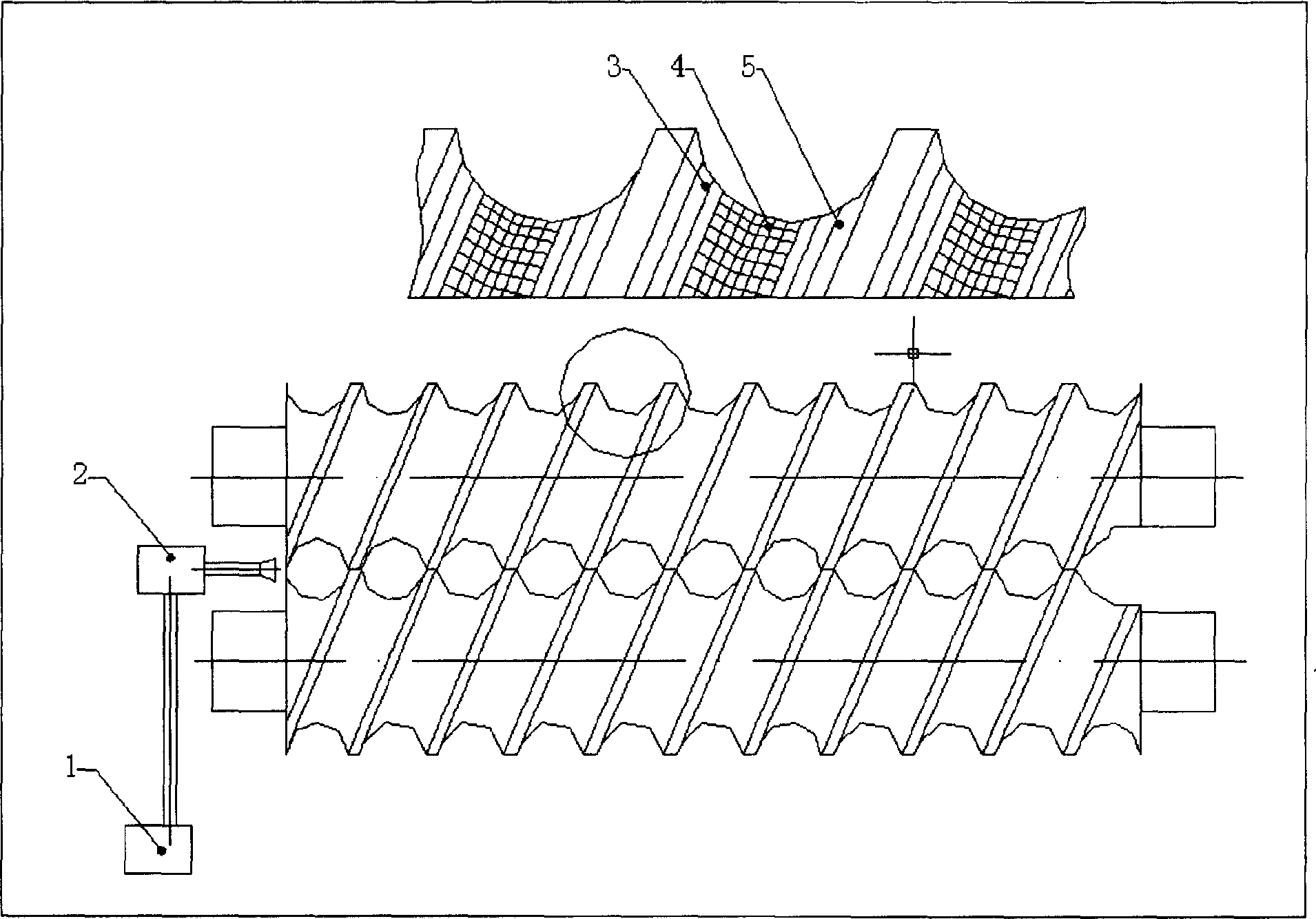

Hand kneading type steamed bread machine

A steamed bread machine and a steamed bread technology are applied in the field of steamed bread machines to achieve the effects of avoiding food waste, saving food, and being easy to operate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0015] The working process of the hand kneading steamed bun machine is: check the machine status, if there is no abnormality, turn on the power, the air compressor will start at any time when the air pressure is lower than the normal value, and it will automatically shut down when the set pressure is reached. , start the steamed bun machine, the feeder starts to supply noodles to the former, the solenoid valve 1 conducts the airflow, and the oil spray gun 2 starts to spray highly atomized clear oil at the front end of the former to prevent the noodles from sticking to the former. Feed in one piece of dough every rotation, rotate 7 to 8 times, drop the kneaded steamed bun base into the discharge chute, from which the steamed bun base rolls and slides into the steamer, and presses the part with the "small tail" of the steamed bun on the bottom with your hands. Can.

[0016] During the forming process, when the dough moves in a circular cavity formed by the spiral curved surfaces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com