Composite method of making honeycomb material by pipe

A technology of honeycomb materials and pipes, which is applied in the direction of cardboard articles, etc., can solve the problems of lack of versatility, inability to pull apart, product specification restrictions, etc., to ensure composite strength and overall quality, ensure uniform glue coating, and simple production methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1: The making of paper honeycomb material.

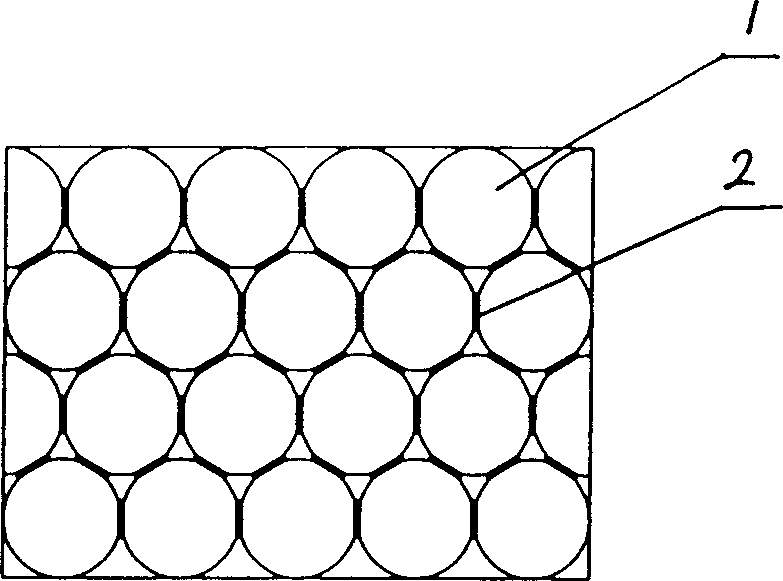

[0018] Such as figure 1 , paper tubes 1 arranged in the same direction are bonded together by adhesive 2 to form a honeycomb composite body, the length of the paper tube can be relatively long, and the thickness of the honeycomb core material is obtained by longitudinally cutting the honeycomb composite body to obtain the required size, and the edge Cut flush. Honeycomb materials of the same size can be spliced to form a honeycomb body of a larger size.

[0019] According to the method of the present invention, the adhesive adopts the impregnated glue whose weight ratio of starch and water is 1:3-8. The drying and curing strength is 30-80°C, and natural sunlight can be used in summer.

Embodiment 2

[0020] Embodiment 2: The making of metal honeycomb material.

[0021] Such as figure 1 , the metal aluminum pipes 1 arranged in the same direction are bonded together by an adhesive 2 to form a honeycomb composite. The thickness of the honeycomb material is obtained by cutting the honeycomb composite longitudinally to obtain the required size, and the edges are cut flush. When using metal aluminum tubes to make honeycomb materials, the surface of the aluminum tubes should be pretreated to remove dirt, grease and other anti-sticking substances. According to the method of the present invention, the adhesive adopts a single-component epoxy resin glue solution.

Embodiment 3

[0023] Such as figure 1 , PVC pipes 1 arranged in the same direction are bonded together by an adhesive 2 to form a honeycomb composite. The thickness of the honeycomb material is obtained by cutting the honeycomb composite longitudinally to obtain the required size, and the edges are cut flush. According to the method of the present invention, the adhesive used is composed of methyl ethyl ketone and PVC resin material, methyl ethyl ketone: PVC resin material=80:20 (weight ratio).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com