Cotton mill air-conditioning dust collection automatic control system

An automatic control system, a technology for cotton spinning mills, applied in heating and ventilation control systems, heating and ventilation safety systems, space heating and ventilation, etc., can solve problems such as difficulty in opening workshop equipment, increased labor costs, and energy waste. The effect of improving the quality of finished and semi-finished products, good economic benefits, and extensive social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

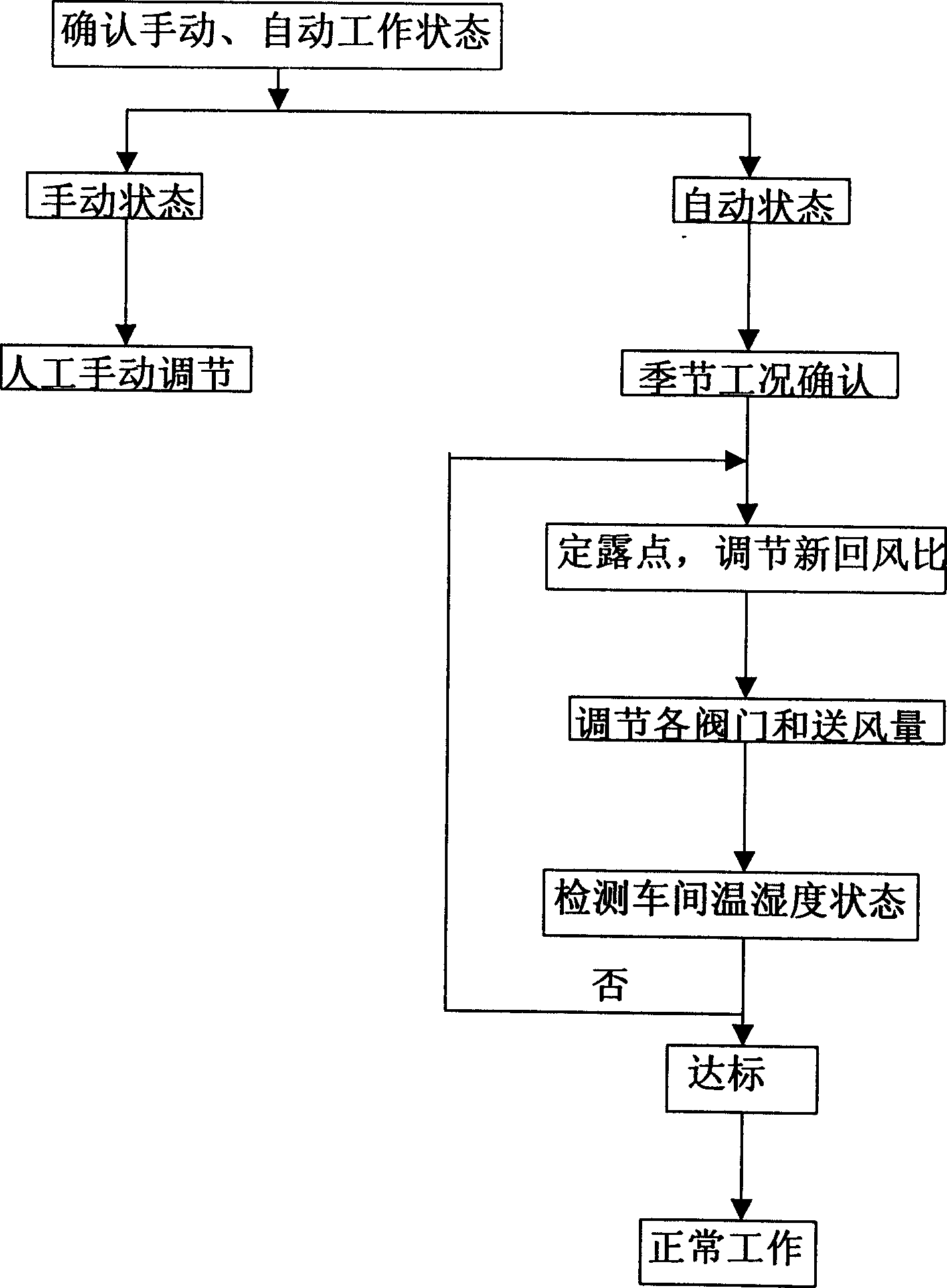

[0013] The air-conditioning and dust removal automatic control system of the cotton spinning mill according to the present invention comprises a pipe connecting the controlled workshop of the cotton spinning mill and the air-conditioning room; room, circulating water pump, steam humidifier, air blower, and air supply regulating valve, and a differential pressure controller is installed on the return air filter; temperature and humidity sensors are installed in the controlled workshop; There are temperature and humidity sensors and enthalpy transmitters; air valve electric actuators are installed on the air supply valve, return air valve, and fresh air valve in the air conditioning room; electric valves are installed on the water supply pipeline and steam pipeline in the air conditioning room; The air volume of the sending and returning fans is controlled by a frequency converter; a dew point temperature sensor is set after the spray section of the spray room; a direct digital c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com