Automatic non-supporting board manufacture and system of light batten

A technology of production process and production system, applied in the field of production process of lightweight slats, can solve the problems of non-closed mold cavity, low product compactness, small extrusion stress, etc., to avoid pollution, avoid investment, and simplify process flow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0046] The light-weight slats in this embodiment take concrete hollow slats as an example, which is the same as the flow method of the existing fixed-machine unit. And other process components. The front feeding system, feeding method and the following maintenance system and maintenance method can all adopt the existing system and method, but the control system in the main production line system and the equipment and process methods on the main production line are different from the existing methods. different.

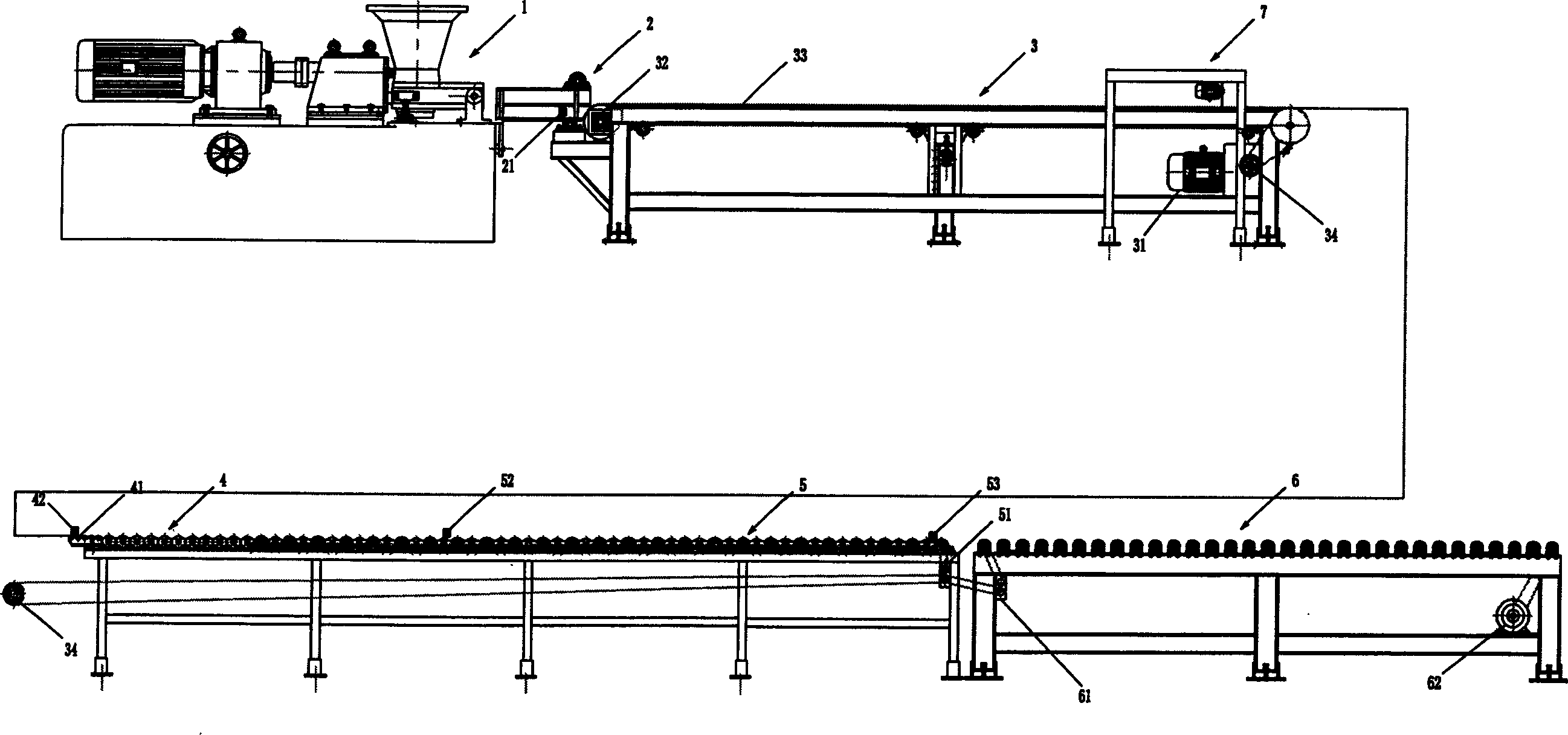

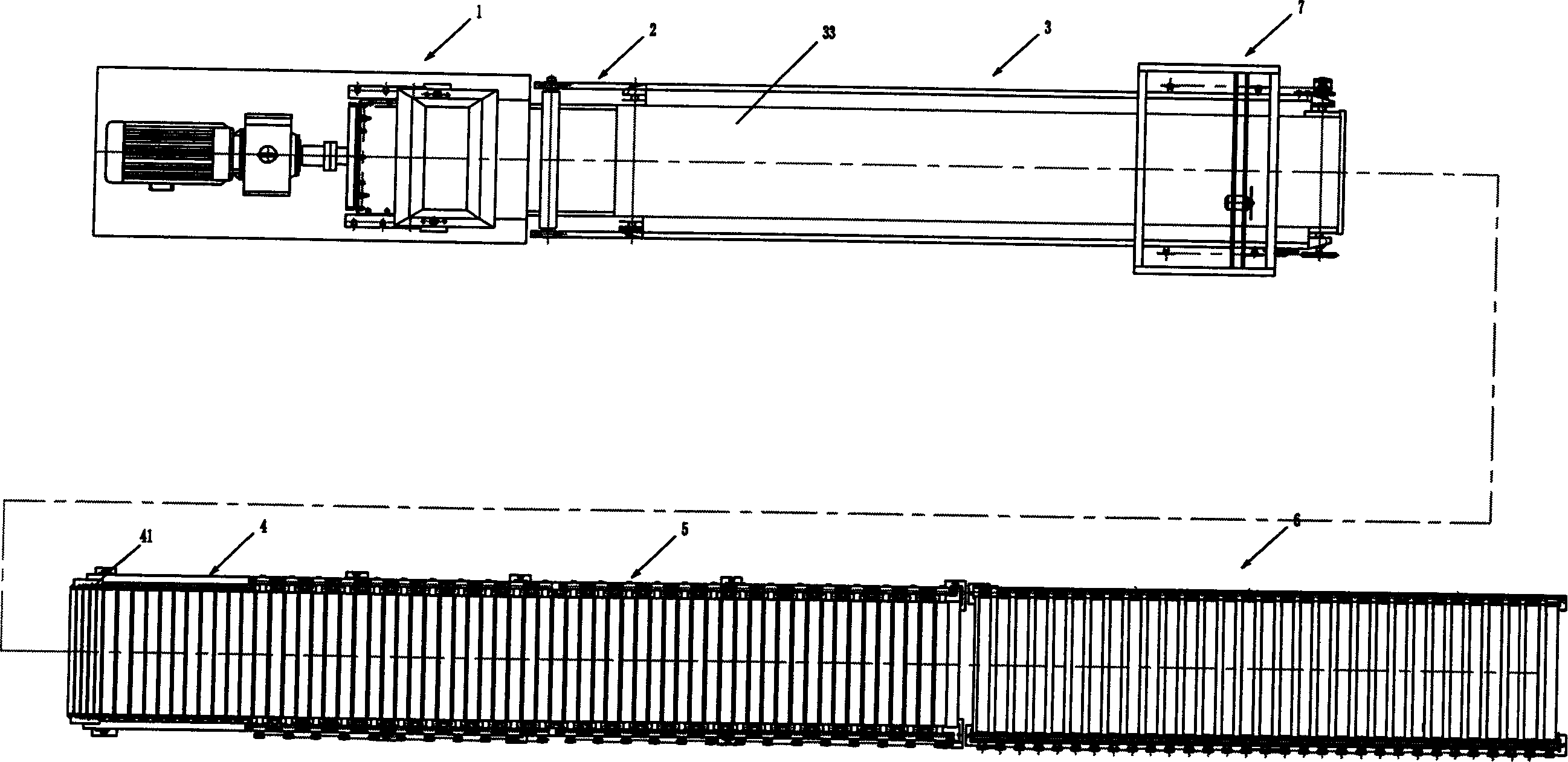

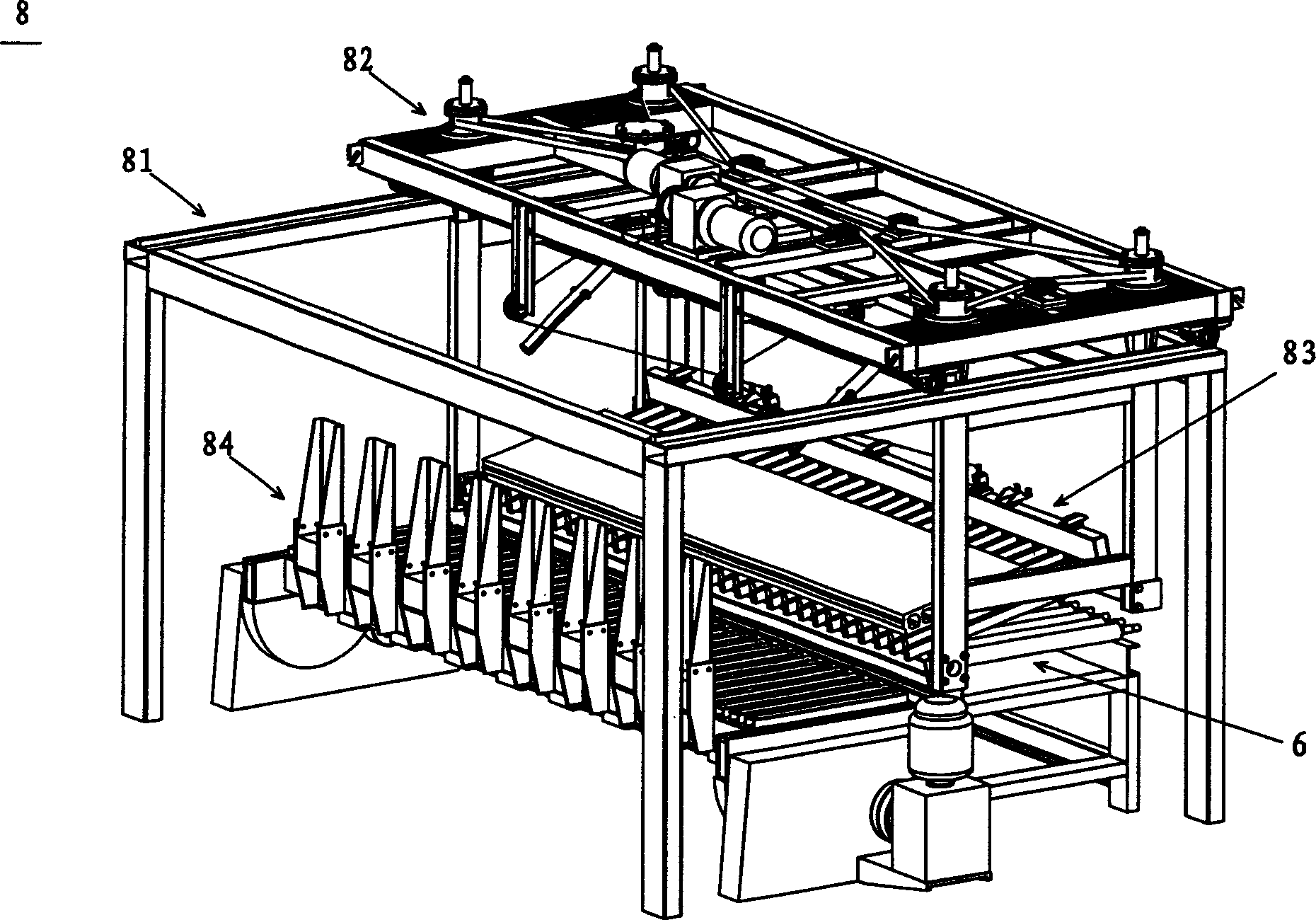

[0047] Such as figure 1 and figure 2 As shown, the main production line of the hollow slats in this embodiment sequentially includes an extrusion molding machine 1 with a bearing surface on the same plane, a guide groove 2, a synchronous belt conveyor 3, a non-powered roller table 4, a double-speed roller table 5, Move out the roller table 6, and be installed on the cutting device 7 above the synchronous belt conveyor 3 and move out the board palletizing device 8 ...

no. 2 example

[0075] This embodiment is basically the same as the first embodiment, the only difference is:

[0076] From the perspective of the main production system, the two-speed roller table has been changed to a two-speed belt conveyor to make the slats more stable during the transmission process.

[0077] Another difference is the use of another shifting palletizing device, such as Figure 5A ~ Figure 5E As shown, the board moving palletizing device 9 is composed of a board turning machine 91 and a stacking machine 92, and is placed on one side of the moving out roller table 6.

[0078] Correspondingly, the process of moving plates, stacking and unloading is different: during work, the turning plate 911 (its structure is basically the same as that of the first embodiment) of the turning plate turning machine 91 stretches into the roller table before moving the plate 6 Between the gaps between the rollers, the bearing surface is slightly lower than the surface of the rollers, such as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com