External circulating ball screw self-lubricating module

A ball screw and external circulation technology, used in bearings, bearing components, combined bearings, etc., can solve the problems of shortening the effective stroke of the ball screw, wasting lubricating oil, lengthening the nut, etc., achieving good sealing, increasing service life, Avoid leaking effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

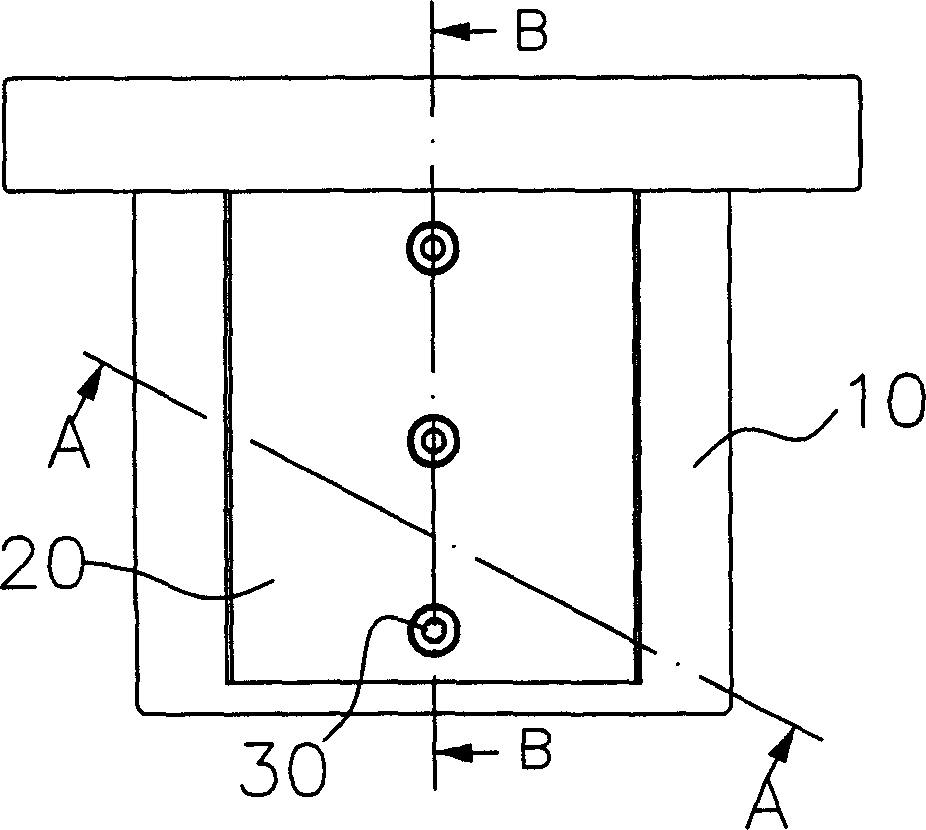

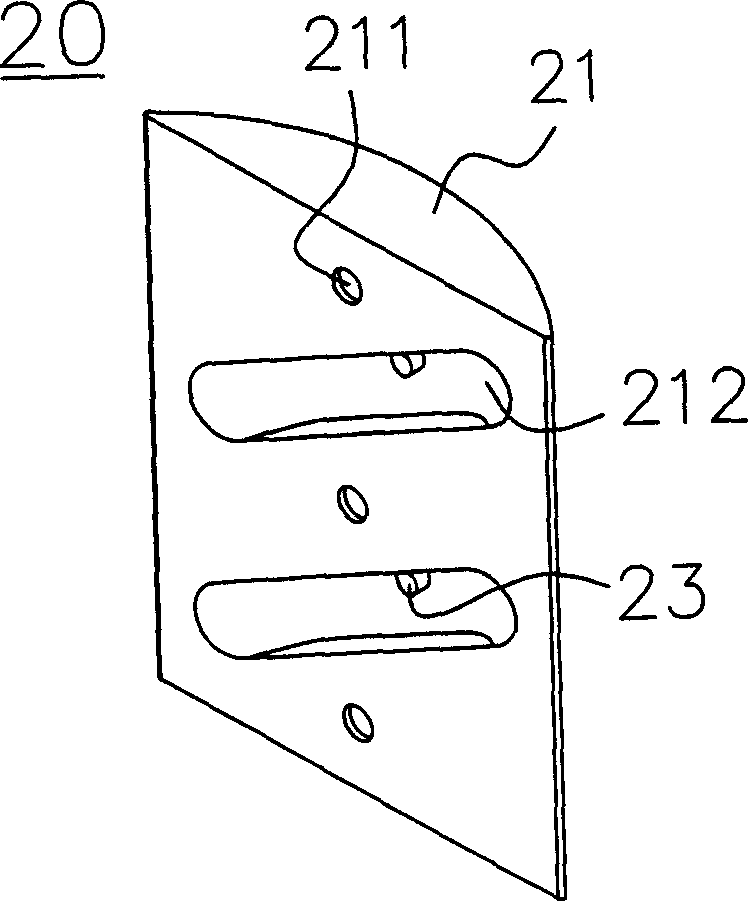

[0035] figure 1 It is the upper view of the nut of the exceptional circulation ball screw in this embodiment; wherein the self-lubricating module 20 of the present invention is arranged on the return system of the outer diameter of the nut 10, and the self-lubricating module 20 is provided with a bolt hole for installing the bolt 30, and The nut 10 is provided with matching screw holes, and the self-lubricating module 20 is fixed on the nut 10 by means of bolts 30 . figure 2 It is a three-dimensional schematic diagram of the self-lubricating module of this embodiment; the self-lubricating module 20 is mainly composed of an oil storage box 21 and an oil-containing material 23. The space in the oil storage box 21 is used to store lubricating oil, and there is a The bolt hole 211 that allows the bolt 30 to pass through and the groove 212 in the shape of the return system (not shown) that fits the nut. At the same time, there are holes in the groove 212 so that the oil-containin...

Embodiment 2

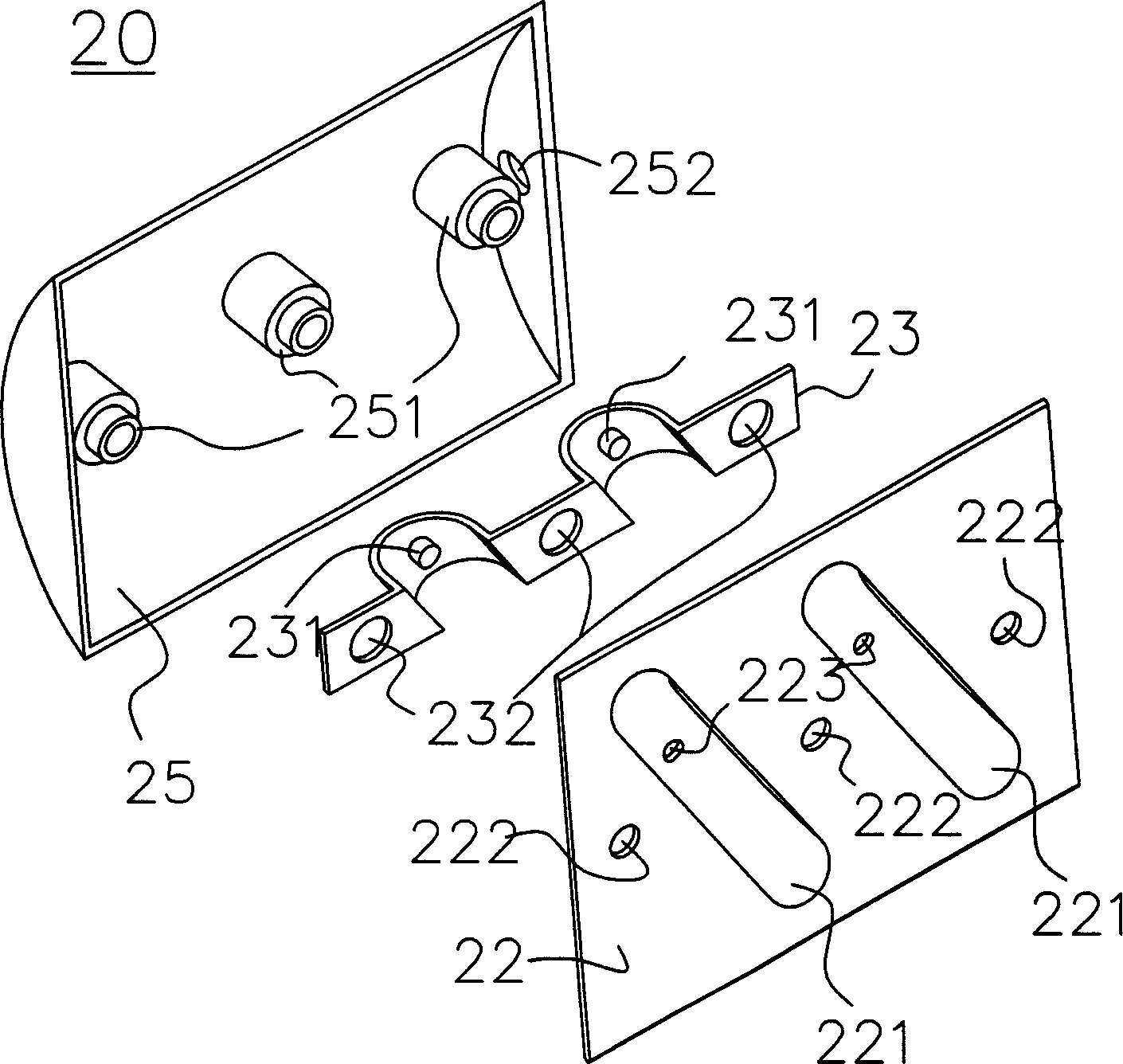

[0039] image 3 It is a three-dimensional exploded view of the self-lubricating module of this embodiment; the oil storage space of the self-lubricating module 20 is designed to be composed of two components, that is, the oil storage box is composed of an upper cover 25 and a lower cover 22, And an oil-containing material 23 is set in the oil storage space; a countersunk bolt hole 251 is provided in the upper cover 25 to provide a bolt (not shown) to pass through and screw lock, and an oil injection hole 252 is used to lubricate the self-lubricating module 20 Supplement; the outer side of the lower cover 22 is provided with a groove 221 and a bolt hole 222 matching the shape of the external circulation return system (not shown), and a lubrication hole 223 is pierced on the groove 221; the shape of the oil-containing material 23 conforms to the shape of the lower cover 22 The shape of the inner side of the lower cover 22 is placed on the inner side of the lower cover 22. The oi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com