Electrostatic chuck, substrate support, clamp and electrode structure and producing method thereof

An electrostatic chuck and substrate technology, which is applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., can solve problems such as uneven plasma density, plasma cannot be uniformly generated, and electrode temperature increases.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

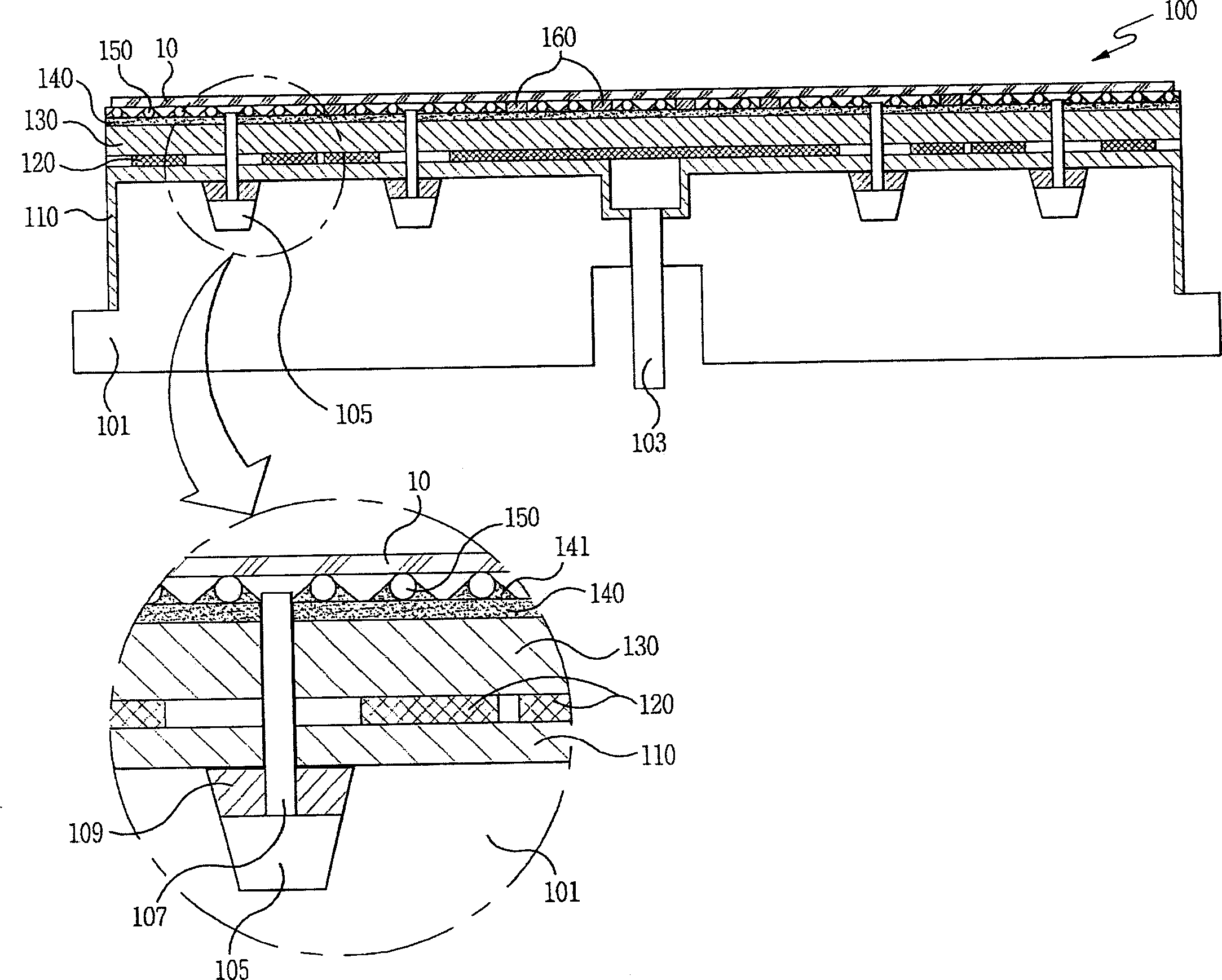

[0037] Preferred embodiments of the present invention will be described below with reference to the accompanying drawings.

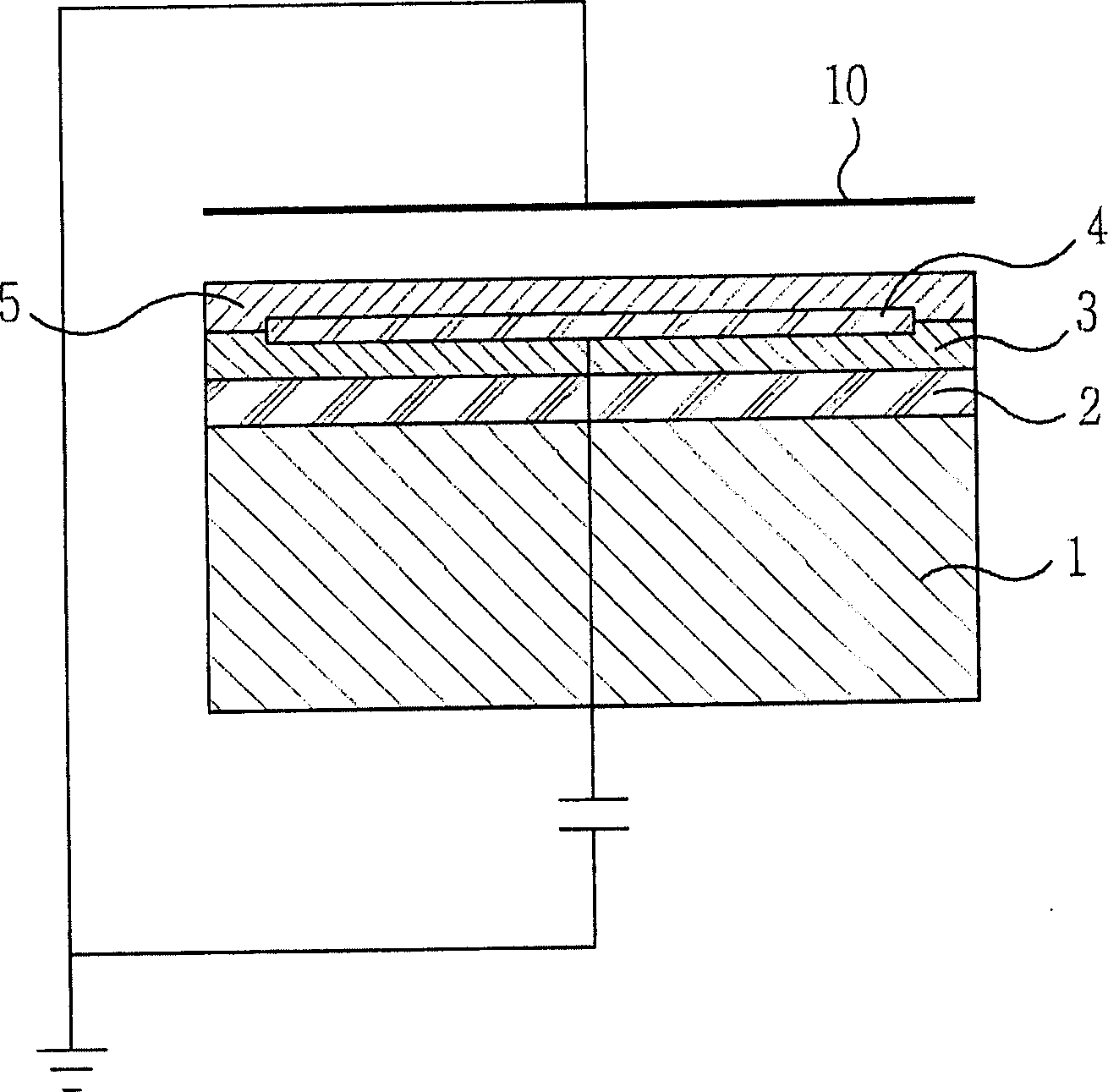

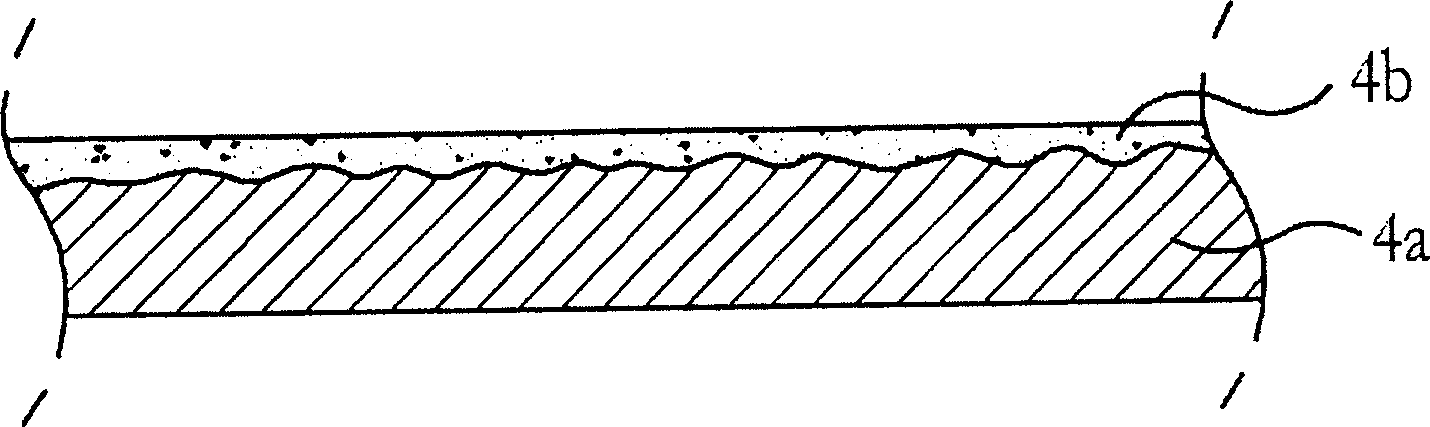

[0038] refer to image 3, the electrostatic chuck 100 according to the embodiment of the present invention includes: a supporting component 101; a lower insulating layer 110, which is formed by an insulating material coated on the supporting component 101; a plurality of electrode patterns, which are attached to the lower insulating layer 110; an insulating layer 130 formed of an insulating material coated on the electrode pattern; a junction layer formed of a junction material coated on the upper insulating layer 130; a plurality of supporting balls arranged and bonded to the junction layer 140; and a plurality of A leakage prevention dam 160 is fixedly arranged between the plurality of support balls.

[0039] The support member 101 has a flat top surface and holes formed at the upper and lower sides of the center of the support member 101 . Electrode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com