Floor laying material, piece mat, and arranging structure thereof

A technology for arranging structures and floor mats, which is used in floor covering, thin material processing, other household appliances, etc., can solve the problems of high noise level, reduce the sound absorption performance of the cabin, and achieve the effect of reducing the noise level.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

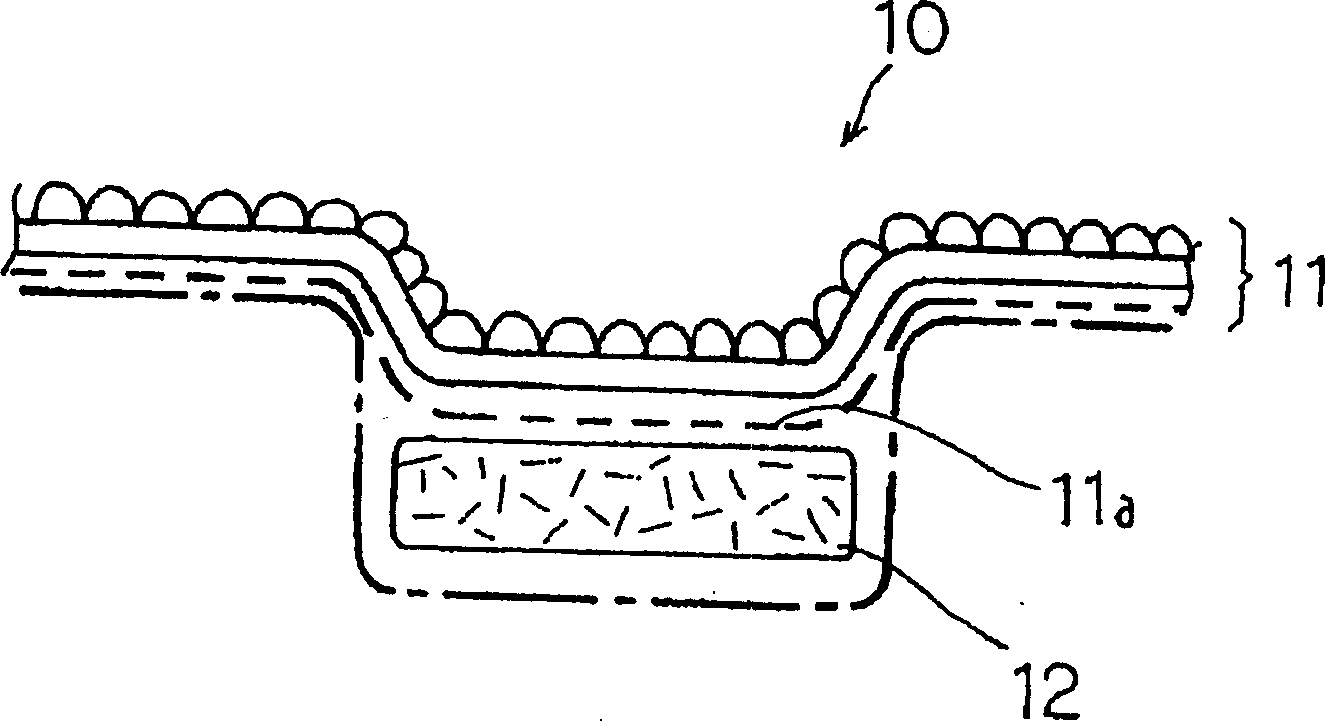

[0087] On the following permeable floor covering 10, the below-mentioned floor mat 20 is provided.

[0088] The floor covering material 10 used in the present example was made by the following process: at a flow resistance value of 400 Nsm -3 On the carpet-like layer 11 made of needle-punched carpet, the laminate thickness is 30mm and the density is 0.1g / cm 3 The cushioning material layer 12 made of polyester fiber felt is made.

[0089] In addition, the flow resistance value of the floor mat 20 used in this example is 100Nsm -3 , which is made by using 100g / m2 per unit area 2 The short fiber of dispersed polyethylene resin is formed as the adhesive layer of the bonding tape 23, and the per unit area is 100g / m 2 A layer 24 of cushioning material made of polyester resin non-woven fibers is laid on a support of 600g / m2 per unit area 2 On the base fabric layer 22 of the woven fleece layer 21, 120g / m per unit area 2 The back of the base fabric is a latex product (latex work) ...

example 2

[0091] On the same floor covering 10 as in Example 1, the following floor mat 20 was provided.

[0092] The flow resistance value of the floor mat 20 used in this example is 500Nsm -3 , which is made by using 150g / m per unit area 2 The short fiber of dispersing polyethylene resin is formed as the adhesive layer of bonding tape 23, will be per unit area 250g / m 2 A cushion material layer 24 made of polyester resin non-woven fibers is attached to a support of 600g / m2 per unit area 2 On the base fabric layer 22 of the woven fleece layer 21, 120g / m per unit area 2 A latex product with SBR (styrene-butadiene-rubber) resin coated on the back of the base fabric layer.

example 3

[0094] On the same floor covering 10 as in Example 1, the following floor mat 20 was provided.

[0095] The flow resistance value of the floor mat 20 used in this example is 1000Nsm -3 , which is made in the following way: by 350g / m 2 The short fiber of dispersing polyethylene resin is formed as the adhesive layer of bonding tape 23, will be per unit area 550g / m 2 A cushion material layer 24 made of polyester resin non-woven fibers is attached to a support of 600g / m2 per unit area 2 On the base fabric layer 22 of the woven fleece layer 21, 120g / m per unit area 2 A latex product with SBR (styrene-butadiene-rubber) resin coated on the back of the base fabric layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com