Driving system for rotary tools in a tool holder turret

A drive system, a technology for rotating tools, applied in drive devices, mechanical drive clutches, manufacturing tools, etc., can solve problems such as jeopardizing the accuracy of the turret, complex crown assembly systems, and difficult modularization of the rotary tool rest table.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

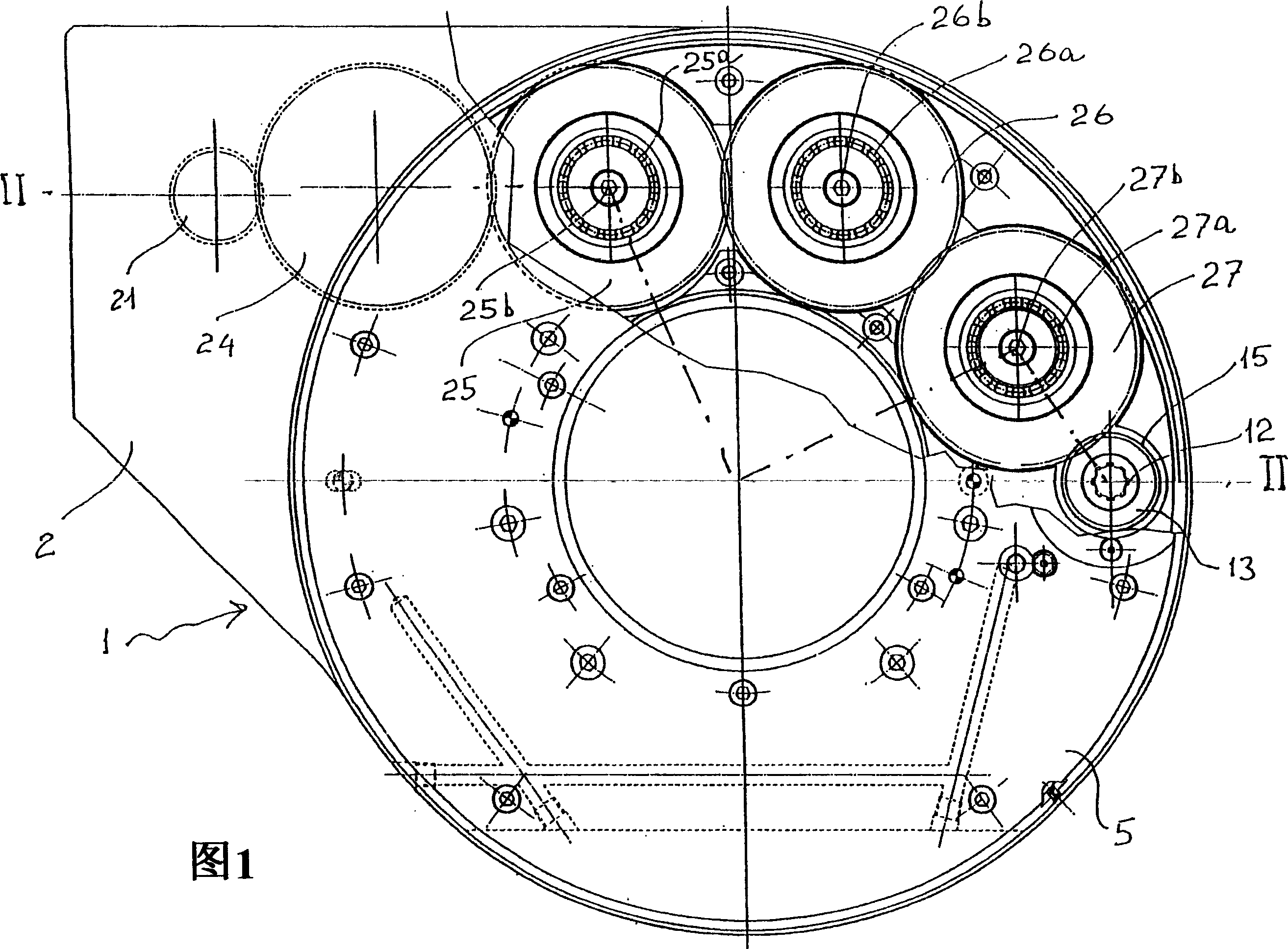

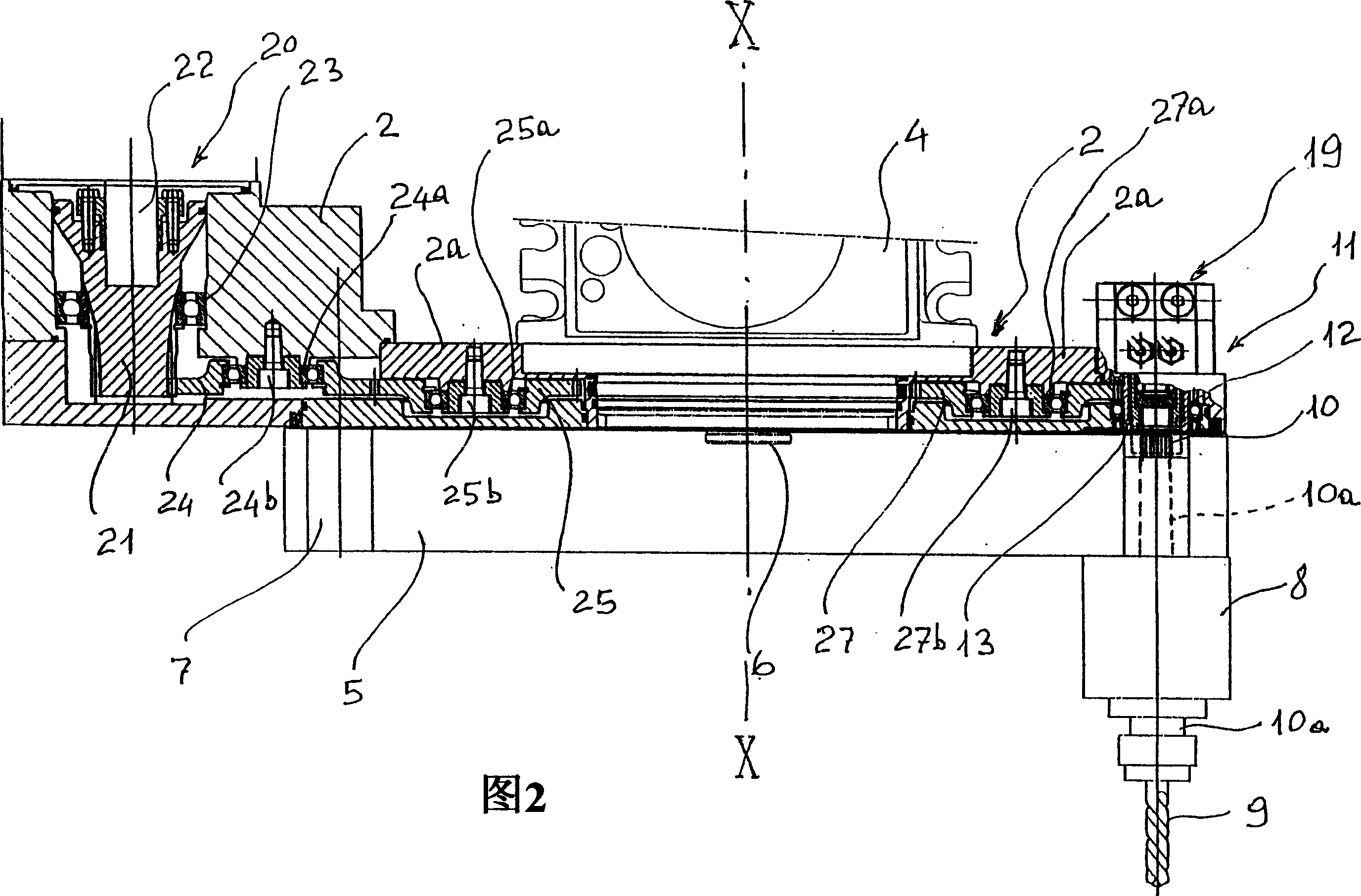

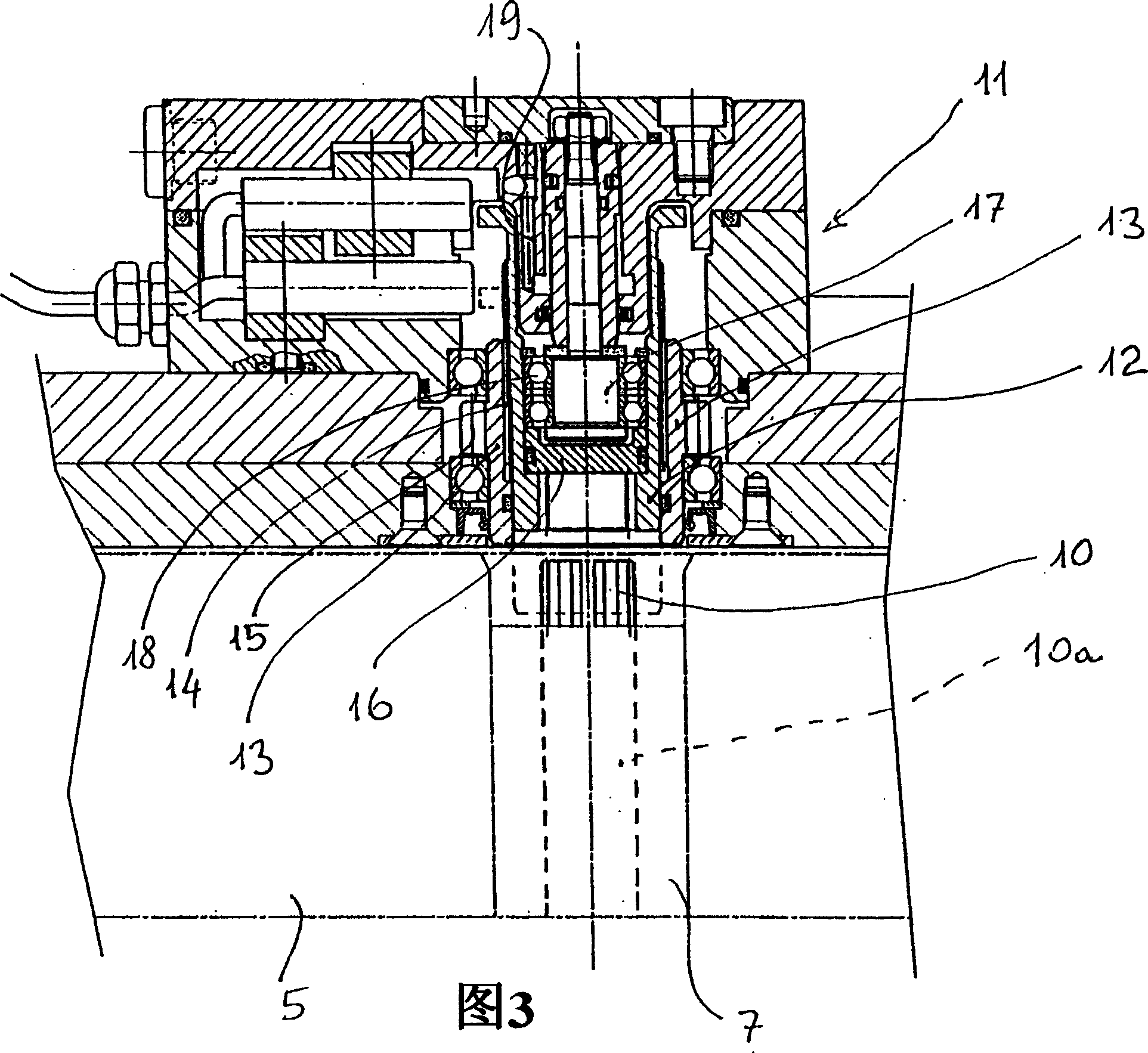

[0019] With reference to the aforementioned drawings, the tool holder worktable, especially the worktable for mounting the rotary drill bit and the boring tool, is generally represented by 1.

[0020] The stationary part of the workbench includes a main body 2 with a cavity 3 extending around the longitudinal axis X-X; the main body 2 is designed to be connected to the fixed part 4 of a conventional turret partially shown in the figure.

[0021] The rotating part of the worktable is denoted by 5, which is connected with the rotating part of the turret denoted by shaft 6. The axis of the shaft 6 coincides with the axis XX to change the angle of the working position of the tool around the axis XX The displacement occurs in a conventional manner.

[0022] On the rotating part 5, a bracket 7 for the mandrel 8 is formed in a circumferential area, such as a rotating tool indicated by 9 in the drawing, fixed therein.

[0023] In these conventional mandrels 8, the shafts of their respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com