Pollution free refuse transfer station

A technology of garbage transfer vehicles and transfer stations, which is applied in the direction of garbage transmission, garbage collection, transportation and packaging, etc., and can solve the problems of high labor intensity of sanitation workers, odor pollution of the environment, unhygienic and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

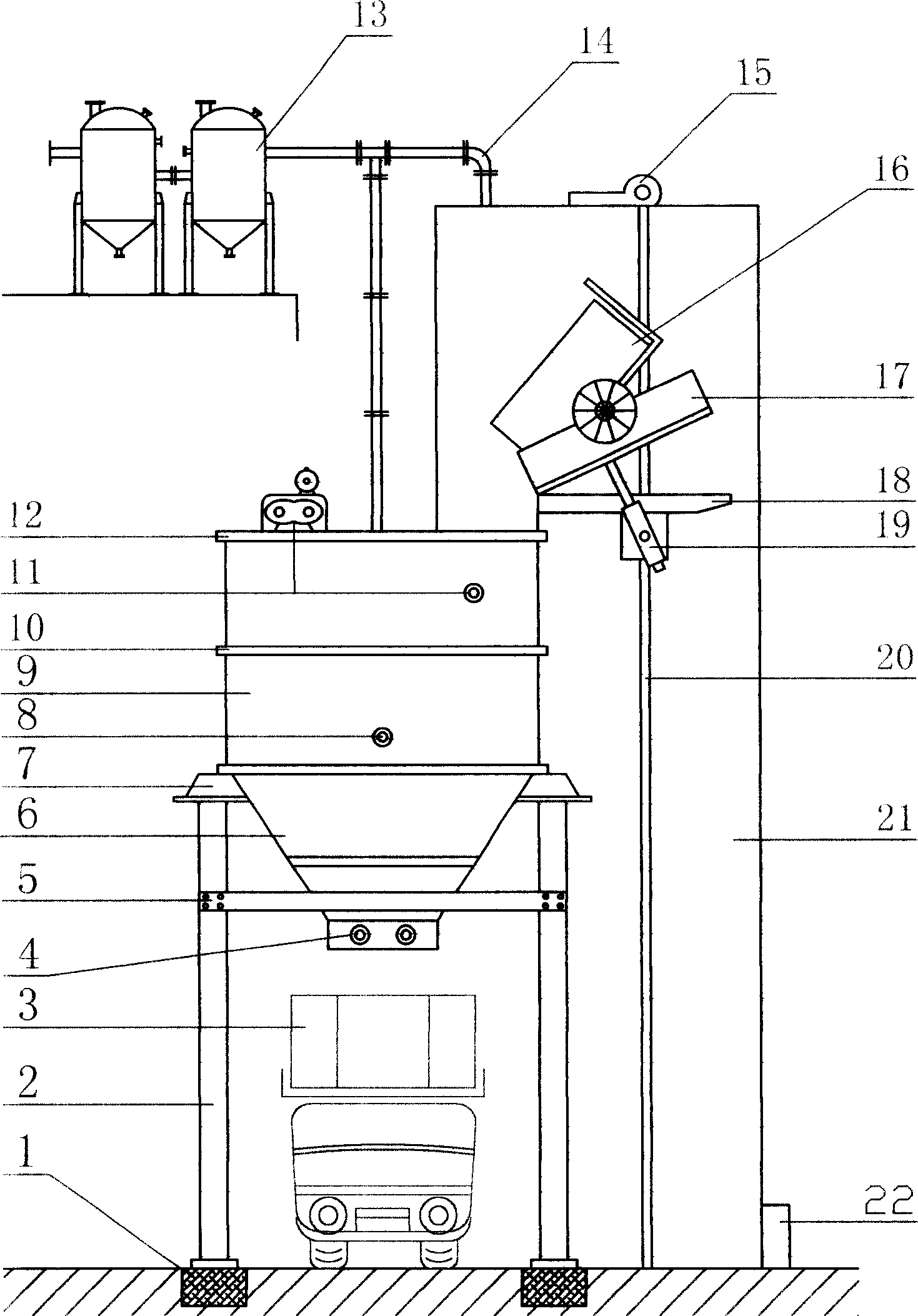

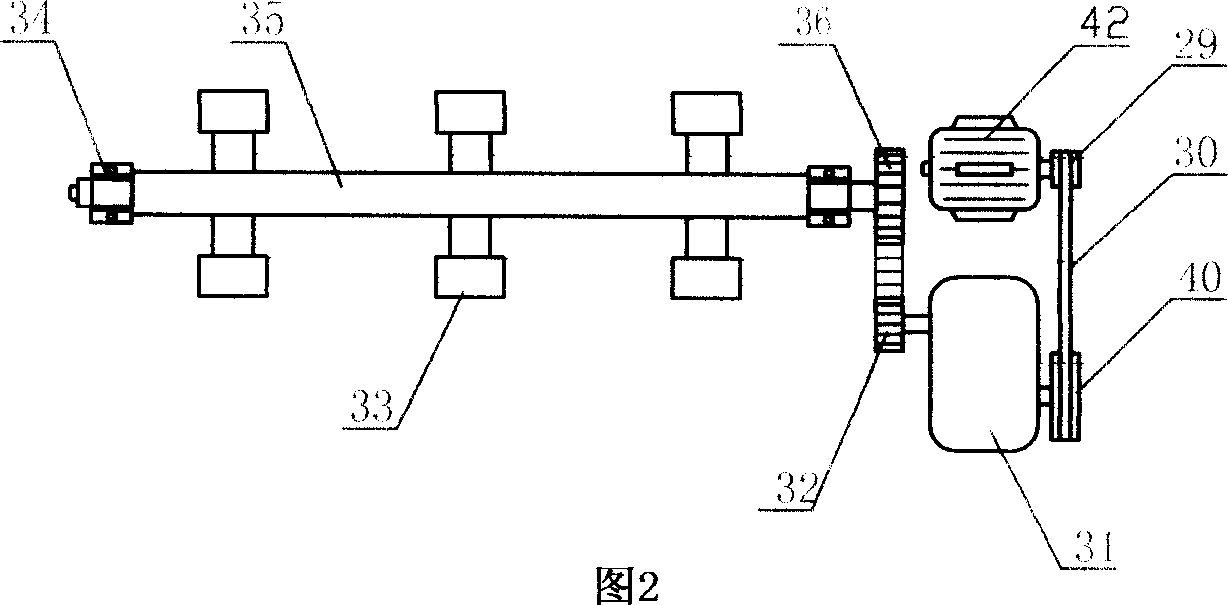

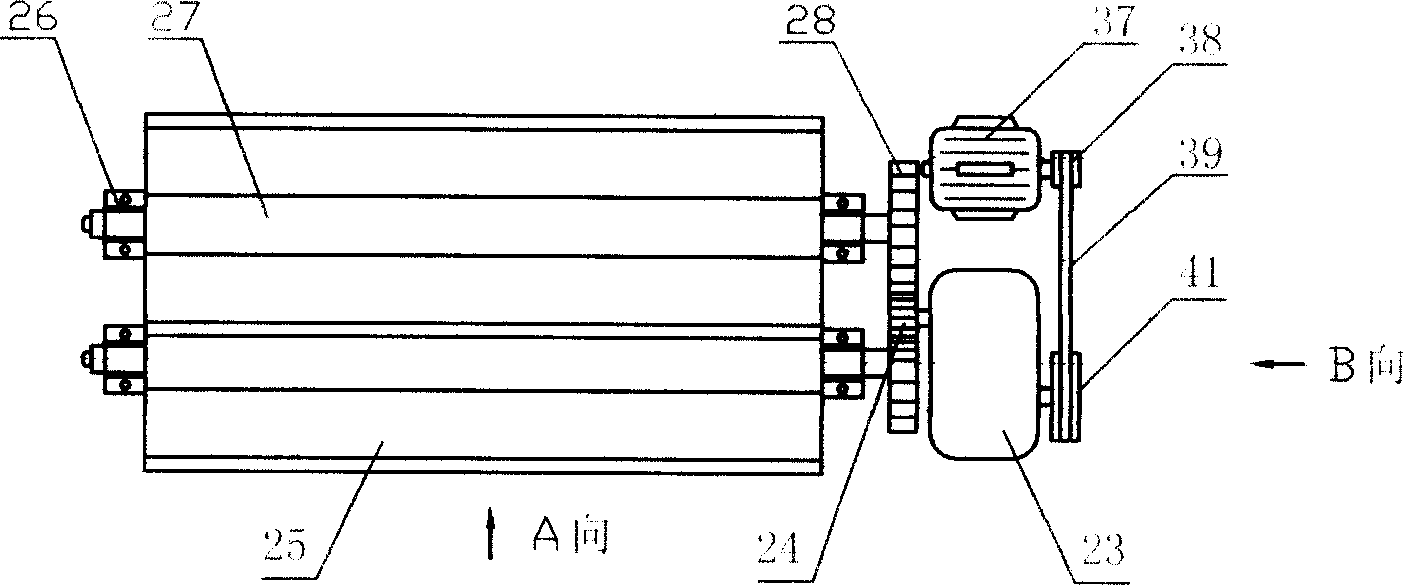

[0011] The present invention is described in detail below in conjunction with accompanying drawing:

[0012] Such as figure 1 ,figure 2, image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 7 Shown, the present invention comprises pallet lifting mechanism, and structural feature is to also comprise 1) a lifting shaft 21, and this lifting shaft is preferably airtight, and pallet lifting mechanism can park and move up and down in this lifting shaft, and pallet lifting The mechanism includes a lift 15 and a hanging basket support 18 that can be driven up and down by the lift 15. The hanging basket support 18 is provided with a tipping bucket fence box 17, and the lower part of the hoistway 21 is provided with a trolley entrance and exit 22, so that the trolley can enter and exit the dumping bucket smoothly. The fence box 17, the bucket fence box 17 is equipped with a hydraulic self-unloading device 19, the hydraulic self-unloading device adopts an existing structure such a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com