Automatic thermostatic heater

A constant temperature heating and automatic technology, applied in induction heating devices, induction heating, measuring devices, etc., can solve the problems of easy overheating and uneven heating, and achieve the effects of energy saving, convenient operation, and easy temperature control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

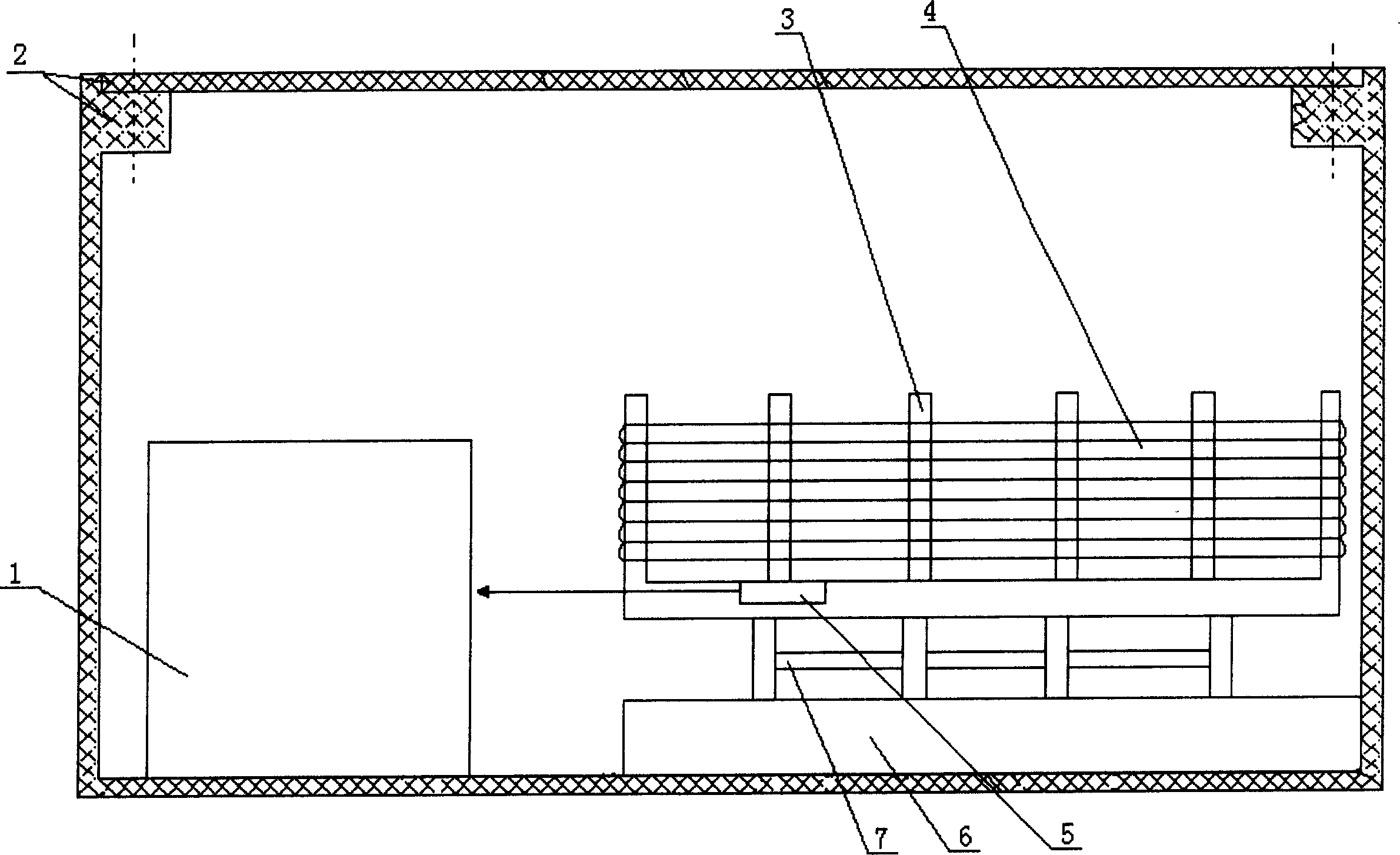

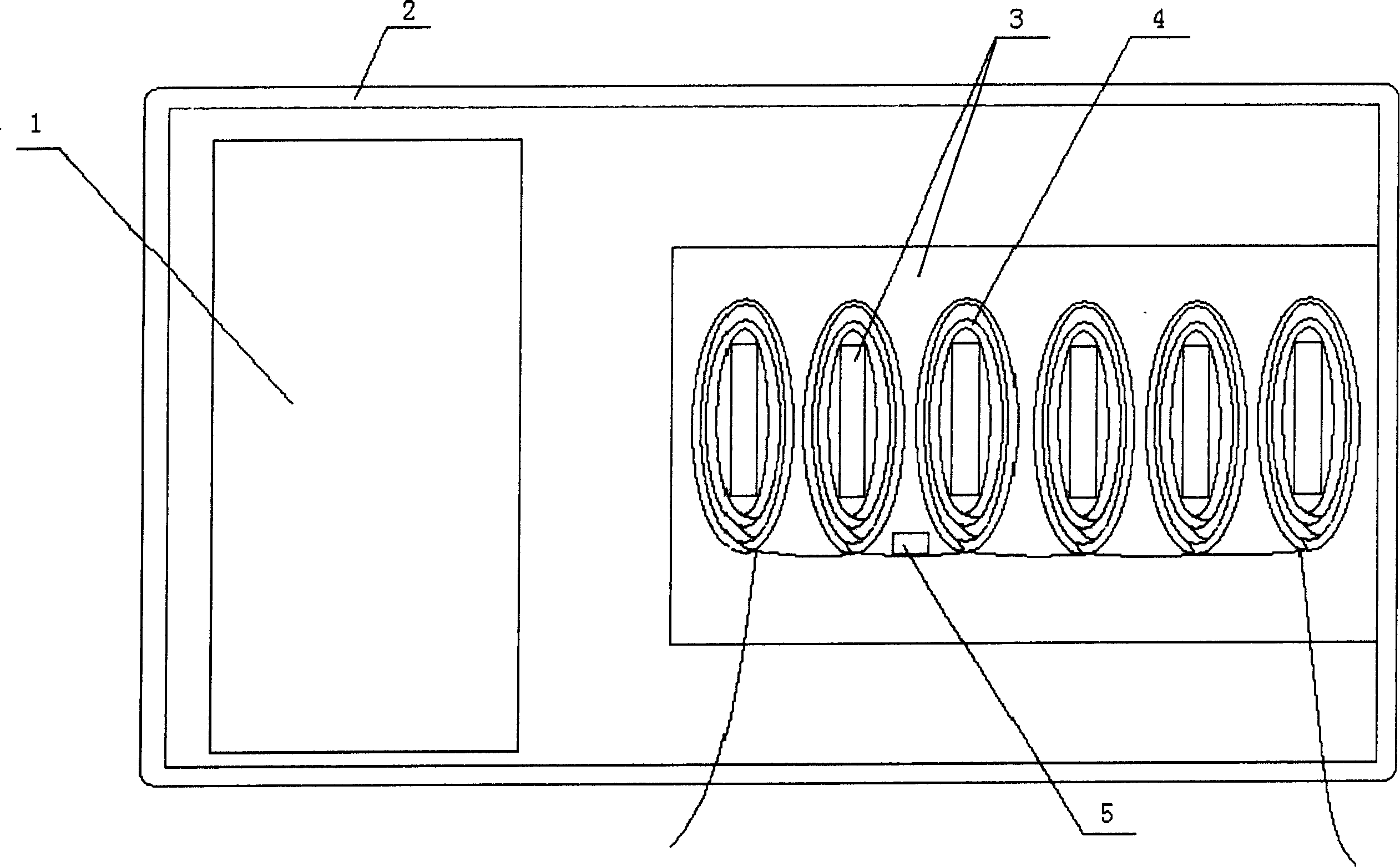

[0025] The structure of the automatic constant temperature heating device in the present embodiment is as follows: figure 1 , figure 2 As shown, it includes a casing 2 , a heater located in the casing, a heat transfer body 3 , a heating reaction coil 4 , a temperature control and temperature measuring instrument 1 and a temperature sensor 5 . The heat transfer body 3 is composed of a rectangular plate and a heat transfer sheet perpendicular to the rectangular plate. The material is cast aluminum, and there are six heat transfer sheets; Out of the shell 2. The heater is composed of an insulating base 6, a ceramic heating element 7 installed on the base, and a wire assembly connecting the ceramic heating element and a power supply, and the rectangular plate of the heat transfer body 3 is installed on the heater. Both the temperature sensor 5 and the temperature control and temperature measurement instrument 1 are commercially available. The temperature sensor 5 is installed i...

Embodiment 2

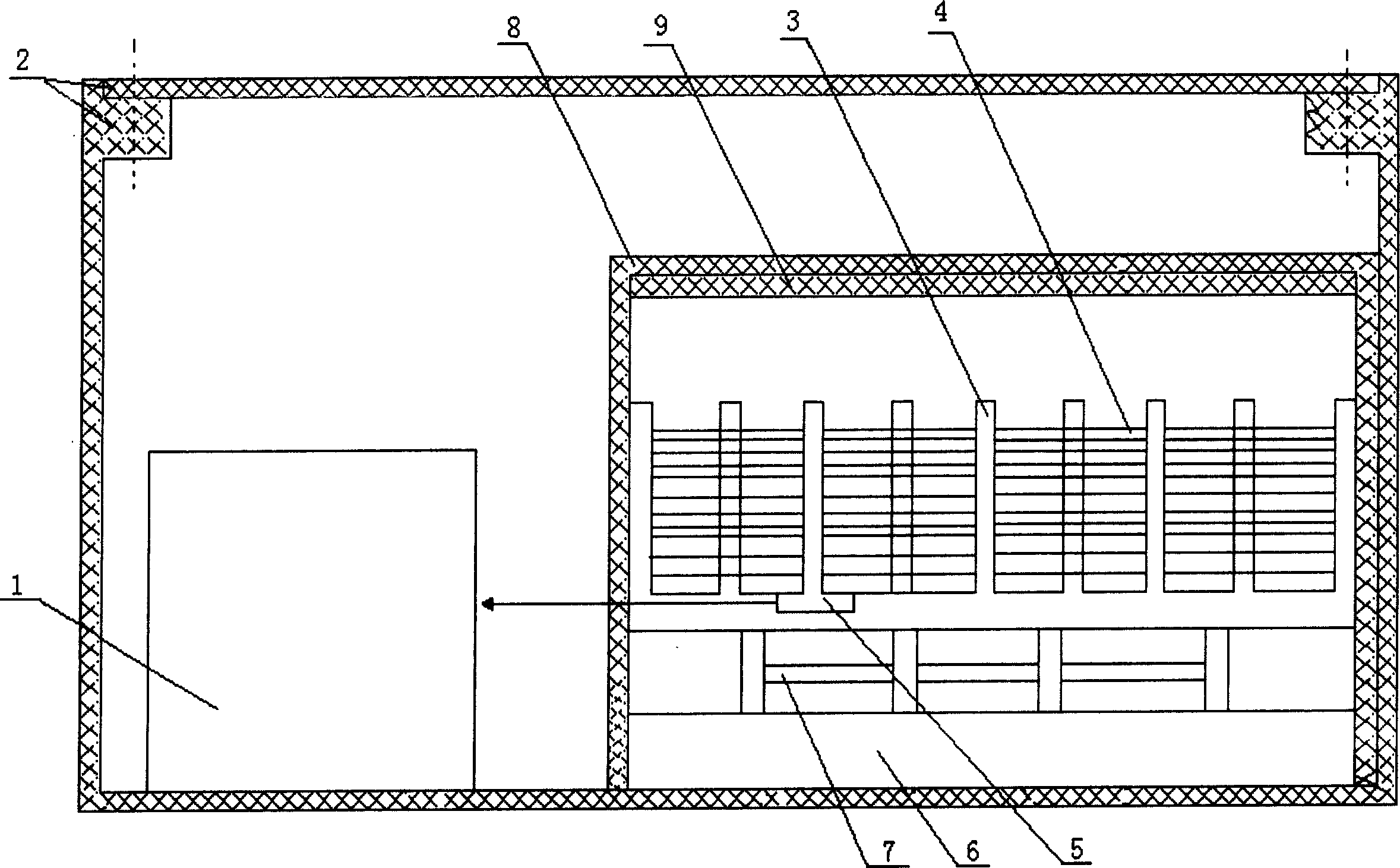

[0027] The structure of the automatic constant temperature heating device in the present embodiment is as follows: image 3 , Figure 4 shown. The difference from Example 1 is: 1. The heat transfer body 3 has nine heat transfer sheets, and the heating reaction coil 4 is wound on the heat transfer sheet at intervals, and the heat transfer sheet wrapped with the heating reaction coil is located between two sheets that are not wound with a heating coil. between the heating pads of the reaction coil. 2. The insulation cover 8 made of asbestos cardboard is installed, and the insulation cover 8 is set on the heat transfer body and the heater. Its shape and size match the shape and size of the combination of the heat transfer body and the heater; the inner wall of the top of the insulation cover Covered with a thermal insulation layer 9 made of polymer foam material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com