Heavy hammer and cylinder washing machine

A washing machine and hammer-type technology, which is applied to other washing machines, washing machines with containers, washing devices, etc., can solve the problems of large guide mechanism, damaged clothes, and large vertical size, so as to reduce splashing and noise, Clothes and machines are safe and the effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

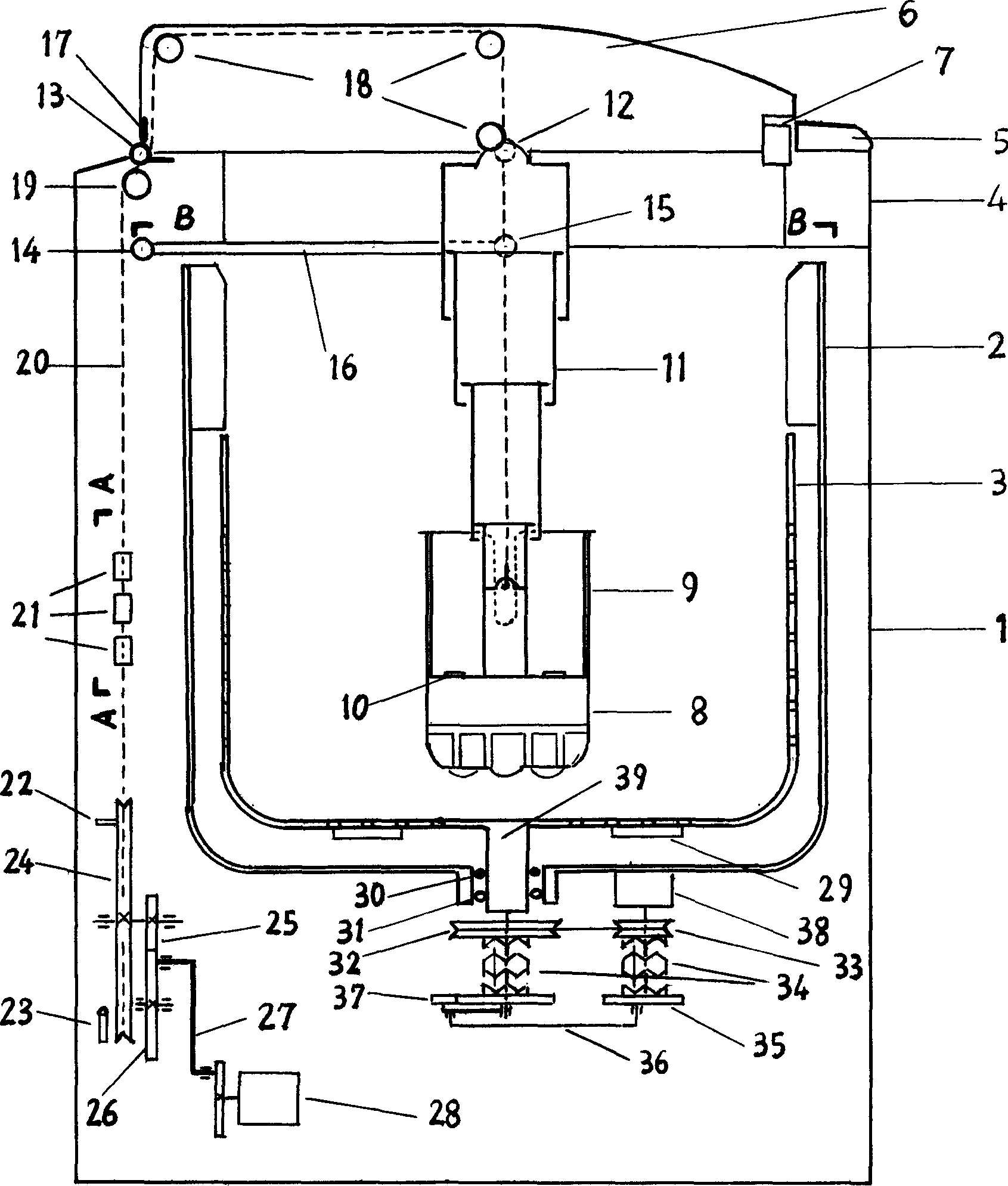

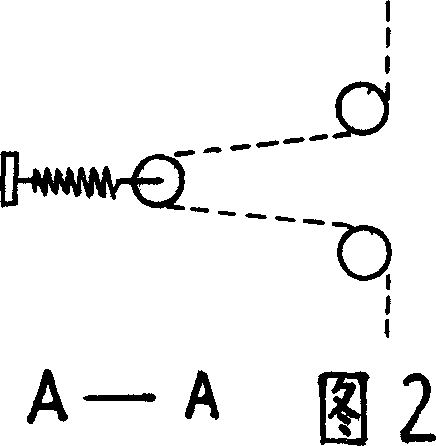

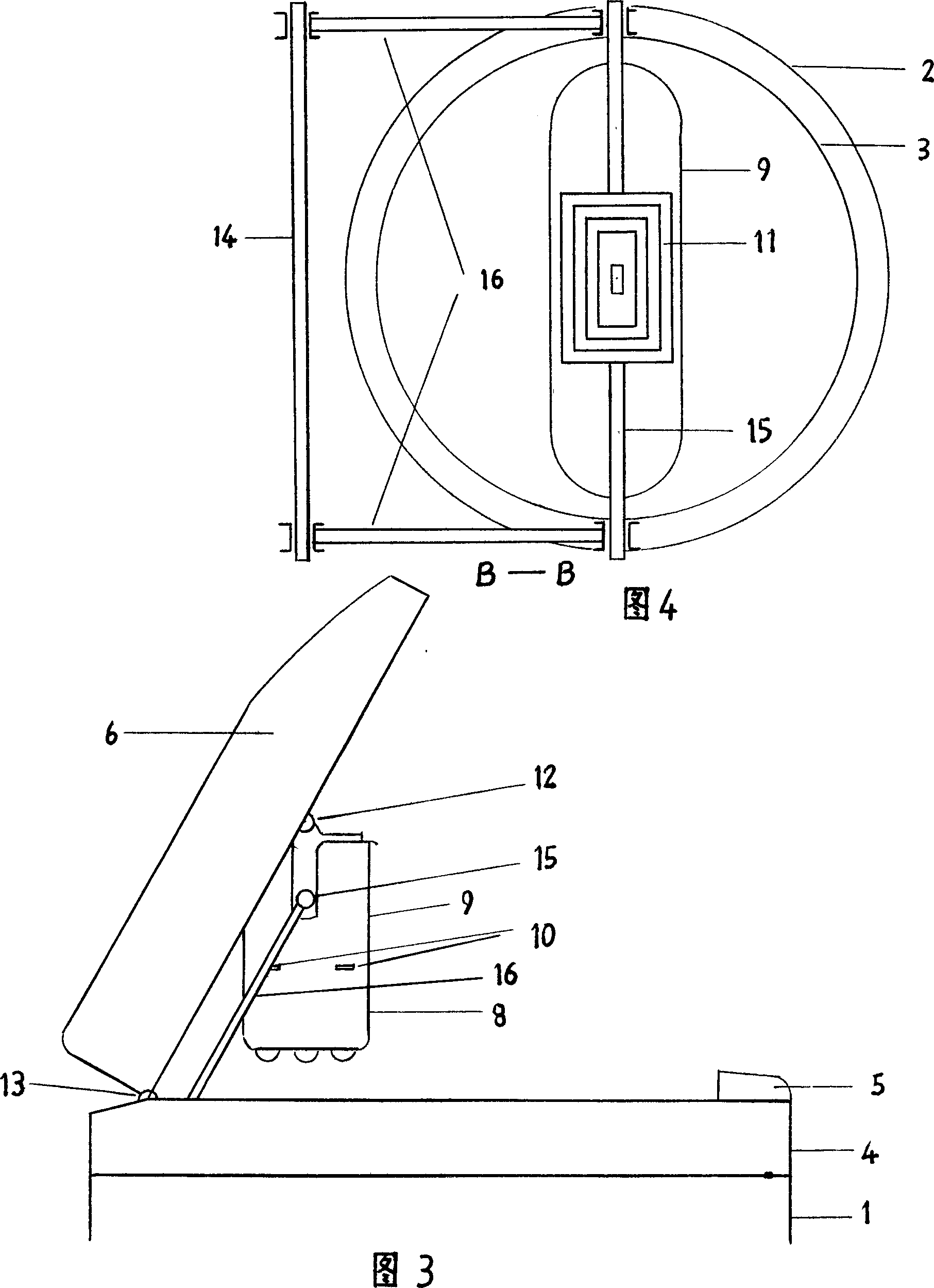

[0028] figure 1 It is a schematic diagram of the structure of a hammer-beating washing machine, without showing the inlet and outlet mechanisms, water level control mechanisms, shock absorption mechanisms, electrical control and other mechanisms. The height of the washing machine is about 85 cm, which is equivalent to that of a normal 4.2 kg automatic sleeve washing machine. Wherein the motor 28 has three kinds of rotating speeds, respectively corresponding to the striking frequency as 120 times, 60 times, 30 times per minute, and the motor 38 also has three kinds of speeds, which correspond to making the inner bucket rotate continuously at 800 times per minute and 100 times per minute through the belt pulley respectively and through the ratchet wheel every minute. Minutes 2 turns stepwise rotation. The working principle of each component will be described below in conjunction with a laundry process.

[0029] 1. Stopped state: the highest point positioning contact 22 of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com