Rotary damper device

A damper, viscous fluid technology, applied in the direction of shock absorbers, shock absorbers, liquid shock absorbers, etc., can solve the problems of low durability, difficult braking torque accuracy, and inability to obtain braking torque, so as to improve durability performance, load reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

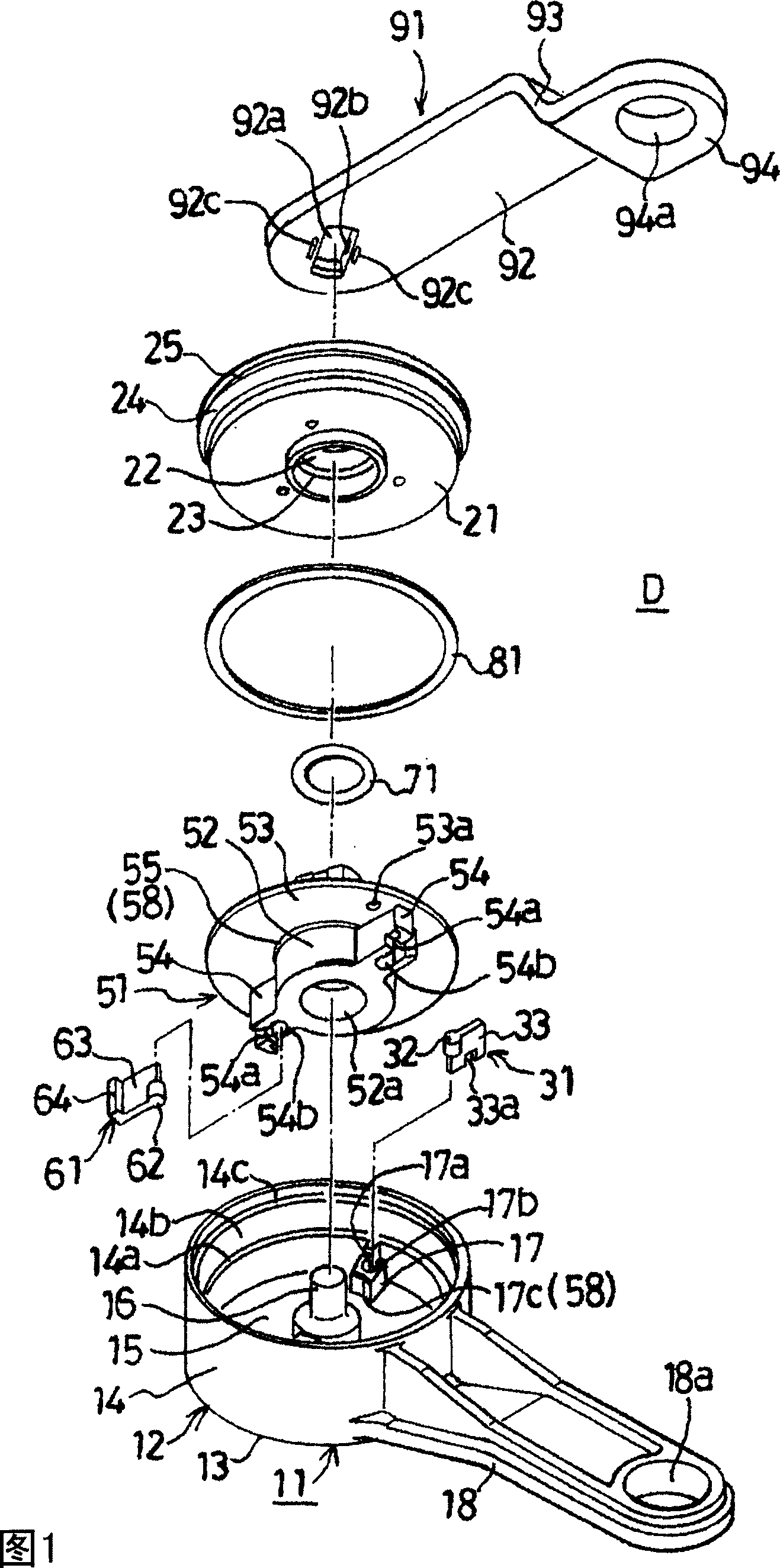

[0055] FIG. 1 is an exploded perspective view of a damper device according to an embodiment of the present invention.

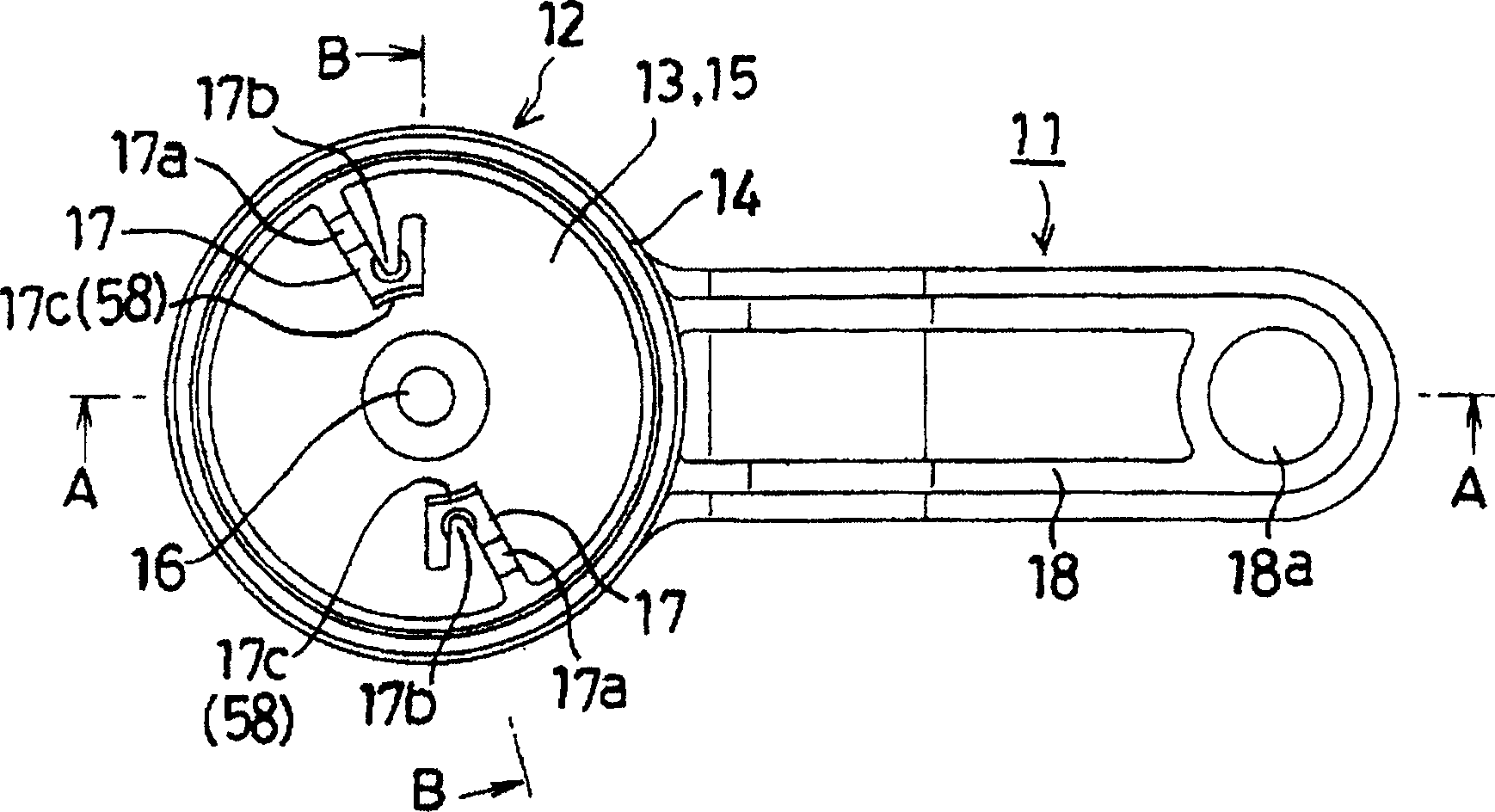

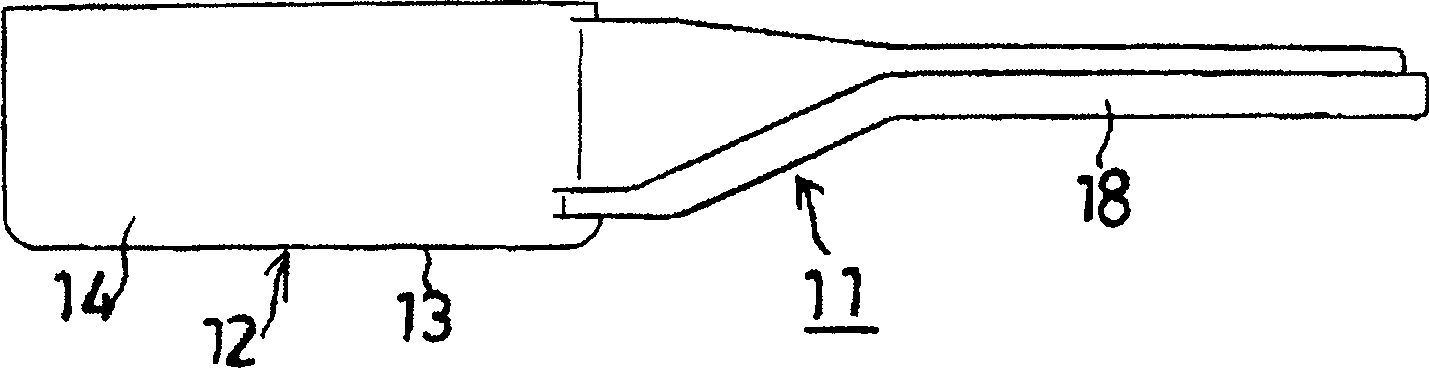

[0056] In Fig. 1, D represents the damper device, and is made up of the following parts: by having rigid synthetic resin such as the housing 11 that polycarbonate is made; For example, a cover 21 made of polycarbonate; a second valve 31 made of synthetic resin, such as polyacetal, installed on the second rotor wing at the bottom of the housing 11; viscous fluid silicone oil 41 in the casing 11 (accommodation portion 15); rotatably installed in the casing 11, having a part of the shaft portion 52 protruding from the through hole 22 of the cover 21 to the outside, made of synthetic resin such as polycondensation Rotor 51 made of aldehyde; Installed on the first rotating wing 54 on this rotor 51, is made of non-swellability to viscous liquid such as sili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com