Solar energy three-dimensional concentrating collector

A technology of concentrators and heat collectors, applied in the field of solar thermal energy utilization, can solve problems such as inability to be commercialized, and achieve the effects of low cost, reduced cost, and reduced processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

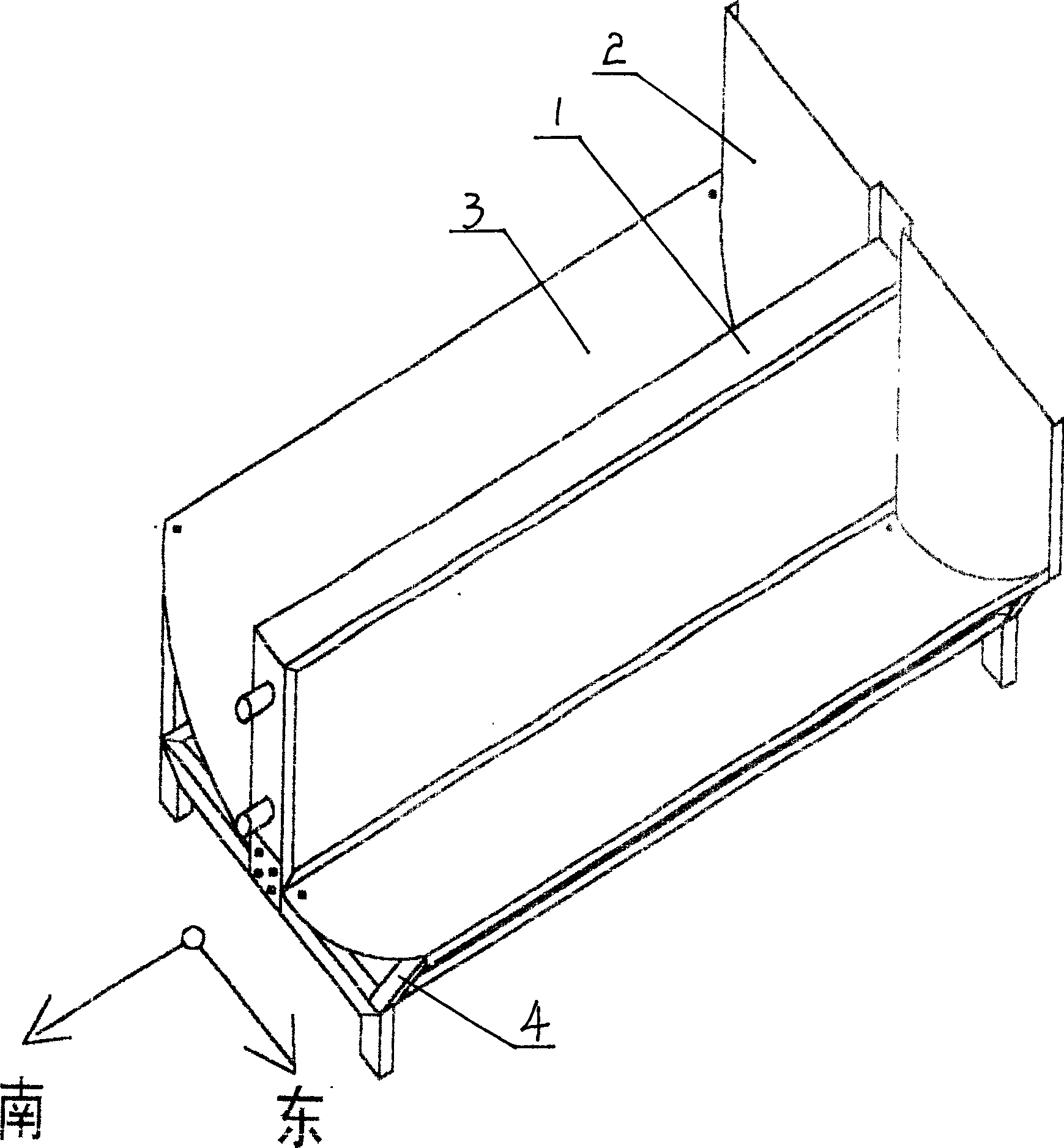

[0015] see figure 1 , this embodiment is a curved-plane concentrator, that is, the horizontal concentrator adopts a curved form, and the vertical concentrator adopts a planar form. It consists of a heat absorbing body 1, a vertical focusing disc 2, a horizontal focusing disc 3, a mold base 4 and connectors. The best solution for heat absorbing body 1 is to use a heat collecting box with glass on both sides and an insulating layer on the frame; the plate core is made in the form of a flat plate collector; Type focusing disc 3 is consistent, its height is one time of horizontal focusing disc 3 heights, and width gets 8cm. The mold base 4 is to determine the model support of the translational paraboloid of the horizontal focusing disc 3, and the horizontal focusing disc 3 is equipped with two mold bases before and after. Formwork 4 is made with reference to several points of the parabola, and the reference parabola is x 2 =100y, get the line segment below its focal plane as th...

Embodiment 2

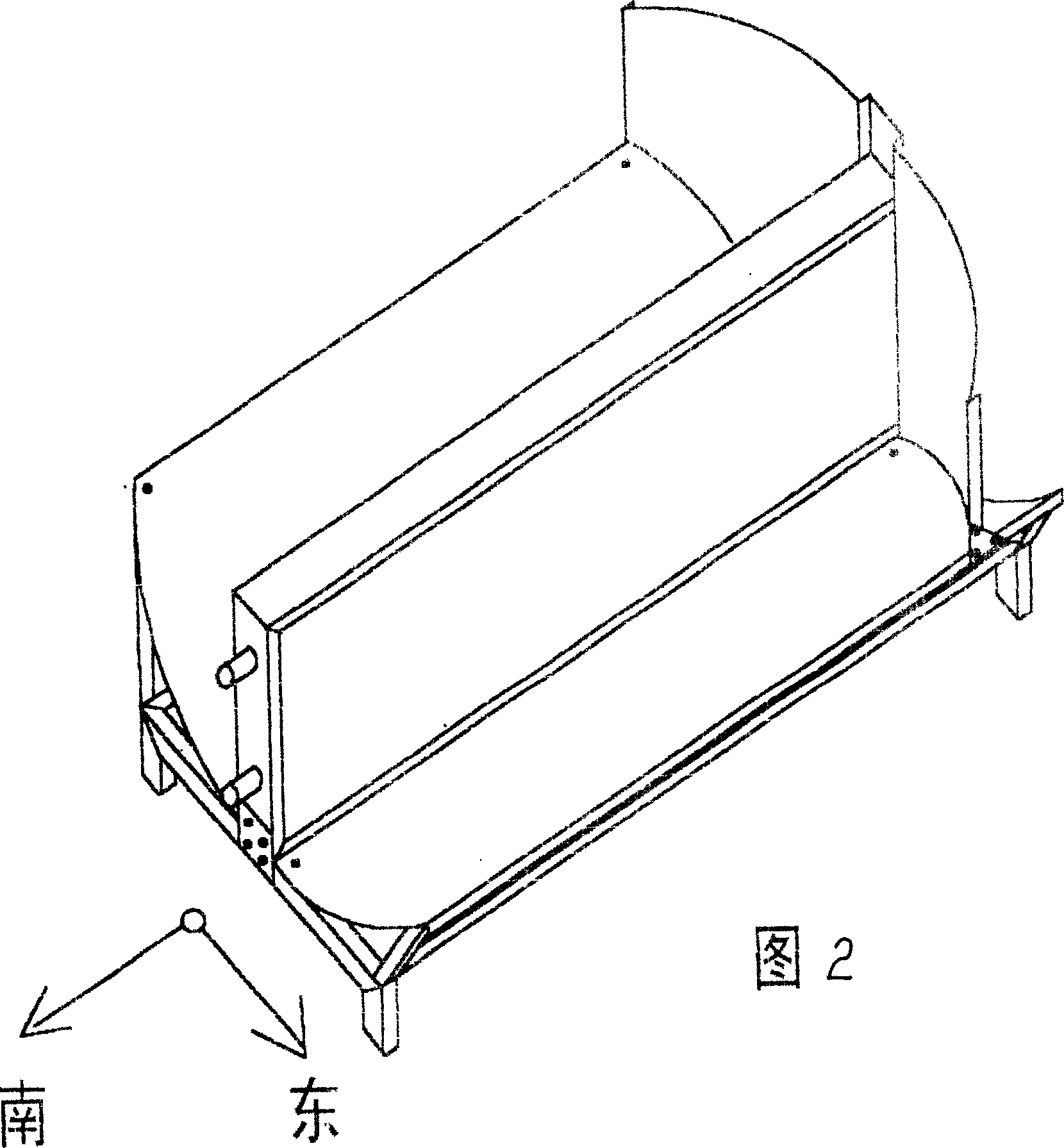

[0017] Referring to Fig. 2, this embodiment is a hyperboloid concentrator, that is, both the horizontal concentrator and the vertical concentrator are curved. It is also composed of a heat absorber, a vertical concentrator, a horizontal concentrator, a mold base and connectors. The manufacturing method and structure are the same as those in the embodiment. In order to increase the heat collection effect, its vertical concentrator adopts a translational parabolic surface structure, and the lower part of the vertical concentrator is processed into a curve corresponding to that of the horizontal concentrator. The two concentrators are connected by a triangular joint.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com