Permanent magnet synchronous high-speed tractive machine without gear wheel

A technology of gear traction machine and permanent magnet synchronous motor, which is applied in the direction of clockwork mechanism, elevators in buildings, hoisting devices, etc., can solve the problem that the strong power of high-speed elevator traction machines cannot be satisfied, and the motor bearings are prone to early wear. , easy to produce vibration and other problems, to achieve the effect of promoting the application value and market prospects, improving the overall operating performance, and convenient installation and adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

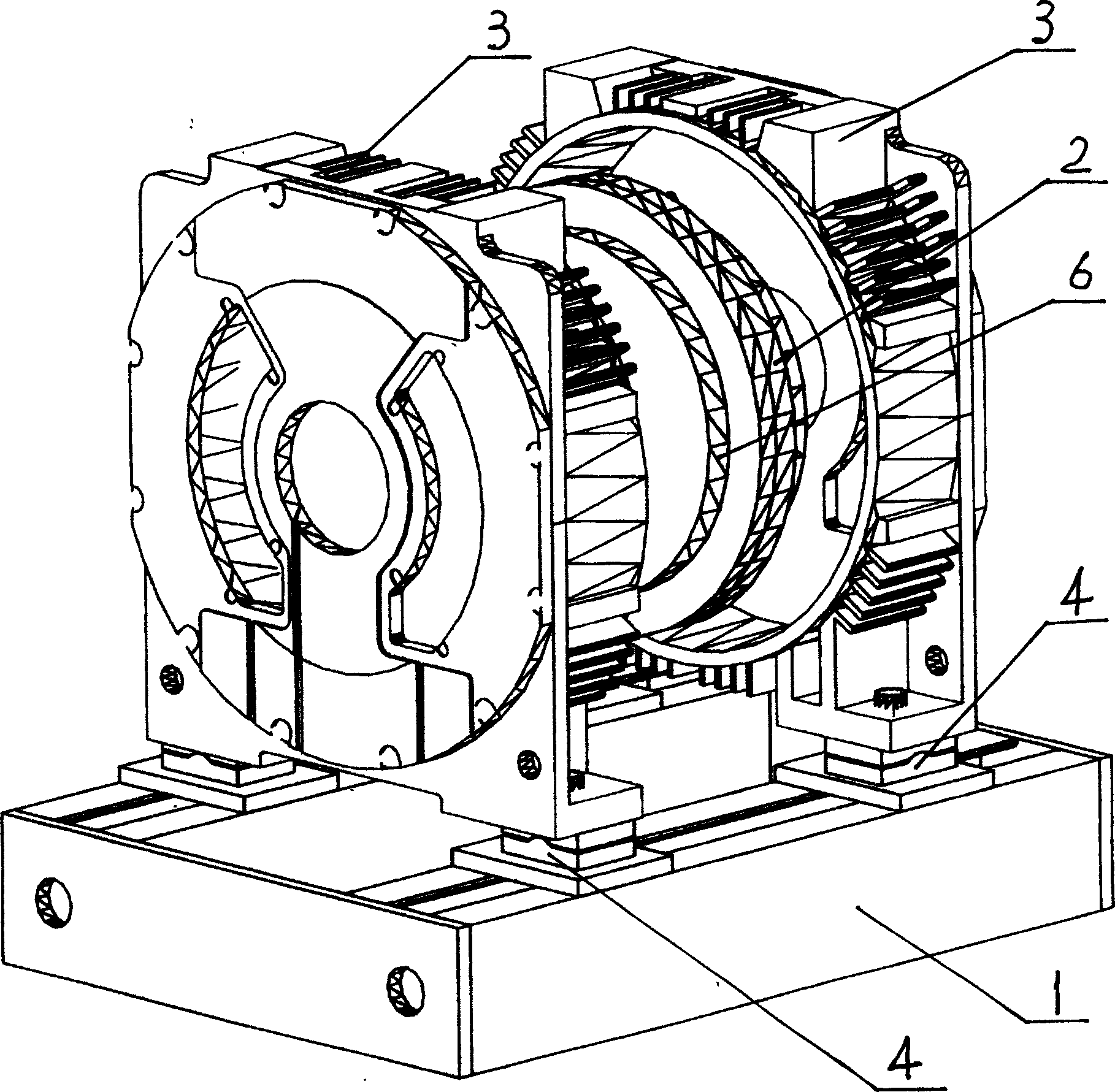

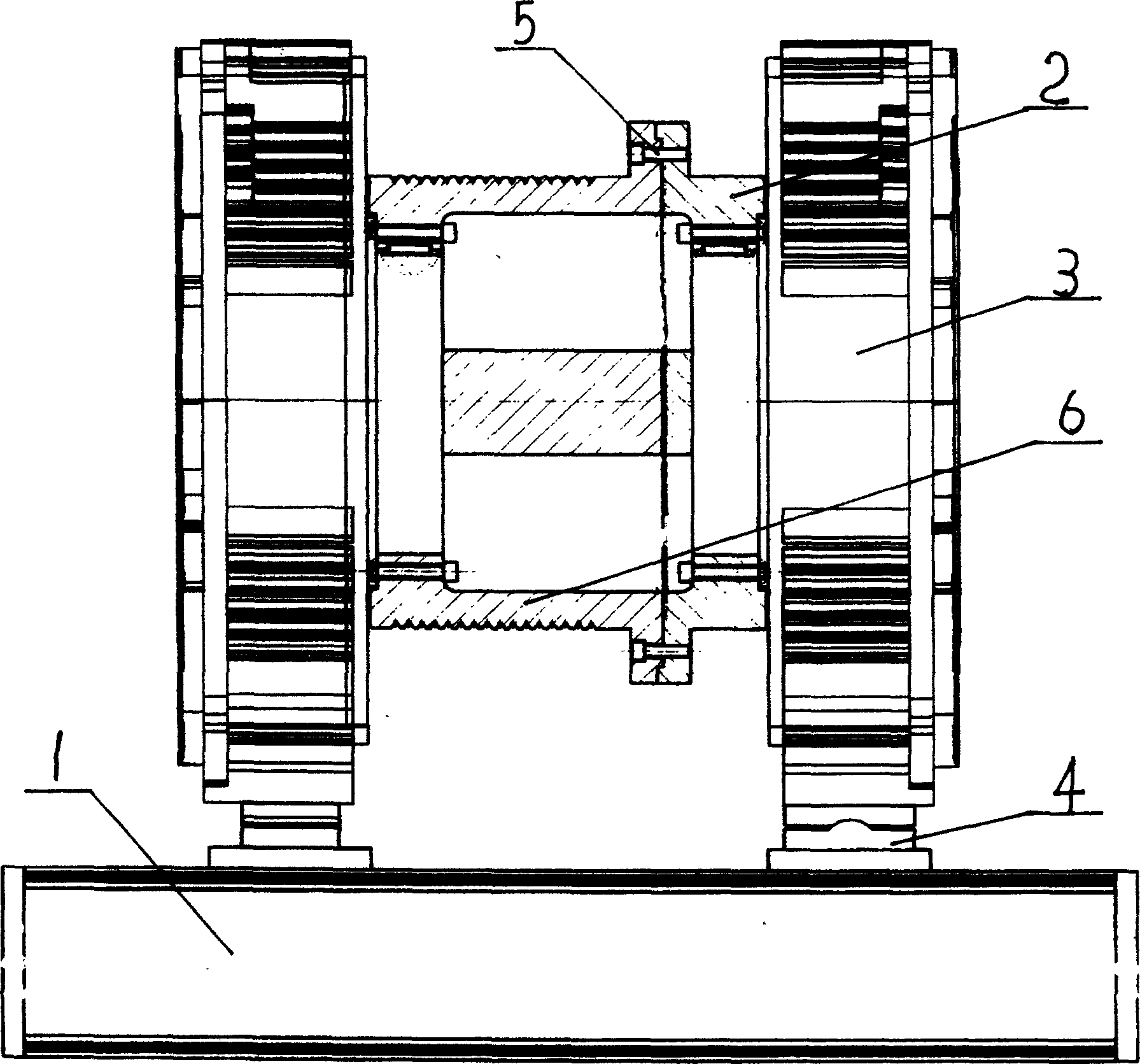

[0009] A traction sheave 6 is installed in the middle of two thin permanent magnet synchronous motors 3, and two thin permanent magnet synchronous motors (one forward and one reverse) are directly installed and connected to the traction sheave 6 on the shaft of one motor, and the shaft of the other motor First install and connect the installation accessory 2, and then connect and fix the traction sheave 6 and the installation accessory 2. The traction sheave 6 and the installation accessory 2 are respectively provided with matching positioning notches to ensure that the traction sheave 6 and the installation accessory 2 are coaxial Center, connect and fix the traction sheave 6 and the installation accessory 2 with bolts. The bottoms of the two thin permanent magnet synchronous motors 3 are respectively provided with two strip-shaped concave-convex arc surface contact connection bases 4 for supporting and installing and adjusting the traction machine. The base is vertical, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com