Polyvinylacetal resin for paint and ink and paint and ink composition

A polyvinyl acetal resin, polyvinyl alcohol technology, applied in polyacetal coatings, inks, applications, etc., can solve the problems of producing irritating odor, reducing pigment dispersibility, and increasing the viscosity of paint and ink compositions, To achieve the effect of high storage stability and enhanced dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

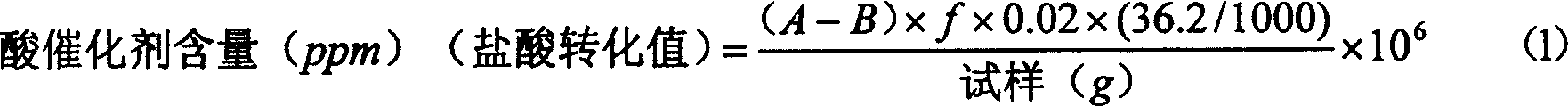

Embodiment 1

[0037] In a 5-liter separable flask, after heating and dissolving 280 g of polyvinyl alcohol (polymerization degree 230, saponification degree 99.0 mol%) in 3200 g of distilled water, the solution was kept at 0° C., and 82 g of 35 wt % hydrochloric acid was added to To this solution, 150 g of n-butyraldehyde was then added to the solution. After adding n-butyraldehyde for 1 hour, the temperature of the solution was raised to 25° C. for 4 hours.

[0038] After the reaction was completed, the obtained resin was washed with distilled water, and the washed resin was redispersed in distilled water, and sodium hydroxide was added to adjust the pH of the resin dispersion to 7. The dispersion was heated to a temperature of 40°C, maintained at this condition for 5 hours, and then cooled to room temperature.

[0039] Secondly, wash the obtained resin with 500 times the amount of distilled water of the solid content, redisperse the washed resin in distilled water, then keep the resin di...

Embodiment 2

[0042] The polyvinyl acetal resin and ink were prepared following the same process as in Example 1, except that polyvinyl alcohol with a degree of polymerization of 250 and a degree of saponification of 97.0 mol% was used, and the aldehyde used was n-butyraldehyde.

Embodiment 3

[0044] The polyvinyl acetal resin and ink were prepared following the same process as in Example 1, except that polyvinyl alcohol with a degree of polymerization of 800 and a degree of saponification of 99.0 mol% was used, and the aldehyde used was n-butyraldehyde.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com