Rare-earth oxide secondary emitting material and method for preparing same

A technology of rare earth oxides and emission materials, applied in the fields of rare earth metal compounds, chemical instruments and methods, inorganic chemistry, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

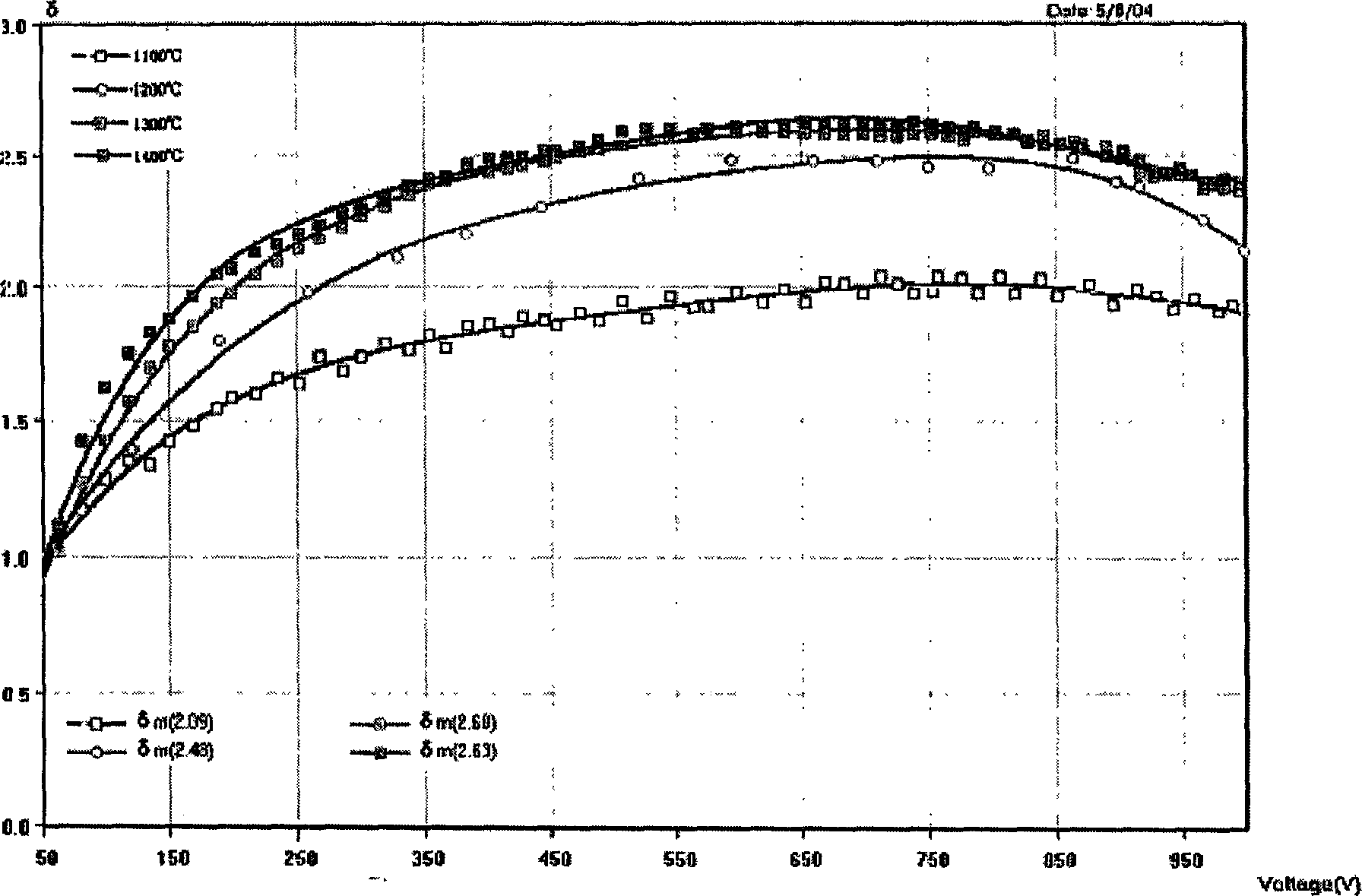

[0014] Example 1. Take La 2 O 3 The powder is a precursor, mixed with cotton gum, ethyl oxalate, and methanol, and ball milled for 60 hours, with a ball-to-material ratio of 300:80. Then mix with nitrocellulose and nitrocellulose to make a suspension. The suspension is immersed in the Mo sponge layer attached to the metal Mo sheet, the thickness of the sponge layer is 180 μm, the particle size of the powder used in the sponge layer is 40-60 μm, and the pore size is 40%. Dry it in an oven and sinter it under a hydrogen atmosphere to make La 2 O 3 - Mo spongy cathode, then made into a magnetron after degassing and activation treatment. The secondary emission coefficients tested at 600°C after different activation temperatures are determined by standard methods, see figure 1 , the life test data are shown in Table 1.

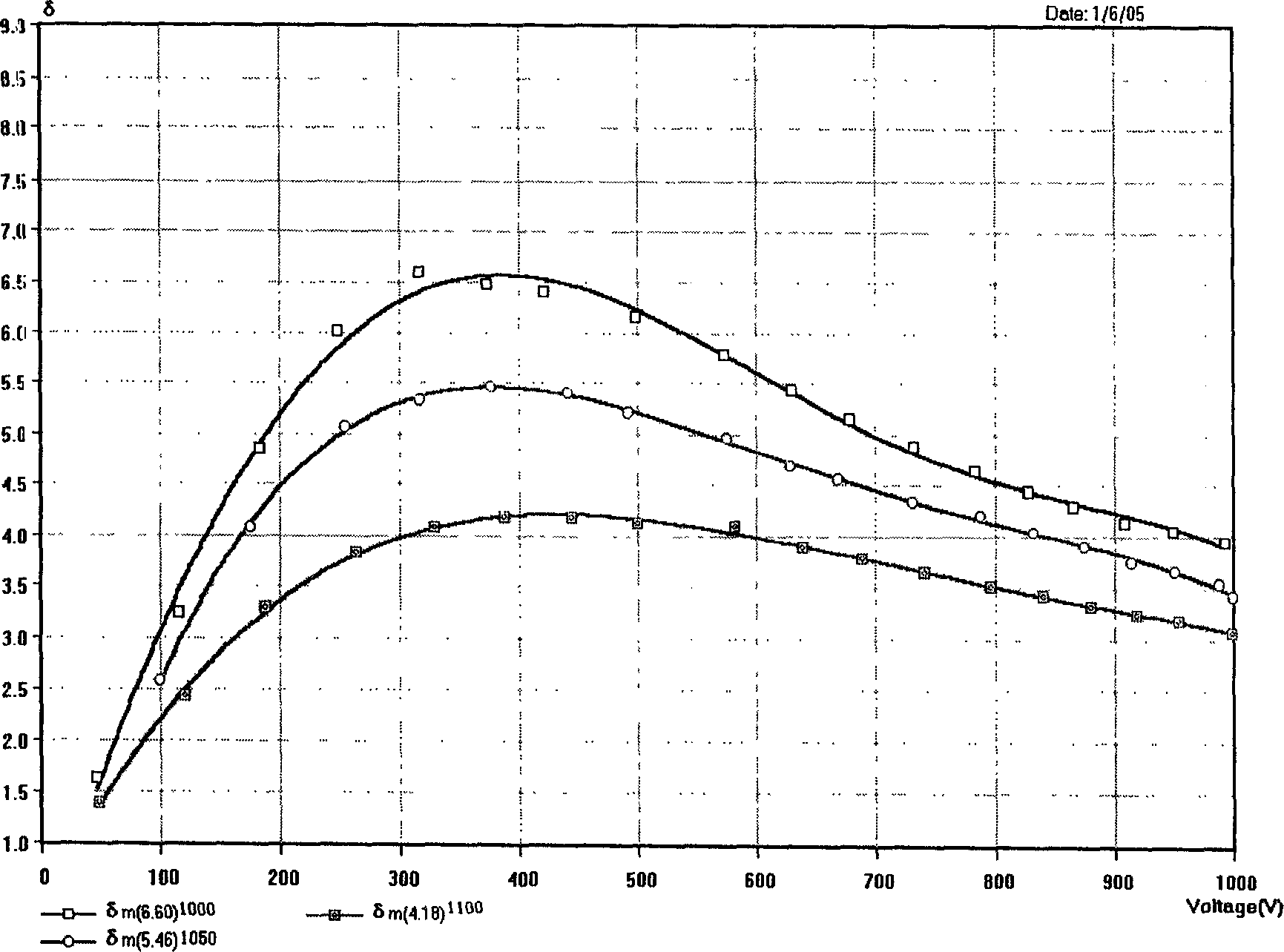

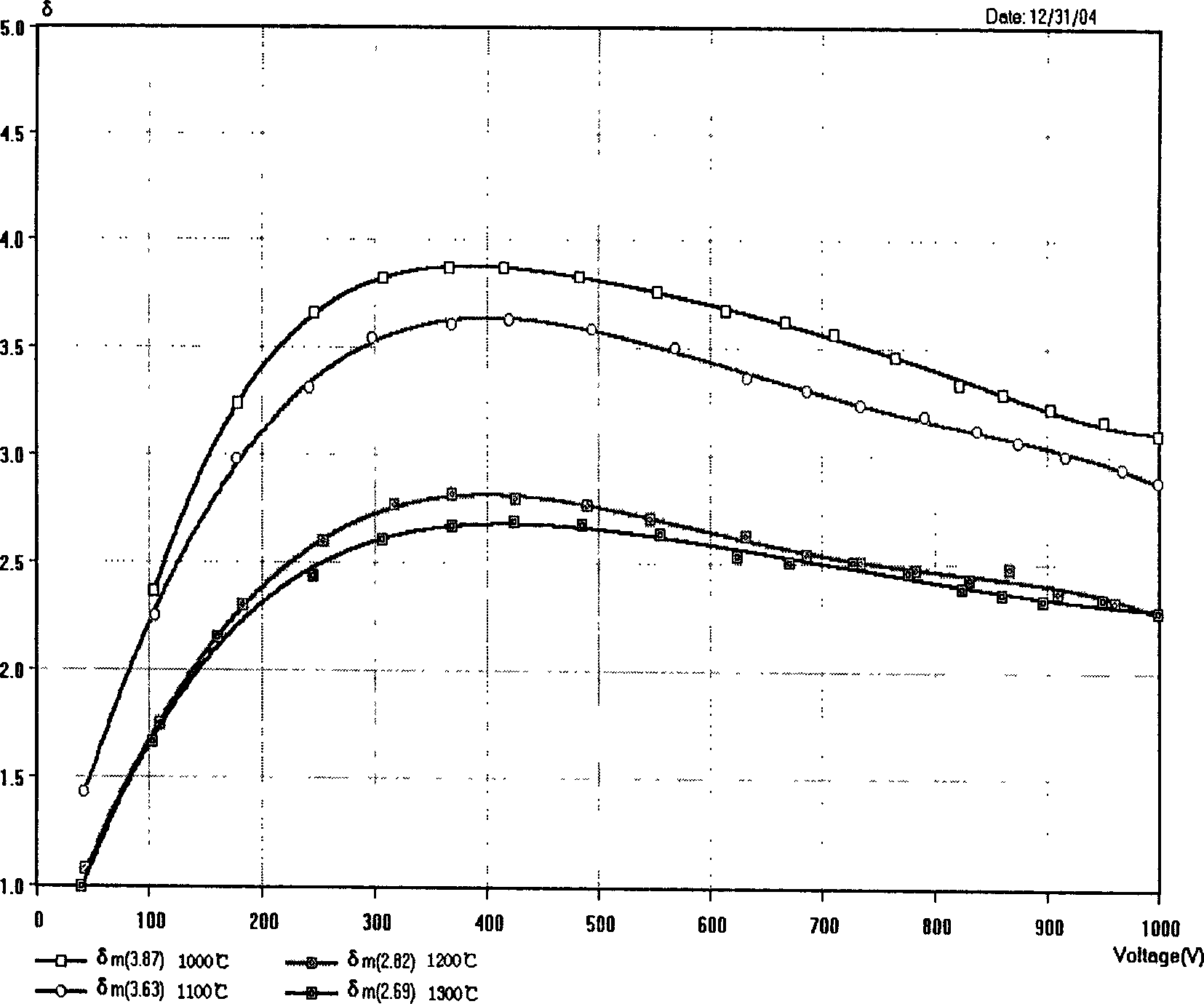

[0015] Example 2. Take Y 2 O 3 The powder is a precursor, mixed with cotton gum, ethyl oxalate, and methanol, and ball-milled for 60 hours with a ball-to-m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com