Dismountable combined particle filling machine

A combined, filling machine technology, applied in loading/unloading, transportation and packaging, chemical instruments and methods, etc., can solve problems such as slow speed, non-disassembly, and rework

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

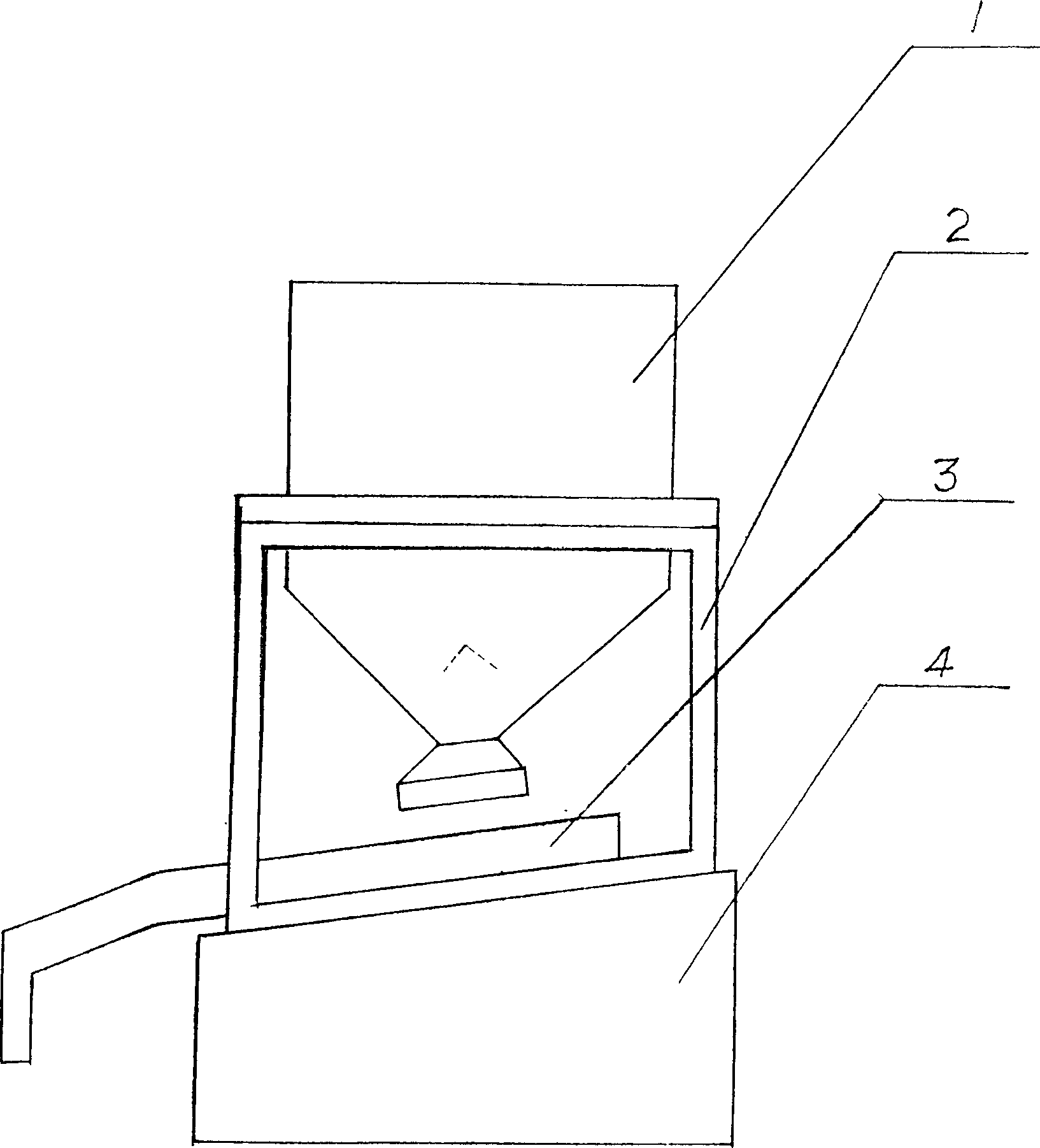

[0020] Such as figure 1 As shown, the present invention discloses a detachable combined particle filling machine, which includes: a hopper 1 and a material conveyor 3, and the granular material loaded into the hopper 1 is transported by the material conveyor 3 Into the target place, wherein, the hopper 1 is supported above a base 4 by a bracket 2, the material conveyor 3 is located on the base 4 and below the discharge port 10 of the hopper 1, the material conveyor 3 can be placed on a Driven by the power transmission system, it reciprocates on the base 4 .

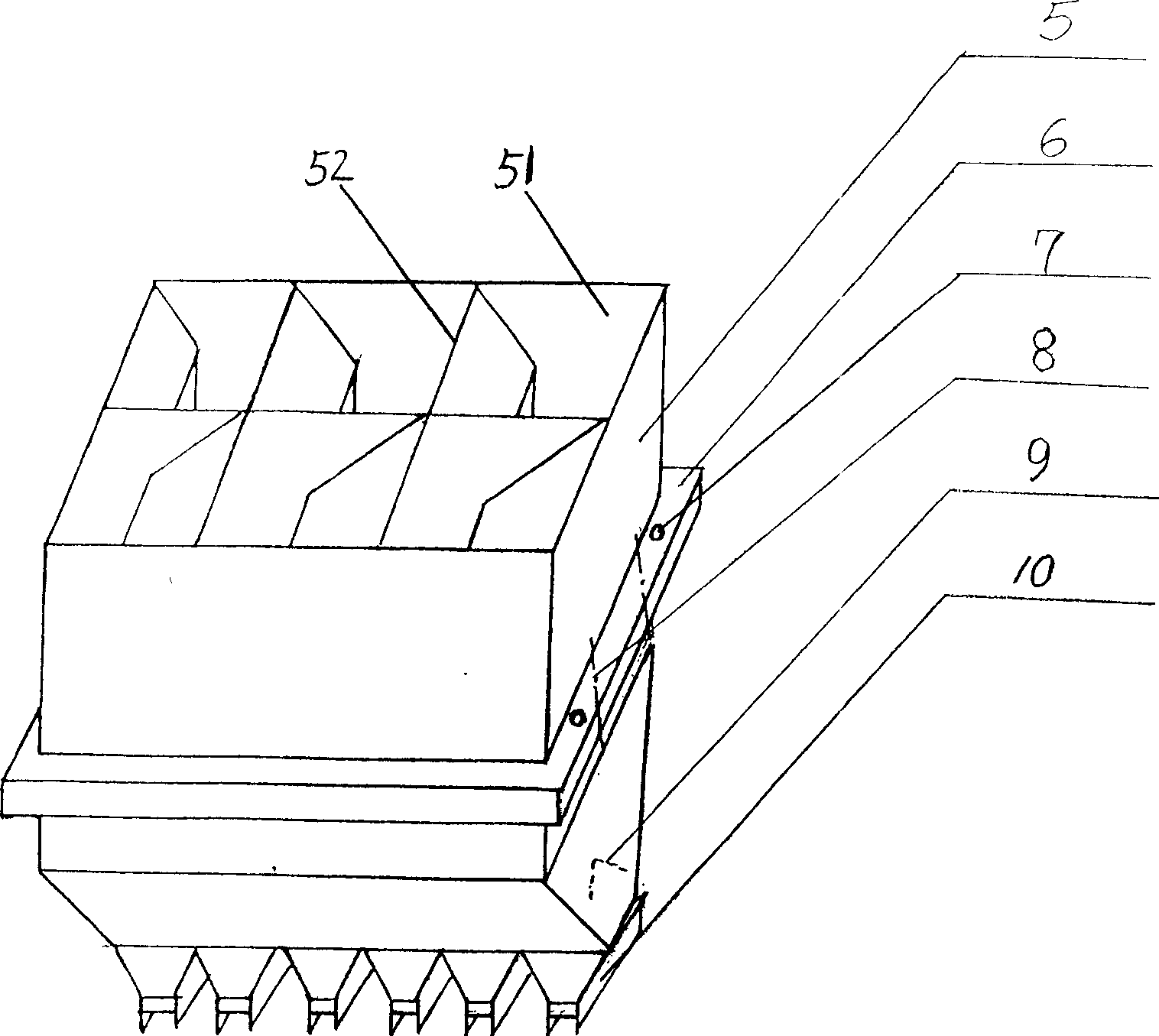

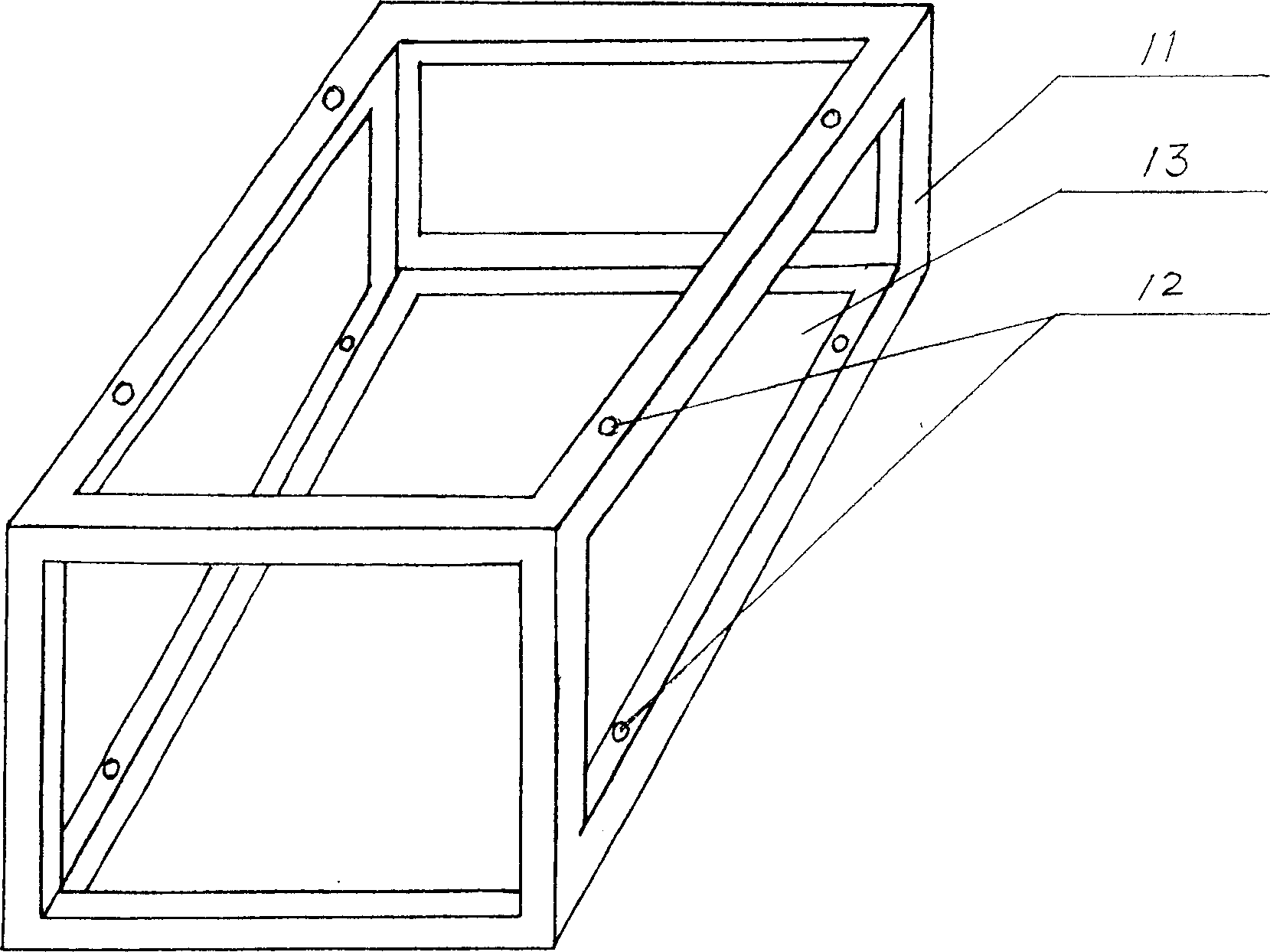

[0021] According to an embodiment of the present invention, such as Figure 4 and 5 As shown, the base 4 is provided with a guide groove 21, and the corresponding position on the material conveyor 3 is provided with a slider 17. 21, so that the material conveyor 3 reciprocates on the base 4. The guide slots 21 can be arranged on both sides of the base 4 , and the sliders 17 are correspondingly arranged on both sides o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com