Trolley for moving building

A pulley and fixed seat technology, applied in building maintenance, construction, building construction, etc., can solve the problems of high work intensity, increased traction resistance, high cost, etc., and achieve the effect of high reuse rate, lower traction force, and steel saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

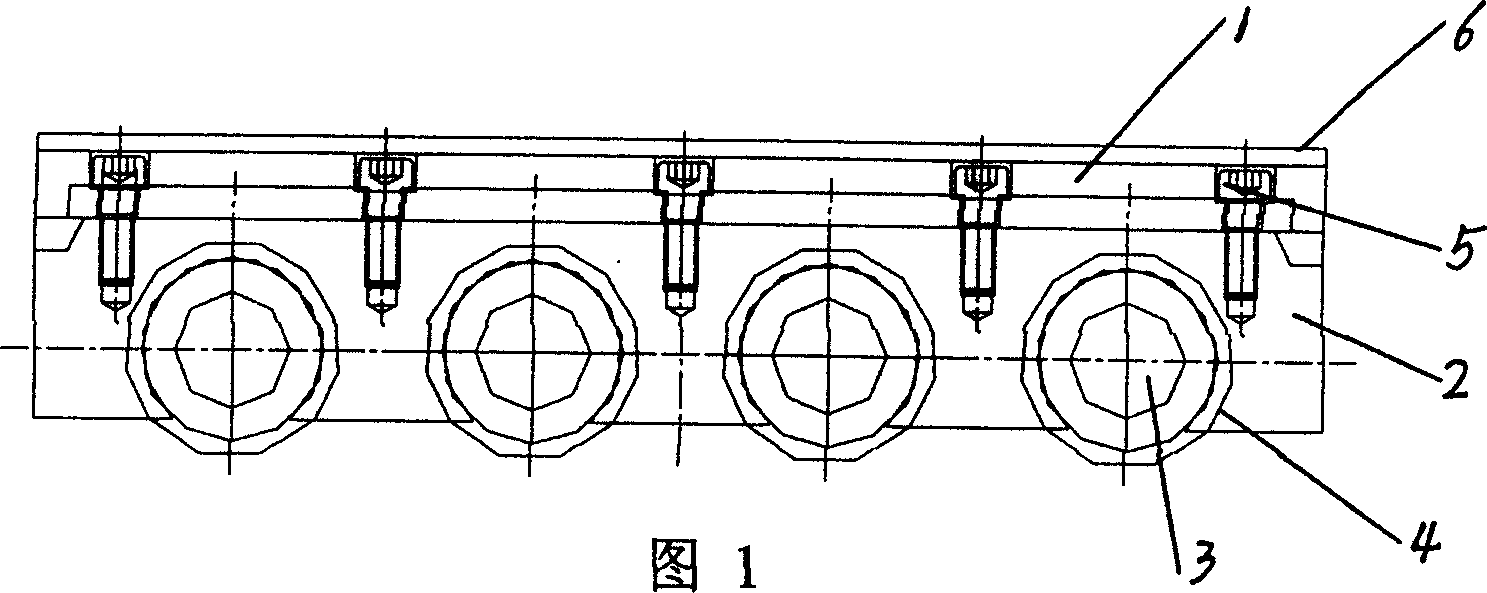

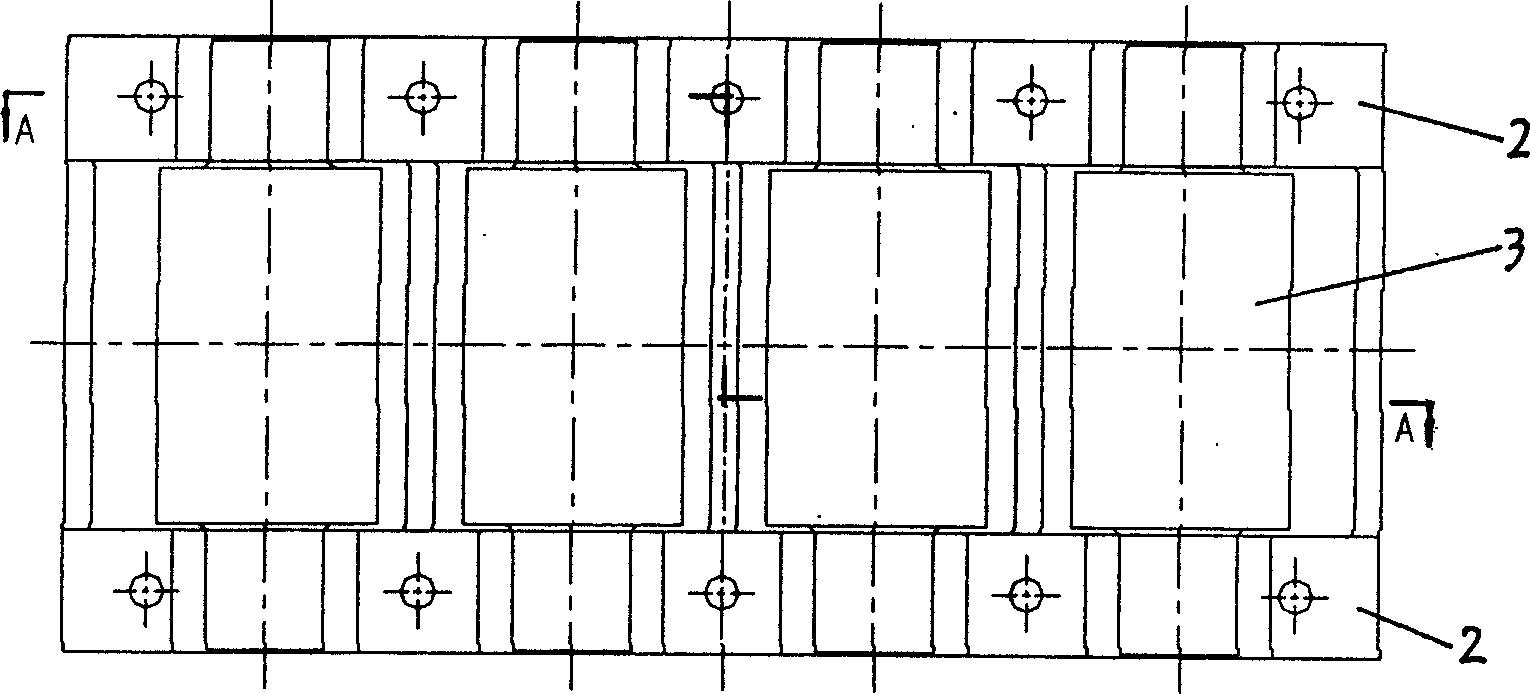

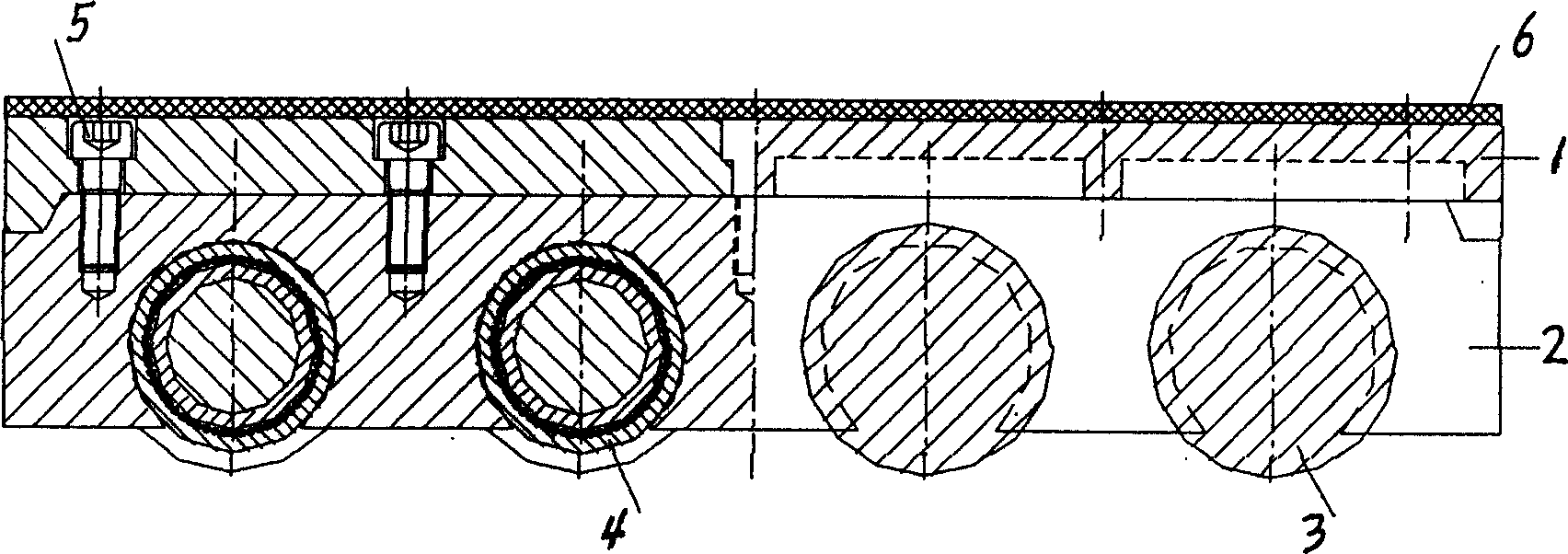

[0015] In Figure 1, figure 2 , image 3 In the structural schematic diagram of the present invention given, the fixing seat is composed of a top plate 1 and two side plates 2, and the side plates are fastened under the top plate with bolts 5 . Each roller 3 is installed between the side plates 2 through needle bearings 4 , and a rubber plate 6 is arranged on the top plate 1 .

[0016] exist Figure 4 , Figure 5 In the schematic diagram shown, the roller 3 of the building moving trolley 11 is in contact with the lower track 9, the upper track beam 8 is supported on the rubber plate 6 of the building moving trolley 11, and the weight of the translation building 7 is transmitted to the trolley 11 through the upper track beam 8 On the top plate 1, and finally passed to the lower track 9 by the pulley roller 3. As shown in the figure, when the building moves in translation, under the situation of adopting the building moving block of the present invention, the stress point of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com