Mass flow characteristic testing device for coolant of liquid-cyclic throttle mechanism

A technology of throttling mechanism and characteristic testing, applied in the direction of mass flow measurement device, indirect mass flowmeter, etc., can solve the problem of not eliminating nitrogen test flow error, etc., and achieve significant social and economic benefits, easy to control, and easy working conditions. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

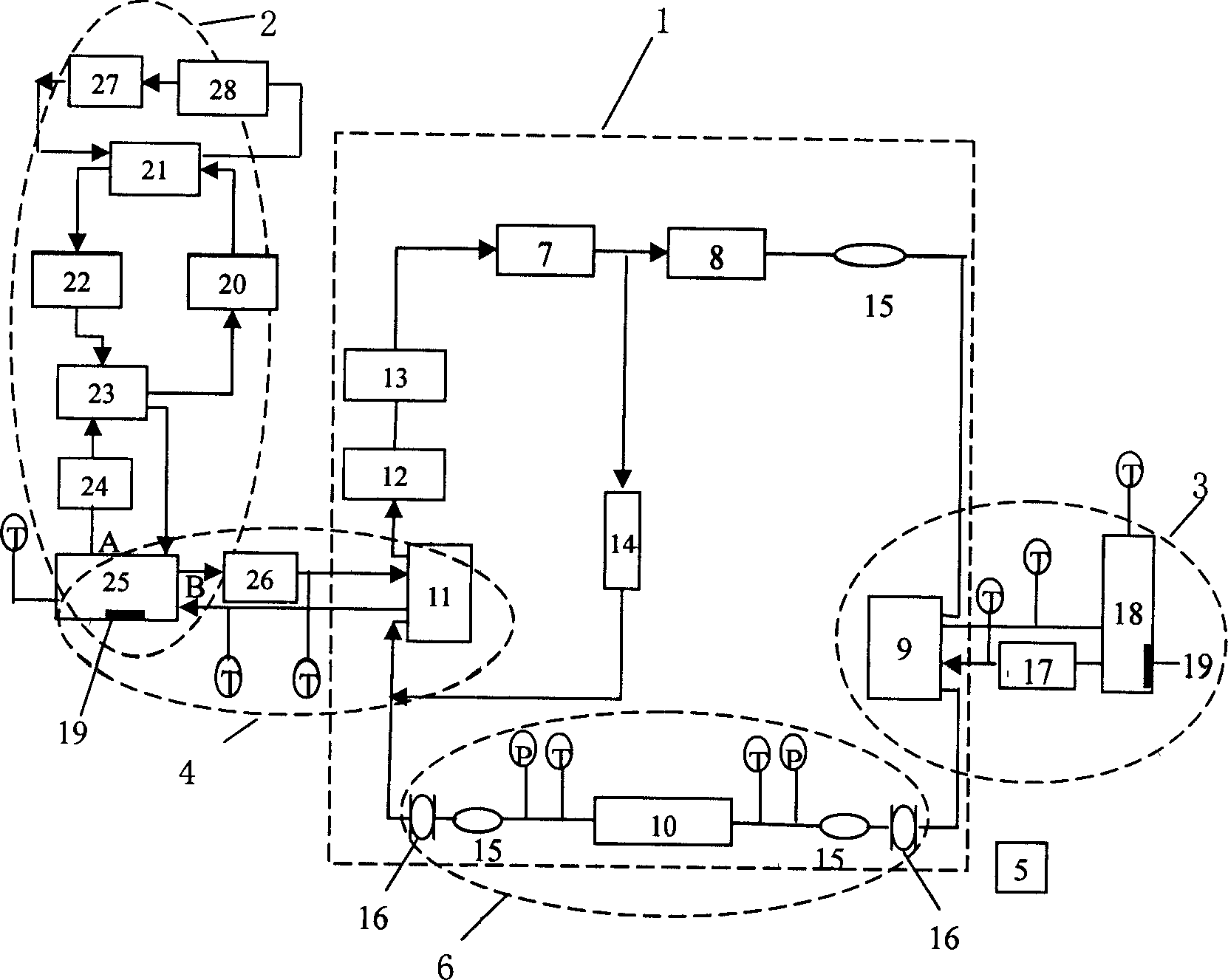

[0014] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

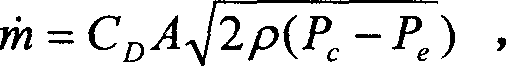

[0015] Such as figure 1As shown, the present invention includes a main circuit 1 , a refrigeration circuit 2 , a hot water circulation circuit 3 , an ethylene glycol solution circulation circuit 4 , and an operation console 5 . The main circuit 1 is the core component of the flow characteristic test device, which consists of a magnetic pump 7, a mass flow meter 8, a refrigerant flow path of a high-pressure heat exchanger 9, a test section 6, a refrigerant flow path of a low-pressure heat exchanger 11, and a storage tank. Liquid container 12, filter 13, bypass valve 14 is composed. The test section 6 includes a throttling mechanism 10 to be tested, a sight glass 15 arranged at both ends of the throttle mechanism 10 to be tested, and a ball valve 16 arranged at the inlet and outlet of the test section 6. The main circuit 1 passes through a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com