elliptical cylindrical cavity of the stator 1 is 204mm, and the inner diameter of the major axis is 240mm; the diameter of the rotor 2 is 200mm; the diameter of the shaft 3 is 60mm; the slide plate in the groove The thickness of 8 is 8mm; the inner cavity of stator 1 and the height of rotor 2 are both 110mm; three spring seats are arranged in each channel, and small springs 9 are installed respectively; the corresponding included angle between ignition device 4 and exhaust port 5 is 117°±8'; the stator 1 is provided with several channels 7 for the flow of cooling liquid (water), and several cooling fins are also provided on the outer surface.

Embodiment 3

[0023] Embodiment 3: the same structure as Embodiment 1, as attached figure 1 And attached figure 2 As shown, a prototype of a rotary engine has been manufactured, the inner diameter of the minor axis of the elliptical cylindrical cavity of the stator 1 is 102mm, and the inner diameter of the major axis is 120mm; the diameter of the rotor 2 is 100mm; the diameter of the shaft 3 is 30mm; The thickness of the slide plate 8 is 5mm; the inner cavity of the stator 1 and the height of the rotor 2 are both 60mm; two spring seats are arranged in each channel, and a small spring 9 is installed respectively; the corresponding included angle between the ignition device 4 and the exhaust port 5 It is 116°±8'; there are several cooling fins on the outer surface.

[0024] As in the rotary engine described in Embodiment 1-3, during operation, the gas is inhaled after one of the slides passes through the gas inlet 6, and the gas between the two slides is sucked by the next adjacent slide a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com