Method and device for producing coking briquette by using waste residue from coke plant

A technology for production equipment and tar waste residue, which is applied in the petroleum industry, solid fuel, fuel and other directions, can solve the problems of burning down the motor, deteriorate the operating environment, waste labor, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

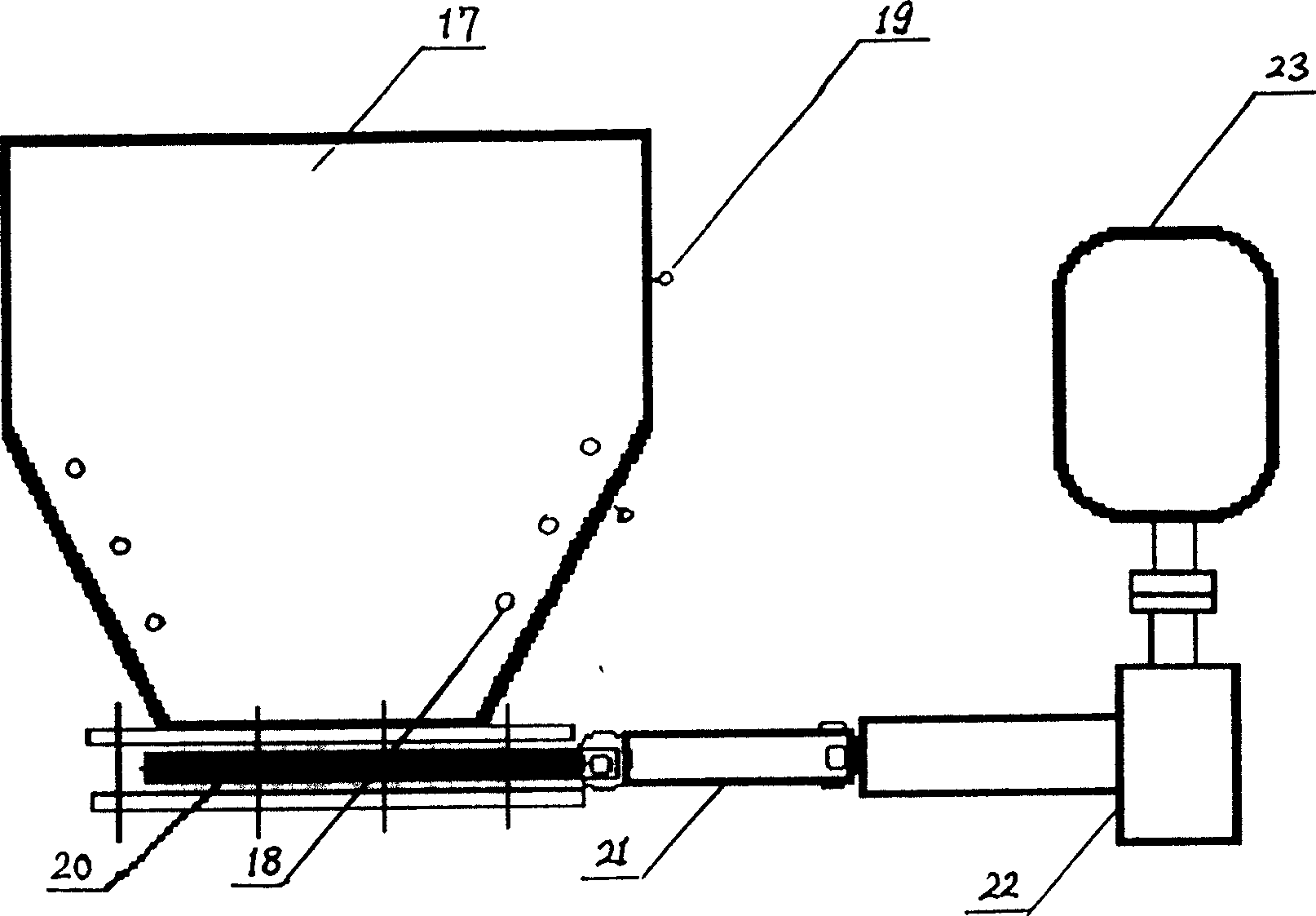

[0015] The binder in the briquette formula is the tar waste residue produced after coking in the coking plant. The composition of binder tar residue and the binder tar residue consumption are shown in the following table (content %):

[0016]

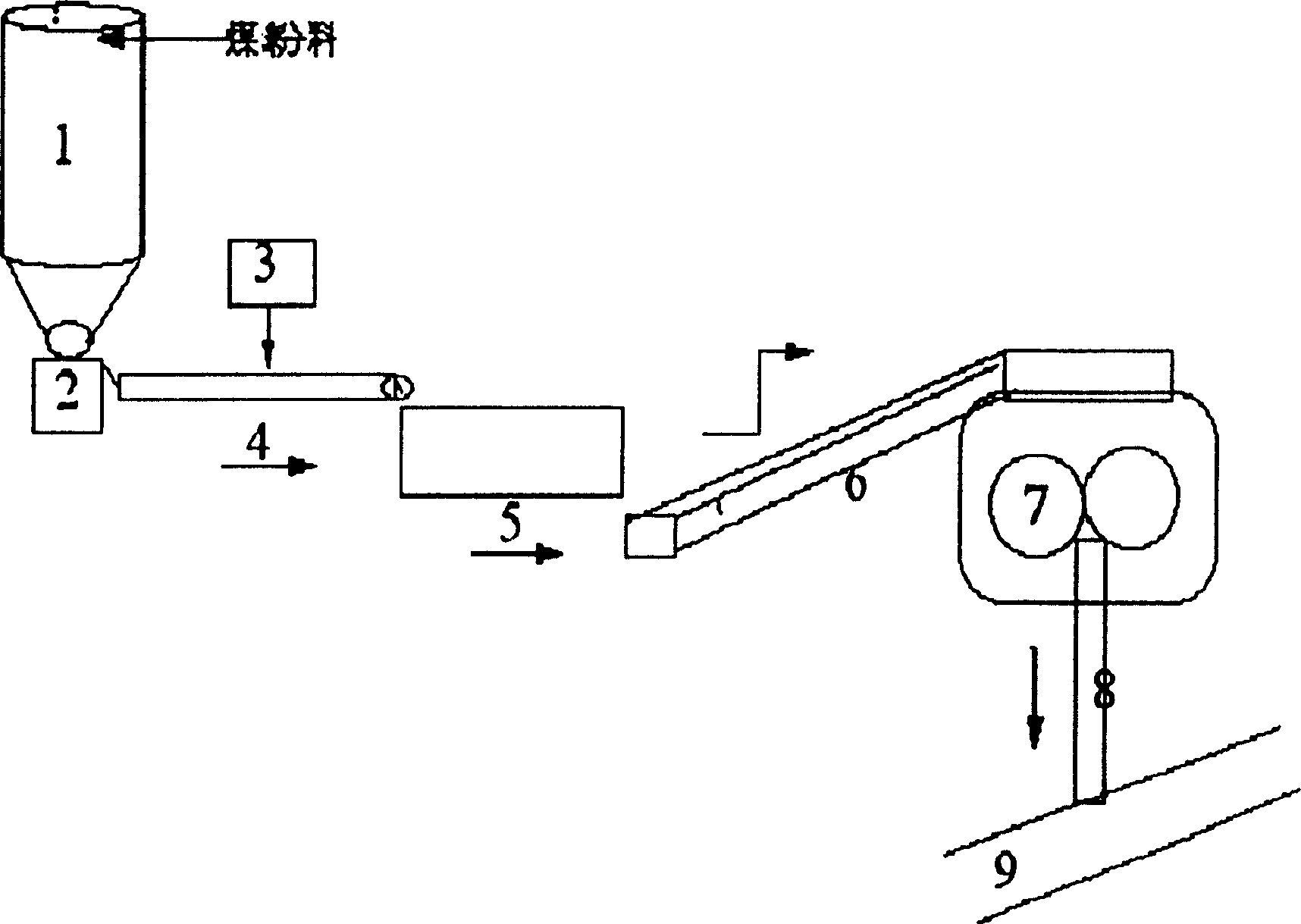

[0017] 1. The technological process of briquette production is as follows: the electromechanically controlled feeder intercepts the crushed coal (with a particle size of 3-5mm) from the belt conveyor 6 and enters the briquette raw material tank 1 (in this way, it can be directly used In the coal preparation process, the coal material after the crusher is saved, and the crushing equipment in this process is omitted), and the coal material is batched by the disc feeder 2 (the disc feeder is used for batching, which is easy to control the raw coal and binder Proportioning), then transported to the kneader 5 through the belt conveyor 4, the kneader 5 is to use a biaxial screw mixer to mix and knead the coal and tar residue; the tar resid...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap