Catalytic converting method for improving petrol octane number

A catalytic conversion method and gasoline octane number technology, which is applied in the direction of naphtha catalytic reforming, etc., can solve the problems of large gasoline consumption and achieve the effects of increasing octane number, reducing energy consumption, and reducing sulfur content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

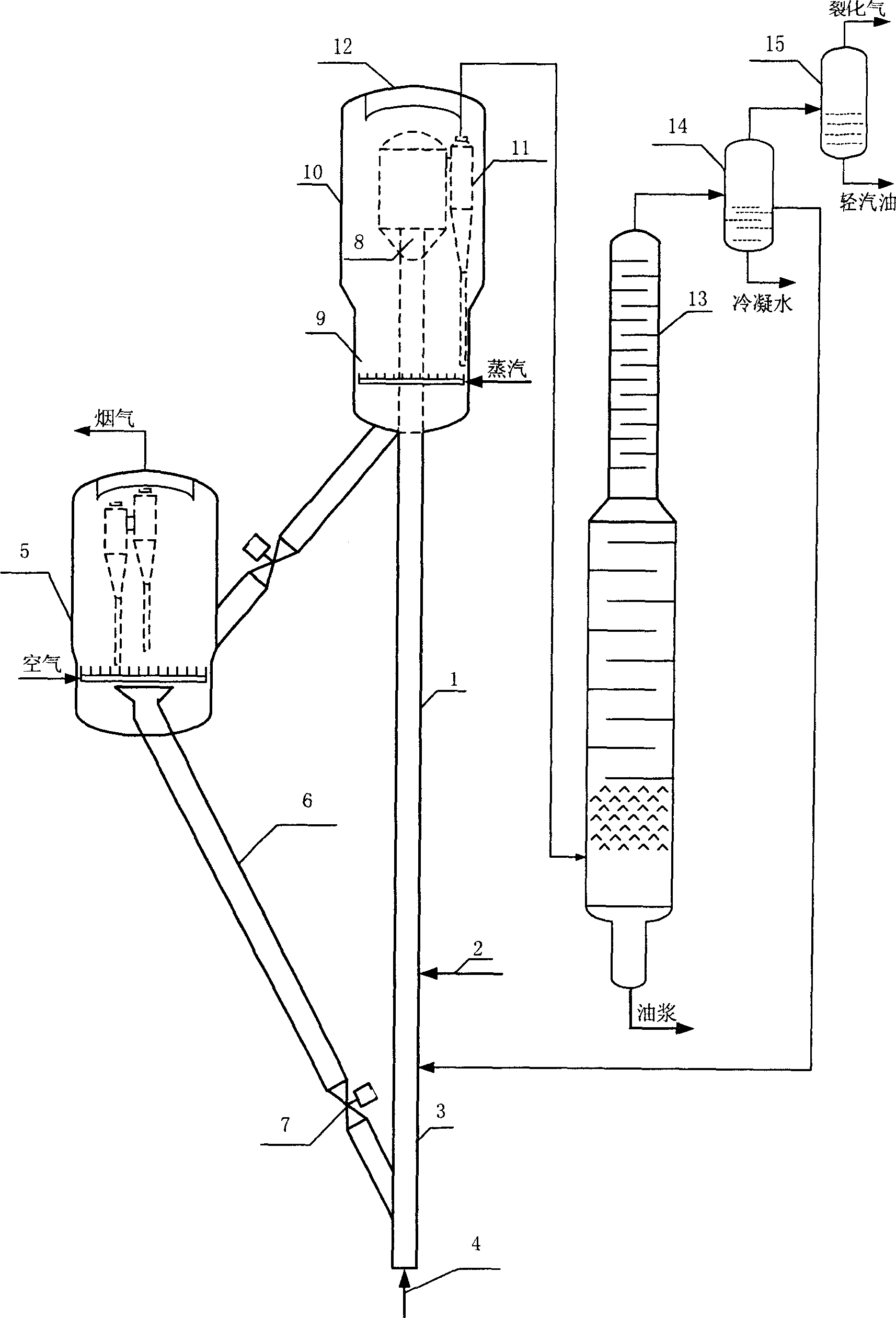

Method used

Image

Examples

Embodiment 1

[0028] This example illustrates that the octane number of catalytically cracked gasoline can be further increased by adopting the method provided by the invention. The test was carried out on a medium-sized riser catalytic cracking unit.

[0029]Catalytic gasoline A (RON, MON are 87.5,78.2 respectively, olefin content is 23.1% by weight) that boiling range is 110-205 ℃ enters the first reaction section from 1.2 meters below the catalytic cracking raw material nozzle, contacts with catalyst C, in The reaction was carried out under the conditions that the reaction temperature was 650° C., the residence time was 0.5 seconds, and the solvent-to-oil ratio was 6. The reacted oil gas and the reacted catalyst enter the FCC raw material cracking section (the second reaction section); the FCC raw material oil enters the reactor from the bottom of the second reaction section, and contacts with the reacted oil gas and catalyst from the first reaction section, and the generated oil gas and...

Embodiment 2

[0035] This example illustrates that the octane number of different types of catalytically cracked heavy-distillate gasoline can be increased by the method provided by the present invention. The tests were carried out in a medium-scale riser catalytic cracking unit.

[0036] Four kinds of catalytic cracking heavy distillate gasolines listed in Table 3, A, B, C and D, were respectively used as raw materials for the test, and catalyst C listed in Table 2 was used. The specific test steps were the same as in Example 1. The main reaction conditions, product distribution and main properties of gasoline products are listed in Table 5. It can be seen from Table 5 that no matter what type of FCC heavy gasoline, the octane number of FCC gasoline can be increased by 2-5 units by using the method provided by the present invention.

Embodiment 3

[0038] This example illustrates that various types of catalysts can be used in the present invention.

[0039] With gasoline A listed in Table 3 as raw material, three kinds of catalysts A, B and C listed in Table 2 were used to test, and the specific test steps were the same as in Example 1. The main reaction conditions, product distribution and main properties of gasoline products are listed in Table 6. As can be seen from Table 6, when catalyst A is used, the RON and MON of the product are 93.2 and 81.5 respectively, the olefin content is 8.8% by weight, and the sulfur content is 760ppm; when catalyst B is used, the RON and MON of the product are respectively 93.0 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com